A detection system and production line for detecting the liquid level in a sealed tank

A detection system and liquid level technology, applied in the direction of measuring devices, liquid level indicators, engine lubrication, etc., can solve the problems of insufficient filling, poor corporate image, and difficult detection in time, so as to avoid corporate losses and bad Influence, meet high-speed mass production, highlight the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

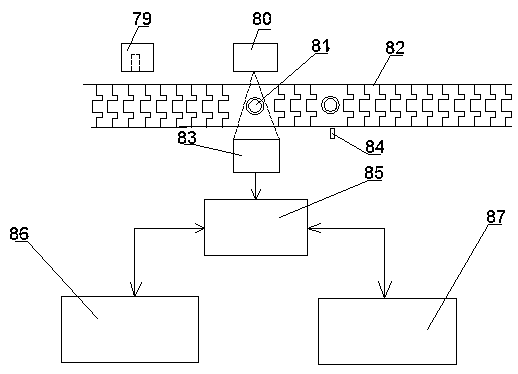

[0038] A detection system for detecting the liquid level in a sealed pop can, comprising

[0039] The X-ray emitting module 80 is used to send X-rays to the detected pop cans;

[0040] The X-ray receiving module 83 is used to receive the X-rays transmitted from the detected pop cans;

[0041]The system processing module 85 analyzes and processes the X-ray signal received by the X-ray receiving module 83 and feeds the signal back to the system display module 86, and also controls the action of the system rejecting module 79;

[0042] The system display module 86 is used to display the data processed by the system processing module 85, the number of processed pop cans and the number of unqualified and rejected pop cans;

[0043] The system rejecting module 79 receives the sending ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com