Ceramic mould preparation gypsum powder and preparation method thereof

A technology for ceramic molds and gypsum powder, which is applied in the field of gypsum powder for preparing ceramic molds and its preparation, can solve the problems of poor water absorption, poor coagulation expansion rate, low strength, etc. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

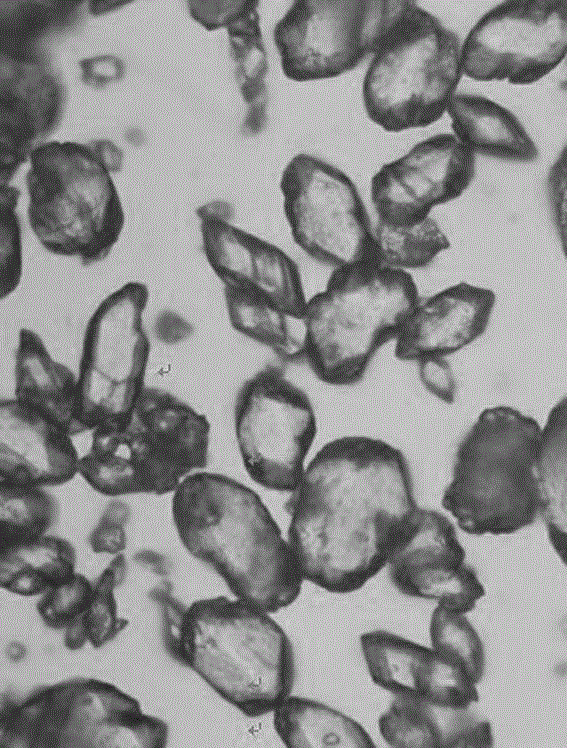

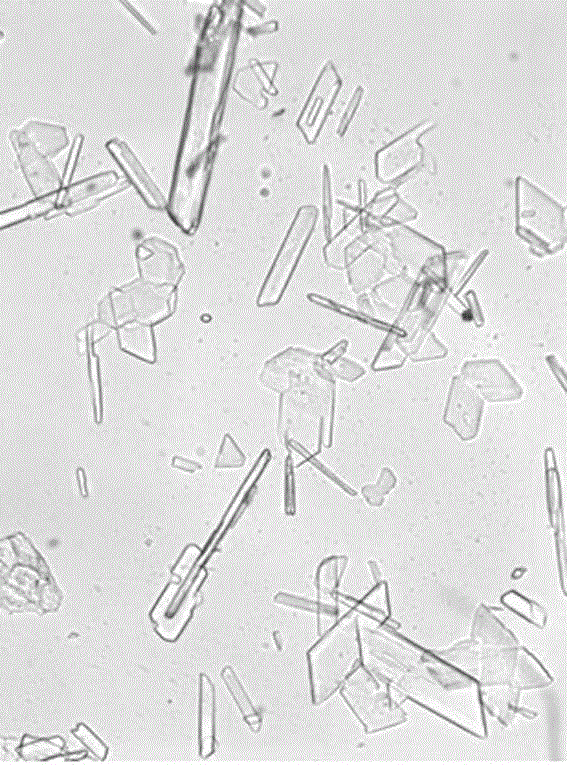

Image

Examples

Embodiment 1

[0022] The desulfurized gypsum and citric acid gypsum were calcined in a fluidized bed calcination system at a ratio of 3.5:1 by weight, and then pulverized by grinding equipment for 10 minutes. By weight, take 98.96 parts of main material powder after grinding, 0.04 parts of sodium citrate, and 1 part of quicklime, put them into a mixer, stir for 25 minutes, and the stirring speed is 58 rpm to obtain 100 parts of ceramic mold gypsum powder.

Embodiment 2

[0024] The desulfurized gypsum and citric acid gypsum were calcined in a fluidized bed calcination system at a ratio of 4:1 by weight, and then ground for 25 minutes with a grinding equipment. By weight, take 98.98 parts of ground gypsum powder, 0.02 parts of citric acid, and 1 part of calcium sulfate whisker, and put them into a mixer, stirring for 30 minutes at a stirring speed of 60 rpm to obtain 100 parts of ceramic mold gypsum powder.

Embodiment 3

[0026] The desulfurized gypsum and citrate gypsum were calcined in a fluidized bed calcination system at a weight percentage of 4.5:1, and then ground for 15 minutes with a grinding equipment. By weight, take 98.95 parts of ground gypsum powder, 0.05 parts of citric acid, and 1 part of quicklime, put them into a mixer, stir for 35 minutes, and the stirring speed is 62 rpm to obtain 100 parts of ceramic mold gypsum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com