Gas consumption prediction model establishing method and device based on hot blast stove group

A predictive model and hot stove technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limited scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

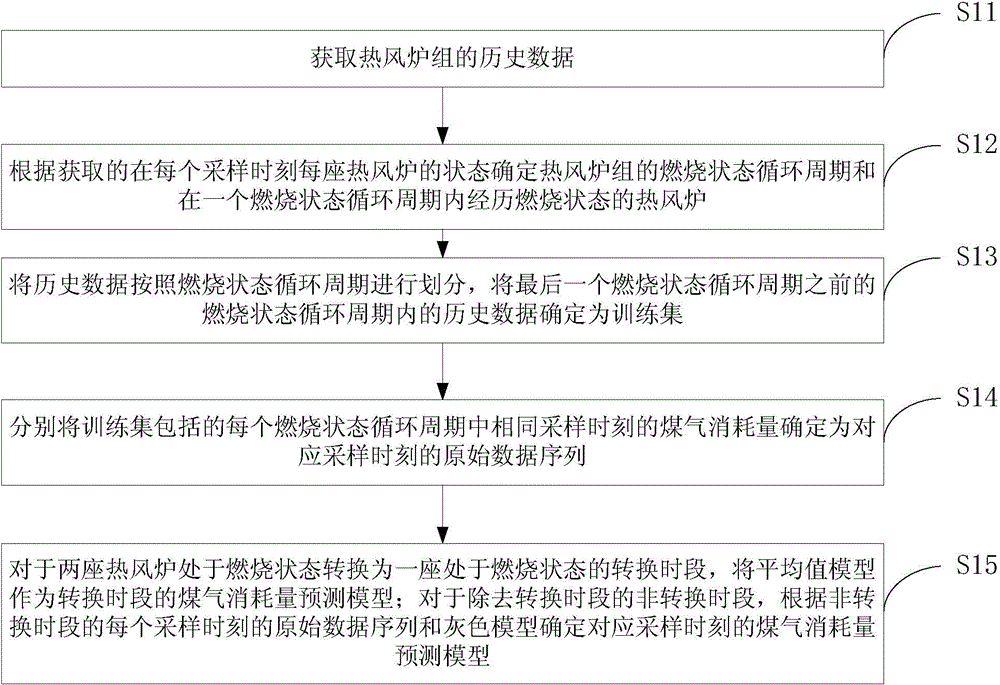

[0063] In view of the problem in the prior art that the method for establishing a gas consumption prediction model based on a hot blast stove group has a very limited scope of application, an embodiment of the present invention provides a method for establishing a gas consumption prediction model based on a hot blast stove group. The process flow of the method Such as figure 1 As shown, the execution steps are as follows:

[0064] S11: Obtain historical data of the hot blast stove group.

[0065] When the hot blast stove group continuously supplies air to the blast furnace, it will record the historical data of the hot blast stove group, which includes the gas consumption of the hot blast stove group at each sampling time and the status of each hot blast stove in the hot blast stove group. Gas is consumed only when the hot blast stove is in the burning state, so it is necessary to obtain the status of each hot blast stove.

[0066] S12: Determine the combustion state cycle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com