Soundless rock drilling and splitting integrated machine

An all-in-one machine and rock technology, applied in reciprocating drilling rigs, drilling equipment, discharge machinery, etc., can solve problems such as high noise, affecting operating efficiency, and shortening the service life of splitting blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

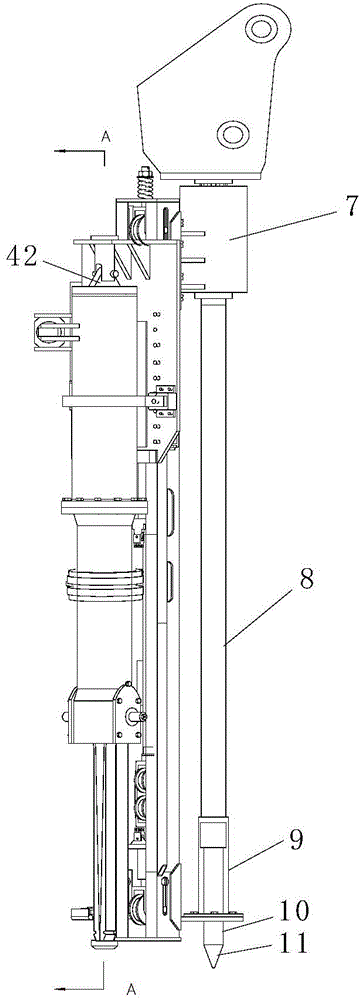

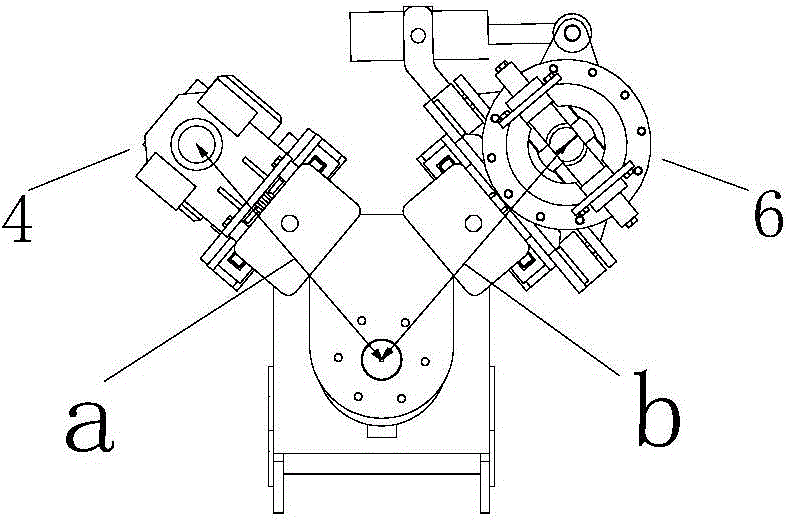

[0025] refer to figure 1 — Figure 5, this embodiment includes an articulation head 1, a rock drilling slide rail 2, a splitting slide rail 3, a rock drill 4 slidably arranged in the rock drilling slide rail, a sliding seat 5 slidably arranged in the splitting slide rail, The splitter 6 is fixed on the sliding seat, and also includes a rotating part that is rotatably suspended on the hinged head. The rock drilling slide rail 2 and the splitting slide rail 3 are fixedly connected with the rotating part. The centerline of the drill bit of the rock drill 4 is The distance a between the center axis of the rotating part is equal to the distance b between the center line of the splitter and the center axis of the rotating part. The rotating part is a rotating oil cylinder 7 . The lower part of the rotating device is provided with a support column 8, the upper end of the support column is connected with the cylinder shaft of the rotary oil cylinder 7, the lower end of the support c...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, the difference is that the rotating part is driven by a rotating motor 37, the rotating motor 37 is fixed on the joint 1, the output shaft of the rotating motor 37 is connected with the input shaft of the rotating part, and the rotating part is a rotating Barrel 39. Said splitting oil cylinder 14 is hung on the sliding seat top plate and the flexible hanging parts are soft wire ropes 38, available soft copper wire ropes. The rotation of splitting oil cylinder 14 cylinders adopts steering hydraulic rotary motor 43 to drive, and on the sliding seat, a steering hydraulic rotary motor 44 is fixed, and the rotating shaft of adopting steering hydraulic rotary motor 43 drives splitting oil cylinder 14 cylinders to rotate.

[0031] During operation, the rotating cylinder 39 is driven by the rotating motor 37 to rotate the slide rail assembly, driving the rock drilling slide rail 2 and the splitting slide rail 3 to rotate, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com