LED driving circuit

An LED driver and circuit technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of human ear noise, long conduction time, low circuit operating frequency, etc., to avoid noise, improve efficiency, and reduce switching. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

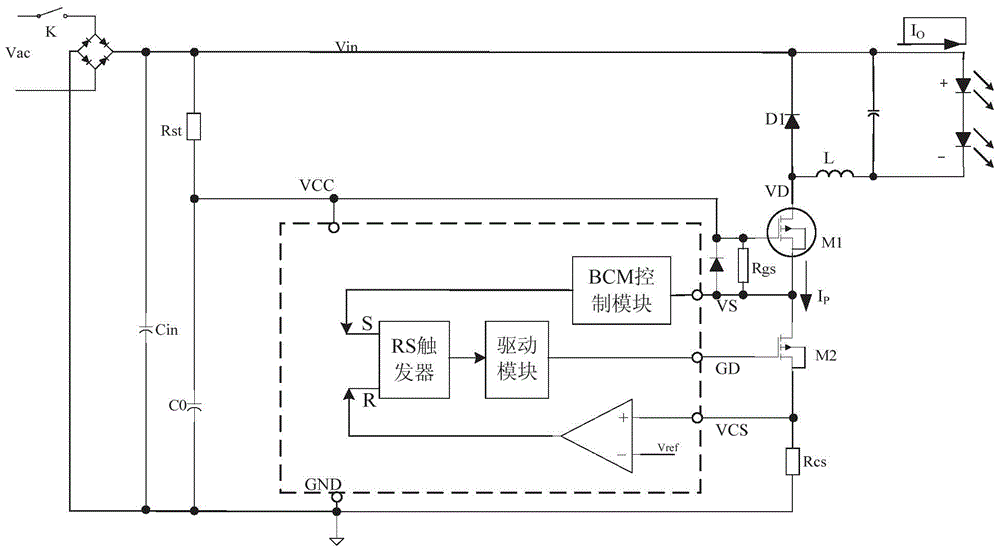

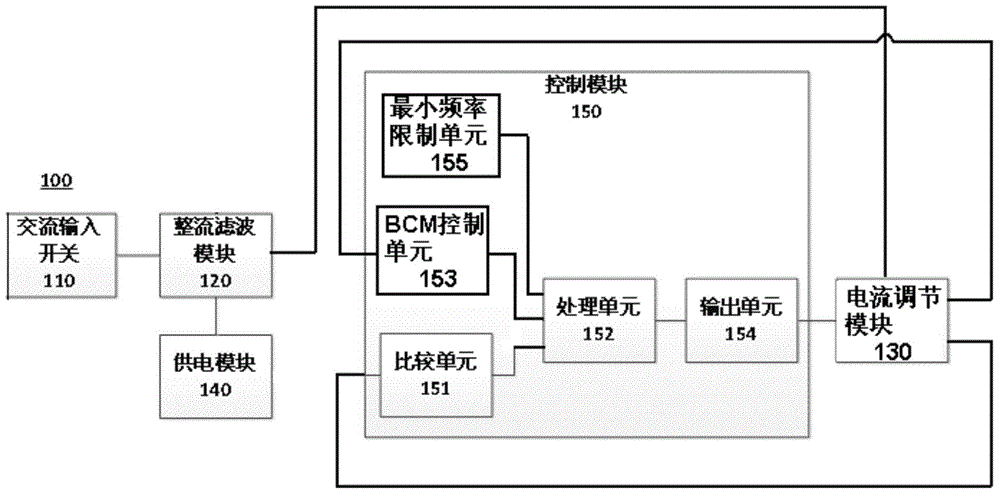

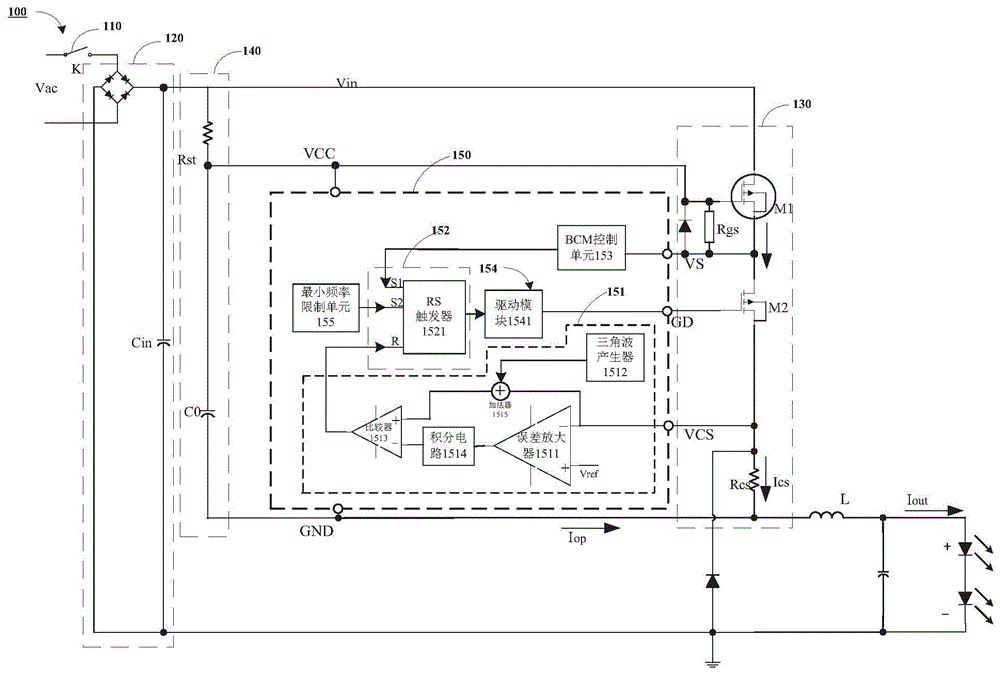

[0025] The invention aims at the problem that the conduction loss of the high-voltage MOS is increasing due to the voltage drop in the prior art; the minimum operating voltage of the circuit is high and the operating frequency of the circuit is too low when the input voltage is low, and there may even be human ear noise. An LED drive circuit adopts an automatic selection mode to make the circuit work in BCM mode at high input voltage to reduce switching loss; and automatically enters CCM mode at low input voltage, which can effectively improve efficiency at low voltage operation and reduce The minimum operating voltage is guaranteed, and noise can be avoided at the same time.

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0027] figure 2 It is a functional block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com