A double volute swirling pulverized coal burner with natural gas nozzle and pre-combustion chamber

A pulverized coal burner and natural gas technology, applied in the combustion of gaseous fuel and powder fuel, the combustion of block fuel and powder fuel, the combustion of block fuel and gaseous fuel, etc., can solve the problem of volatile matter release rate low, not easy to ignite and burn out, and difficult to peak-shaving operation, to achieve the effect of simple structure, stable combustion, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

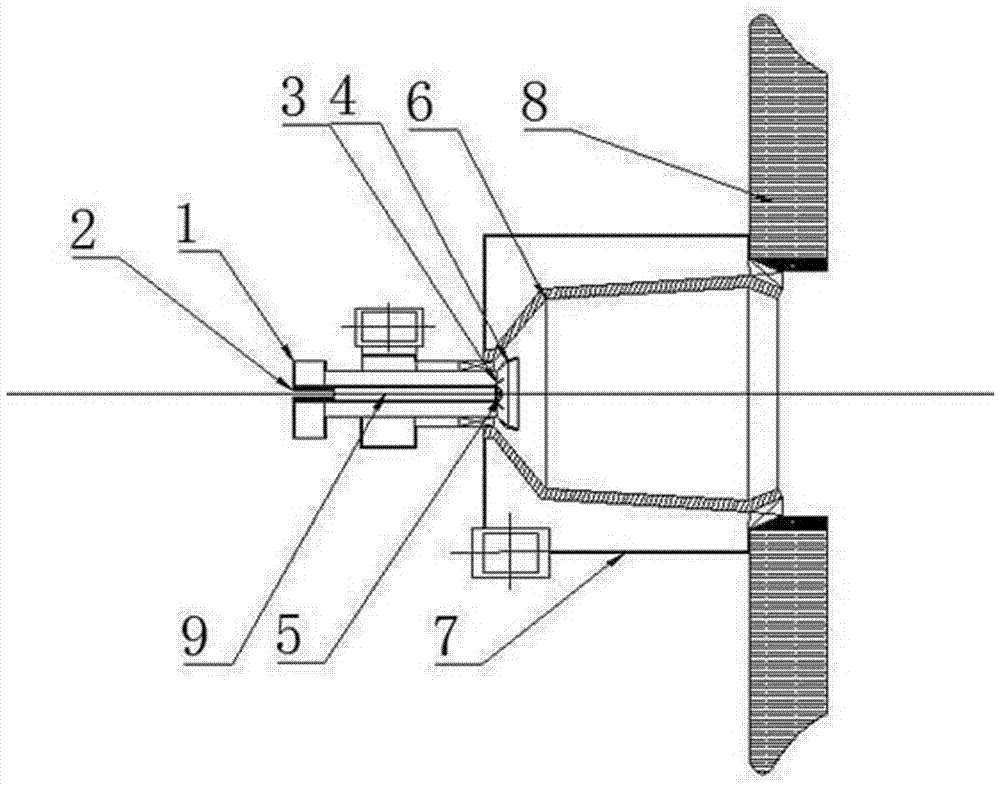

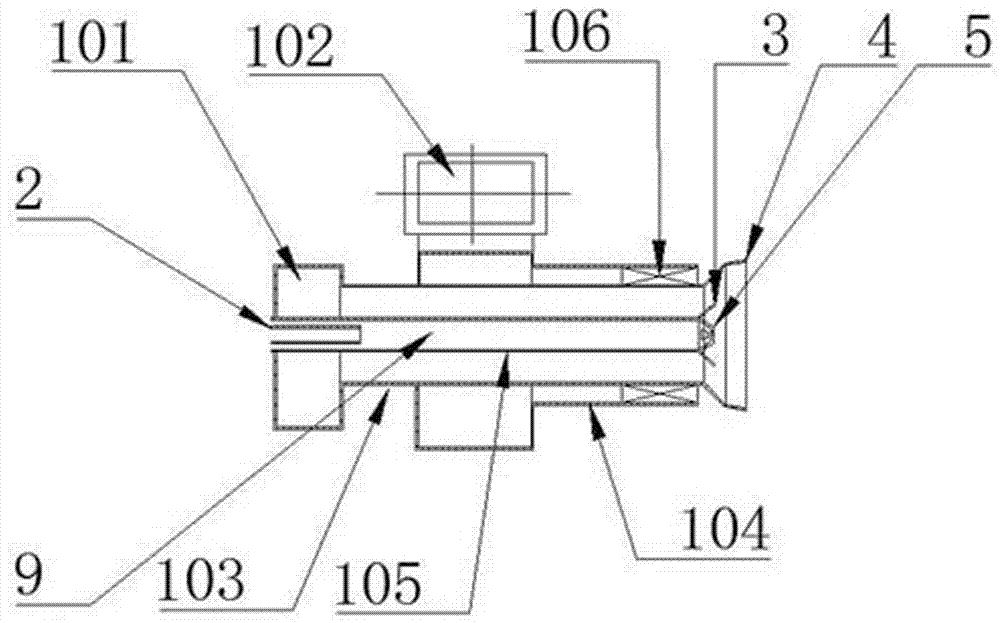

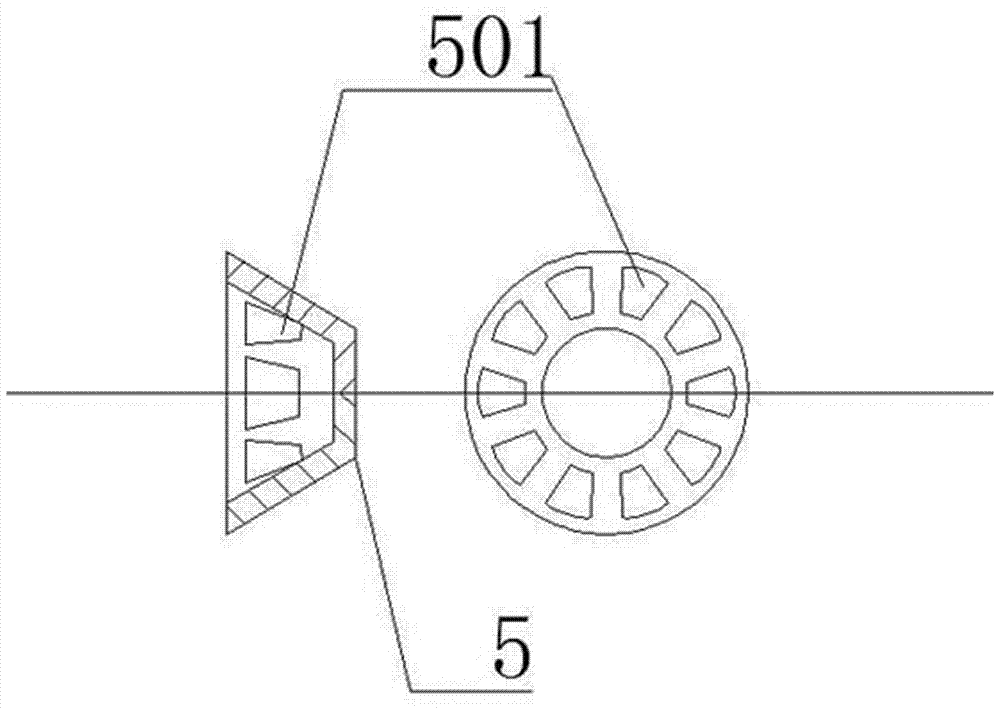

[0028] Embodiment: A double-volute swirling pulverized coal burner with a natural gas nozzle and a pre-combustion chamber, as shown in the figure, including a double-volute burner 1, a natural gas nozzle 2, and a central air pipe flare 3 , Primary air pipe flaring 4, natural gas-air nozzle 5, pre-combustion chamber 6 and rear secondary air duct 7. Double volute combustor 1 comprises primary air volute 101, secondary air volute 102, front secondary air duct 104, front secondary air swirl blade 106, primary air duct 103 and central air duct 105, front secondary air swirl Flow blades 106 are arranged at the outlet of the front secondary air duct 104 . The natural gas nozzle 2 is arranged in the central air duct 105 of the double volute burner 1 . The natural gas-air nozzle 5 is arranged at the outlet of the central air pipe 105 ; the flare 3 of the central air pipe is arranged at the outlet of the central air pipe 105 . The primary air flaring port 4 is arranged at the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com