Integrated structure of concrete tower drum and foundation of fan

A technology of concrete and reinforced concrete, which is applied in infrastructure engineering, wind turbines, wind turbine components, etc., and can solve problems such as waste, large volume of foundation ring, and high cost of foundation ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

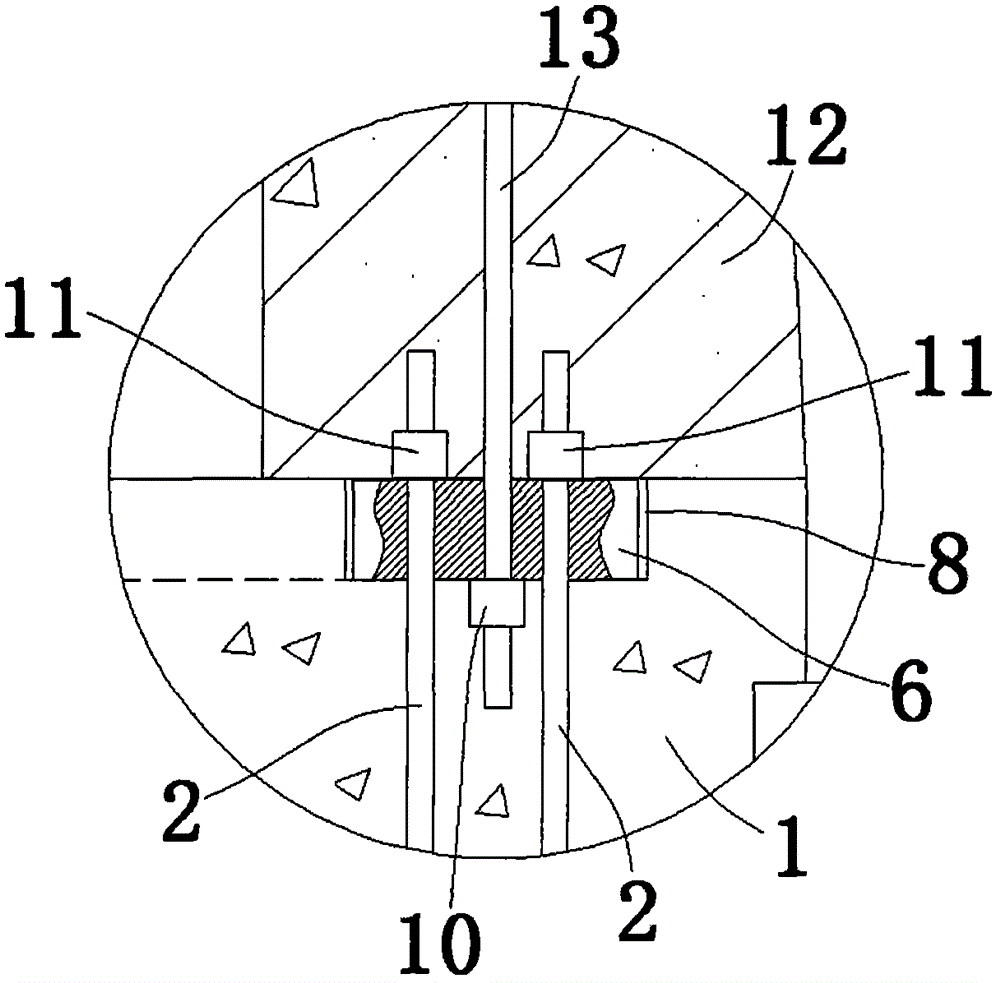

[0032] Such as figure 1 , 2 As shown, the reinforced concrete column 1 is embedded with first high-strength bolts that are evenly distributed on two concentric circles and are parallel to each other, forming a large circle and a small circle. The lower ends of the first high-strength bolts pass through the buried The bottom flange 3 at the bottom of the reinforced concrete column 1 is screwed to the first nut 5, and the bottom flange 3 is horizontally arranged in the reinforced concrete column 1, such as Figure 5A As shown, the bottom flange 3 is provided with first through holes 4 matched with the first high-strength bolts, and the first through holes 4 are evenly distributed on the bottom flange 3 in two concentric circles. The distribution of the first through holes 4 corresponds to the distribution of the first high-strength bolts; the upper ends of the first high-strength bolts extend vertically upwards, and the first high-strength bolts pass through the reinforced conc...

Embodiment 2

[0038] Except the following structures, other uniform structures are the same as Example 1:

[0039]Such as Figure 3B As shown, the top of the reinforced concrete column 1 corresponding to the position of the intermediate flange 6 is provided with a first groove 8 for embedding the intermediate flange 6, and the depth of the first groove 8 is smaller than that of the The thickness of the middle flange 6, the bottom of the reinforced concrete tower 12 corresponding to the position of the middle flange 6 is provided with a second groove 9 for embedding the middle flange 6, the second groove 9 The depth is smaller than the thickness of the middle flange 6 .

Embodiment 3

[0041] Such as Figure 8 As shown, the reinforced concrete column 1 is embedded with first high-strength bolts uniformly distributed on a concentric circle and parallel to each other, and the lower ends of the first high-strength bolts pass through the bottom embedded in the bottom of the reinforced concrete column 1 Flange 3 and threaded first nut 5, such as Figure 5B As shown, the first through holes 4 are provided on the bottom flange 3, and the first through holes 4 are evenly distributed in a circle.

[0042] The reinforced concrete tower 12 is embedded with second high-strength bolts 13 evenly distributed in a circle, and the circle surrounded by the second high-strength bolts 13 is concentric with the circle surrounded by the first high-strength bolts. The radius of the circle surrounded by the second high-strength bolts 13 is smaller than the radius of the circle surrounded by the first high-strength bolts.

[0043] Such as Figure 6B As shown, the intermediate fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com