Online utilization method of fluidized bed externally-discharged hydrogenation demetallization catalyst

A hydrodemetallization and catalyst technology, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, can solve the problems of catalytic activity and effective utilization of heat energy that have not been mentioned, so as to reduce the load and improve the economy sex, performance-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

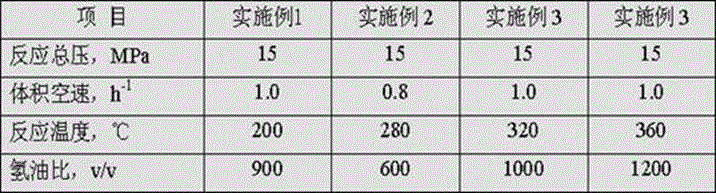

Embodiment 1-4

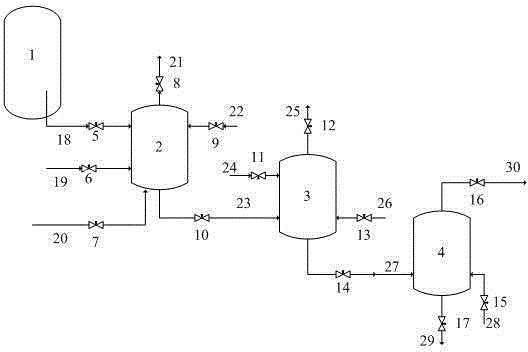

[0036] The ebullating bed reactor 1 is connected with a catalyst discharge tank 2, and the downstream of the catalyst discharge tank 2 is provided with a catalyst buffer tank 3 equal in volume to it, and the catalyst buffer tank 3 communicates with a hydrogenation preprocessor 4 whose volume is 1.5 times its volume. The catalyst discharged from the ebullated bed first enters the prepared catalyst discharge tank filled with 350°C hot distillate oil (distillation range 350-500°C), and the pressure of the catalyst discharge tank is 0.05 MPa lower than that of the ebullated bed reactor. Then close the valve on the catalyst discharge pipeline, the ebullated bed reactor 1 is disconnected from the catalyst discharge tank 2, and then the catalyst in the catalyst discharge tank 2 is discharged into the ready catalyst buffer tank 3, and then the buffer tank 3 All the catalysts in the hydrogenation pretreater 4 are discharged into the hydrogenation pretreater 4, and the mixture of coal ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com