Cotton loosening knocking device

A technology of knocking rods and sliding rods, which is applied in the direction of fiber opening and cleaning machines, etc., can solve the problems of different cotton knocking effects, complex processing form structure, and uneven fluffy cotton, etc., so as to achieve good knocking effect, easy transmission, and high energy consumption. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

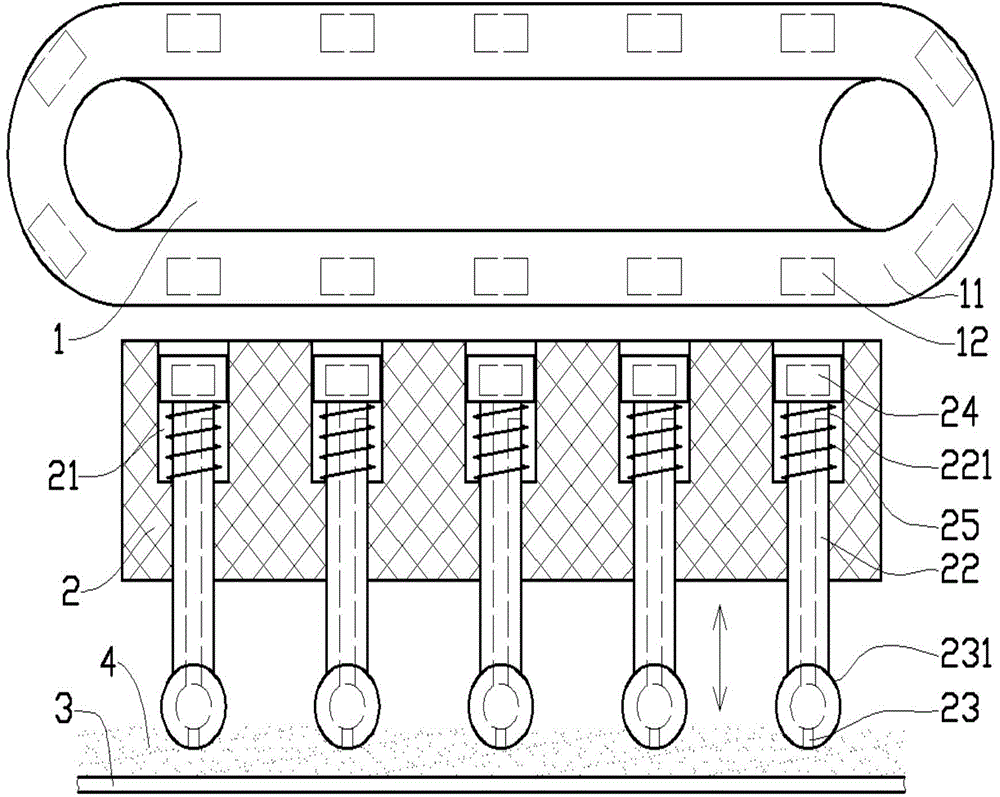

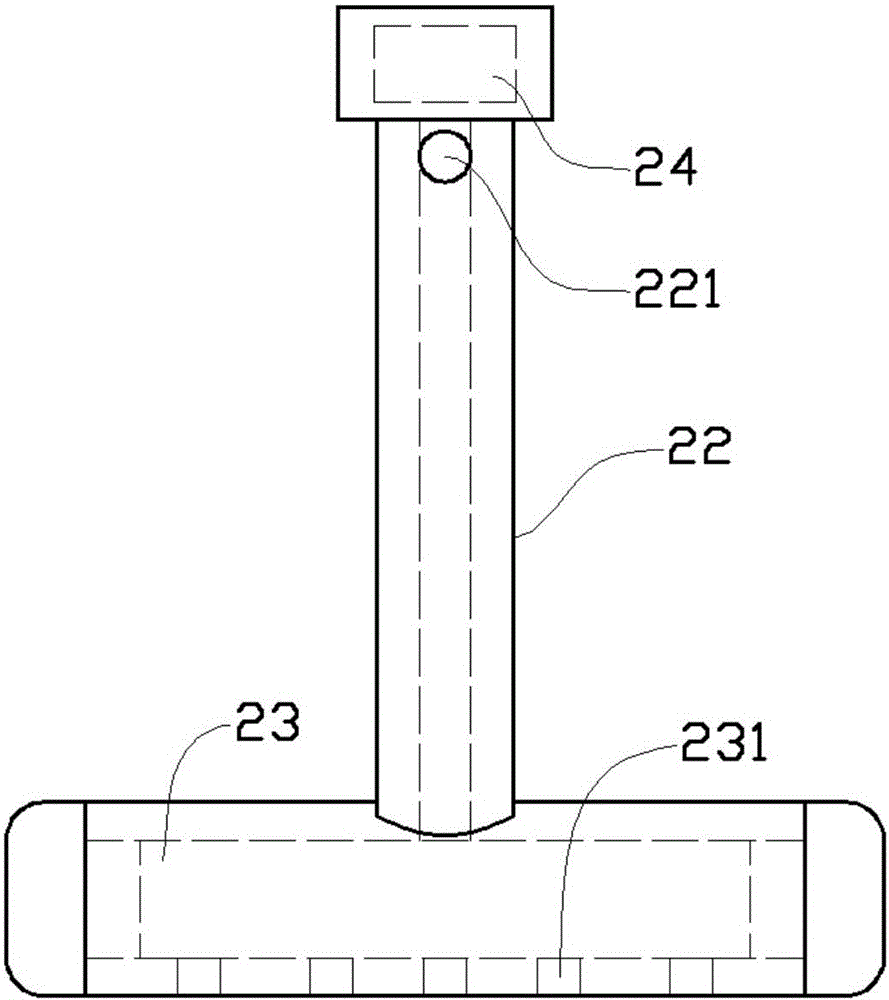

[0013] Such as figure 1 As shown in the embodiment, the cotton opening and knocking device includes a drive module 1, a positioning and knocking module 2, and a delivery module 3; the positioning and knocking module 2 is assembled on the lower part of the driving module 1, and it is characterized in that: The positioning knocking module 2 is processed with more than two positioning holes 21 vertically penetrating in sequence. The positioning holes 21 are equipped with a sliding rod 22 on the knocking module. The lower part of the sliding rod 22 is designed There is a horizontal knocking rod 23, and the upper part of the sliding rod 22 is designed with a lower magnetic block 24 facing the same vertical magnetic pole up and down in the direction of the magnetic force line. The surface of the drive belt 11 is designed with an upper magnetic block 12 with the same ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com