Reversing reciprocating screw pumping unit and usage method thereof

A technology of pumping unit and reversing mechanism, which is used in earth-moving drilling, production of fluid, wellbore/well components, etc., can solve the problems of large load change, large installation workload, large installed power, etc., and achieves simple mechanism, Smooth motion and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

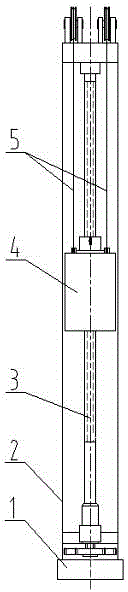

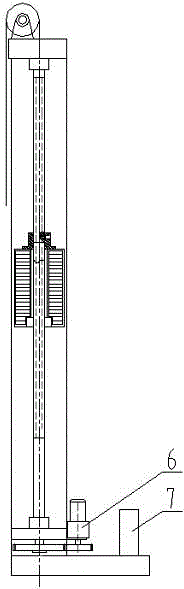

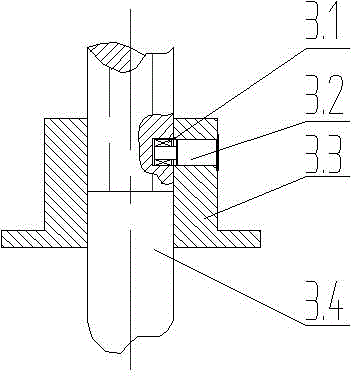

[0019] combined with figure 1 and 2 , the reciprocating screw reversing pumping unit mentioned in the present invention includes a base assembly 1, a frame assembly 2, a reversing mechanism assembly 3, a counterweight box assembly 4, a wire rope assembly 5, and a motor reducer assembly 6. The electric control cabinet assembly 7, the rack assembly 2 is installed on the base assembly 1, the reversing mechanism assembly 3 is installed in the rack assembly 2, and the counterweight box assembly 4 is installed on the reversing mechanism Between the assembly 3 and the frame assembly 2, the wire rope assembly 5 bypasses the top pulley of the frame and is installed between the counterweight box assembly 4 and the sucker rod column, the motor reducer assembly 6 and the electric control cabinet assembly 7 Installed on the base assembly 1, the motor reducer assembly 6 drives the reciprocating screw rod through the gear pair, and the motor reducer assembly 6 is equipped with a normally cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com