A suture cutting assembly steering mechanism for surgical staplers

A technique of surgical suturing and steering mechanism, applied in the direction of surgical fixation nails, etc., can solve the problems of long unfavorable recovery time for patients, large incisions for surgical patients, inconvenient operation by doctors, etc., and achieves the effects of compact structure, easy hand feeling, firm and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

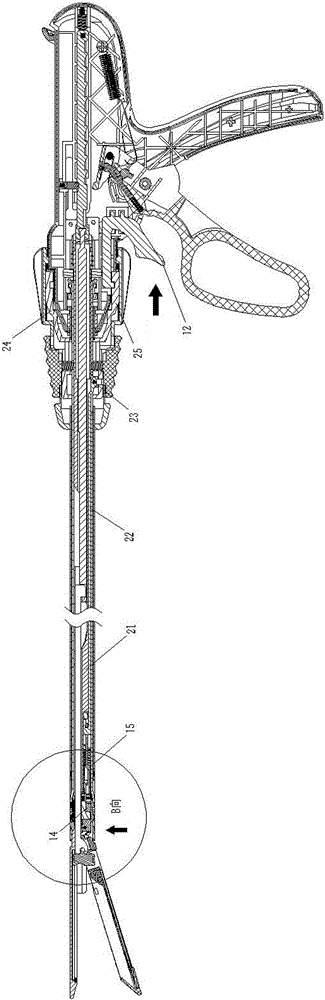

[0044] Refer to attached Figure 1-18 , a sewing and cutting assembly steering mechanism for a surgical stapler includes a corner handle 12, an upper angle driving ring 24, a lower angle driving ring 25, a steering hook 22, a steering positioning card 15, a steering positioning card compression spring 16, and a support seat 17 , Steering support bar 18, steering support bar clip spring 19, steering head 14, blade holder 20 and positioning guide support tube 21.

[0045]The corner handle 12 can be configured as a slide button or a button structure. The corner handle 12 is installed in the corner handle installation sliding groove 10-1 at the front bottom of the fixed handle 10 through the corner handle positioning boss 12-2. Upper angle driving ring 24 and lower angle driving ring 25 are set on the front end of fixed handle 10, and the corner handle cam 12-1 at the front end of corner handle 12 is installed on the corner handle cam mounting groove 25 of the upper angle driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com