telescopic conveyor

A technology of conveyor and telescopic section, applied in the field of automation equipment, can solve the problems of unstable telescopic, unreasonable transmission mechanism setting, short transportation and transportation time, etc., and achieve the effect of stable telescopic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

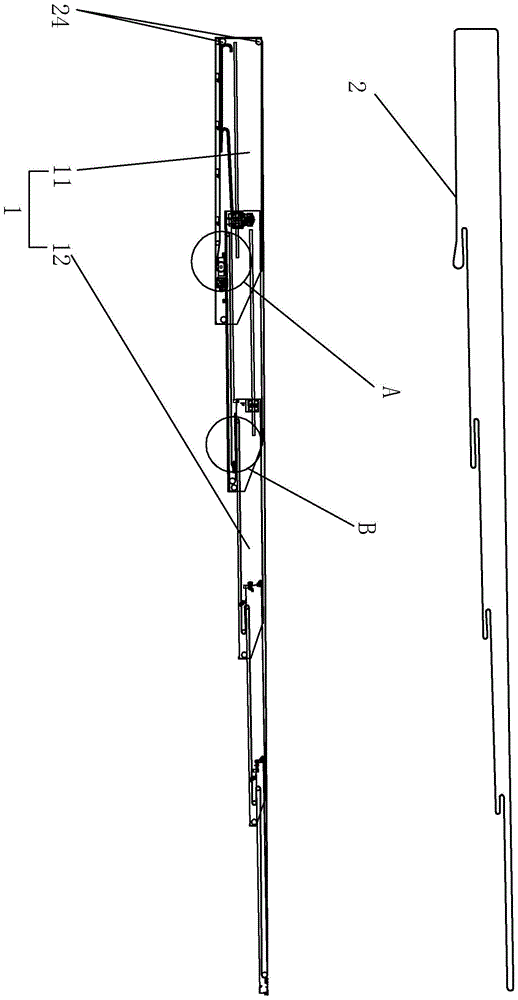

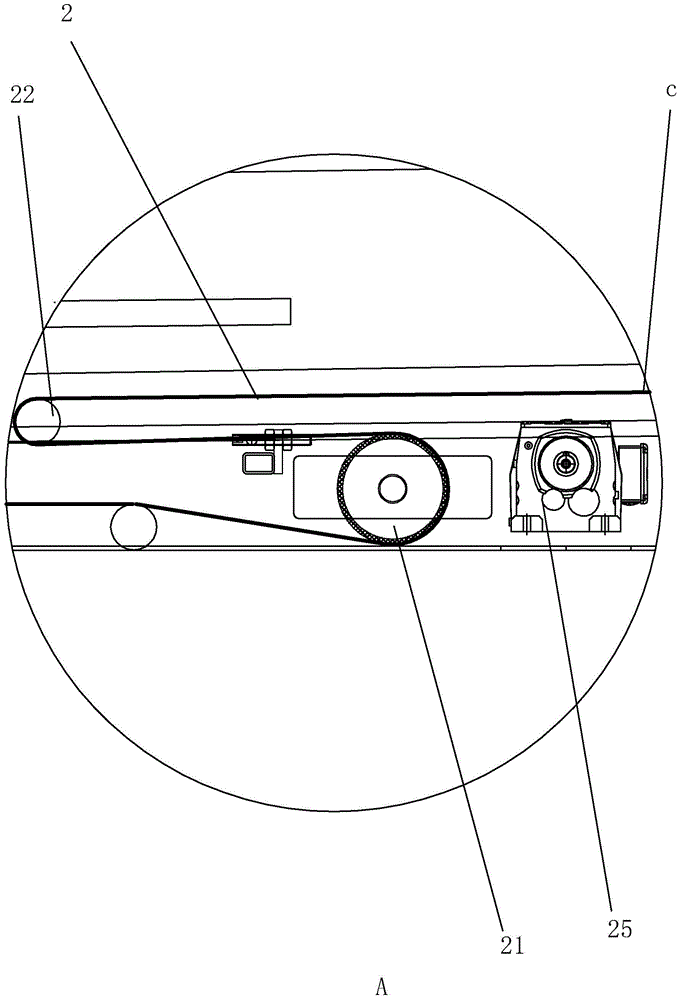

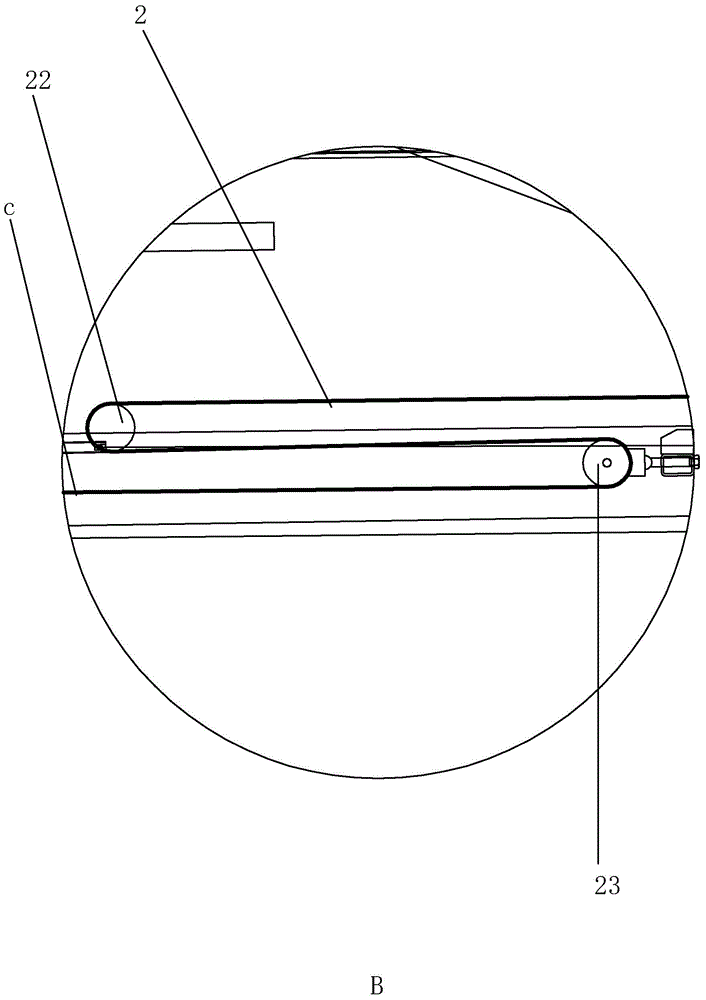

[0033] The telescopic conveyor embodiment of the present invention will be further described with reference to the accompanying drawings.

[0034] A telescopic conveyor, including a frame 7, a driving device and a multi-section transmission device 1. The following embodiments all take a five-section transmission device 1 as an example. The transmission devices 1 are sleeved and connected in turn, and the outermost transmission device 1 is the main section for conveying The device 11 is also connected with the frame 7, the inner side is the telescopic section transmission device 12, the side of the main section conveying device 11 is connected with the electric control box 8, the driving device makes the telescopic section transmission device 12 realize expansion and contraction through the chain transmission, and the telescopic section transmission device 12 One end is the protruding end, and the other end is the tail end. Such a setting makes the telescopic conveyor more flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com