Hemispherical ideal cemented particle contact shear, bending and torsion test device

A technology of cementing particles and testing devices, applied in the direction of testing material strength by applying a stable torsion force, testing material strength by applying a stable bending force, testing material strength by applying a stable shear force, etc., and can solve the problem of shearing under force , turning, torsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

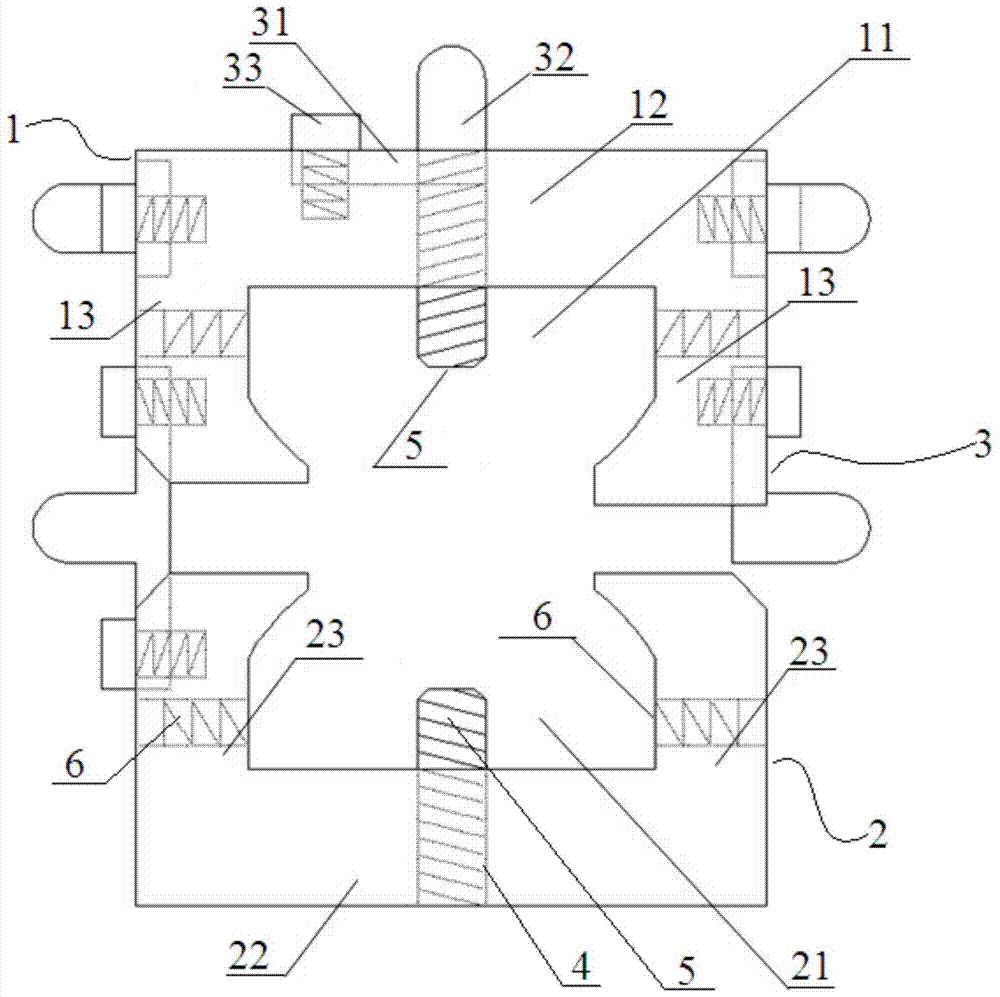

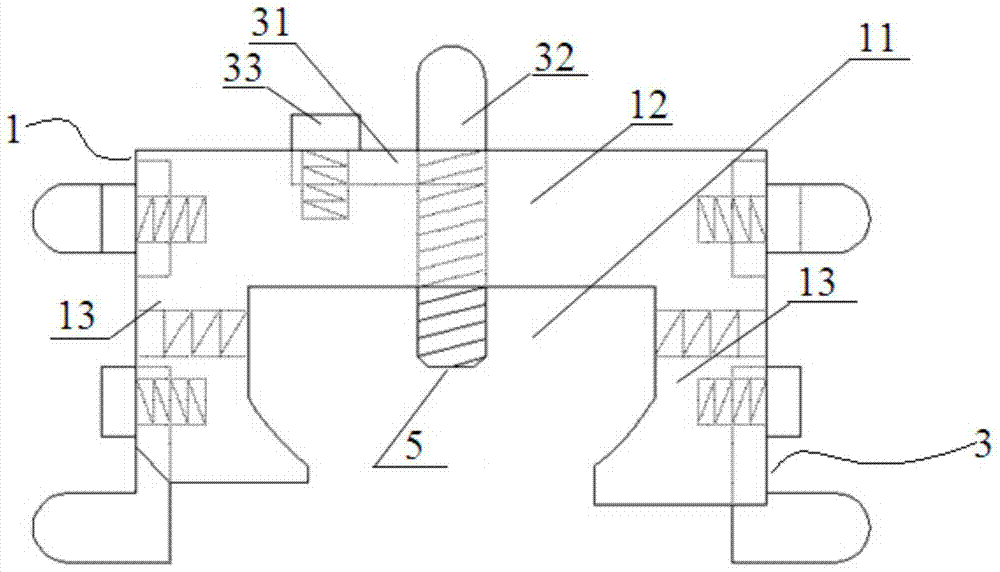

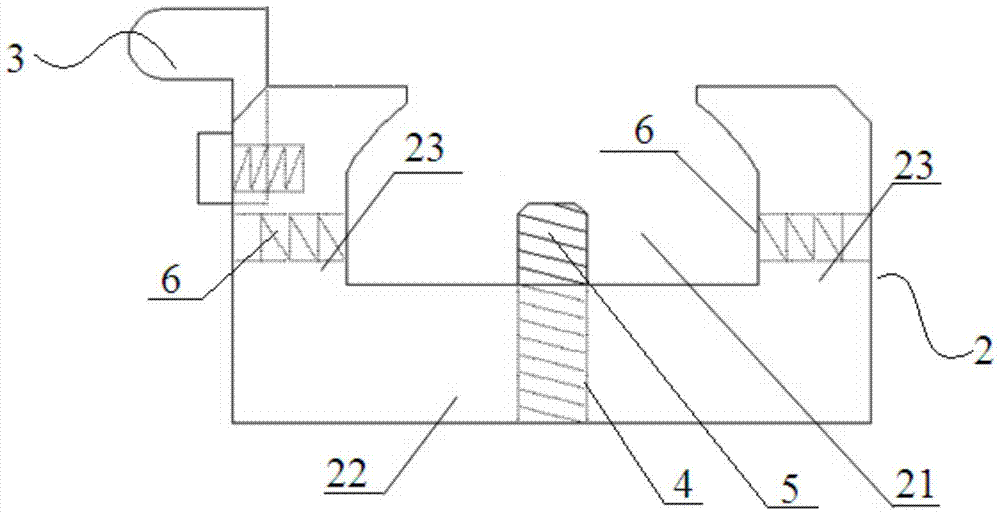

[0033] Such as Figure 1 to Figure 11 As shown, a hemispherical ideal cement particle contact resistance test device for shear, bending and torsion includes an upper clamping member 1 and a lower clamping member 2 aligned up and down. The upper clamping member 1 is provided with an upper notch on the lower side 11. The upper side of the lower clamping member 2 is provided with a lower notch 21. The upper notch 11 communicates with the lower notch 21 and forms a clamping space for clamping ideal cemented particles in the hemispherical shape. The upper clamping member 1 and the lower The outer side of the clamping member 2 is provided with a force applying member 3 for applying force.

[0034] The upper clamping member 1 includes an upper top plate 12 and two upper side panels 13 connected to both sides of the upper top plate 12, and an upper notch 11 is formed between the two upper side panels 13 and the upper top plate 12; the lower clamping member 2 It includes a lower top boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com