Filter element and its preparation method and application

A filter element and carrier technology, applied in the field of particle filtration in gas, can solve the problems of the adhesive graphene coating falling off, the graphene coating falling off easily, the user's breathing difficulty, etc., to reduce the filtration burden, Soft and strong, beautiful appearance style, smooth breathing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

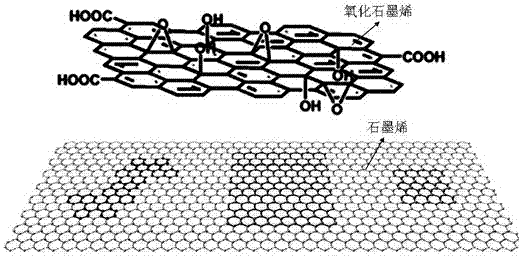

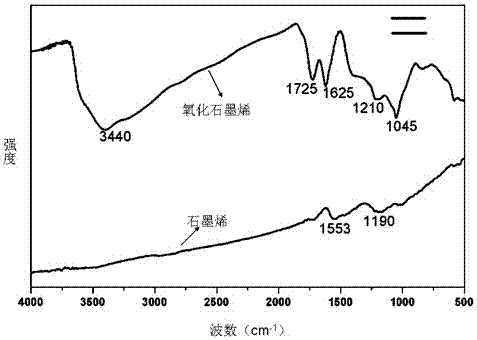

[0037] Step 1, weighing 2 mg of graphite oxide, and dispersing it in 98 mg of water, ultrasonically dispersing to form a graphene oxide gel with a mass fraction of 2%;

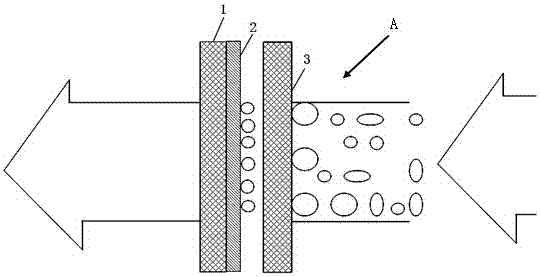

[0038] In step 2, the non-woven fabric is washed with ethanol and water successively and dried. On the air-permeable carrier (the air-permeable carrier in this embodiment is non-woven fabric) 1, the graphene oxide gel is coated on the air-permeable carrier 1 by the method of doctor blade coating.

[0039] Step 3, drying to obtain a graphene oxide layer 2 with a thickness of 100 nm;

[0040]Step 4, the air-permeable layer 3 (the air-permeable layer in this embodiment is a non-woven fabric) is attached to the graphene oxide layer 2, and the air-permeable carrier 1, the graphene oxide layer 2 and the air-permeable layer are bonded by ultrasonic bonding. 3. Carry out sideline pressing to become one.

Embodiment 2

[0042] The preparation method is basically the same as in Example 1, except that the mass fraction of graphene oxide is 0.9%, and the method of screen printing is used to form a 1nm thick film on the air-permeable carrier (the air-permeable carrier in this embodiment is gauze) 1. graphene oxide film.

Embodiment 3

[0044] The preparation method is basically the same as in Example 1, except that the mass fraction of graphene oxide is 5%, and the method of brushing is used to obtain a thickness of 500um on the air-permeable carrier (the air-permeable carrier in this embodiment is a non-woven fabric) 1. graphene oxide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com