Horizontal stuffing feeding machine

A stuffing machine, horizontal technology, applied in the field of horizontal stuffing machine, can solve the problems of nutrient loss, affecting the taste, too broken stuffing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

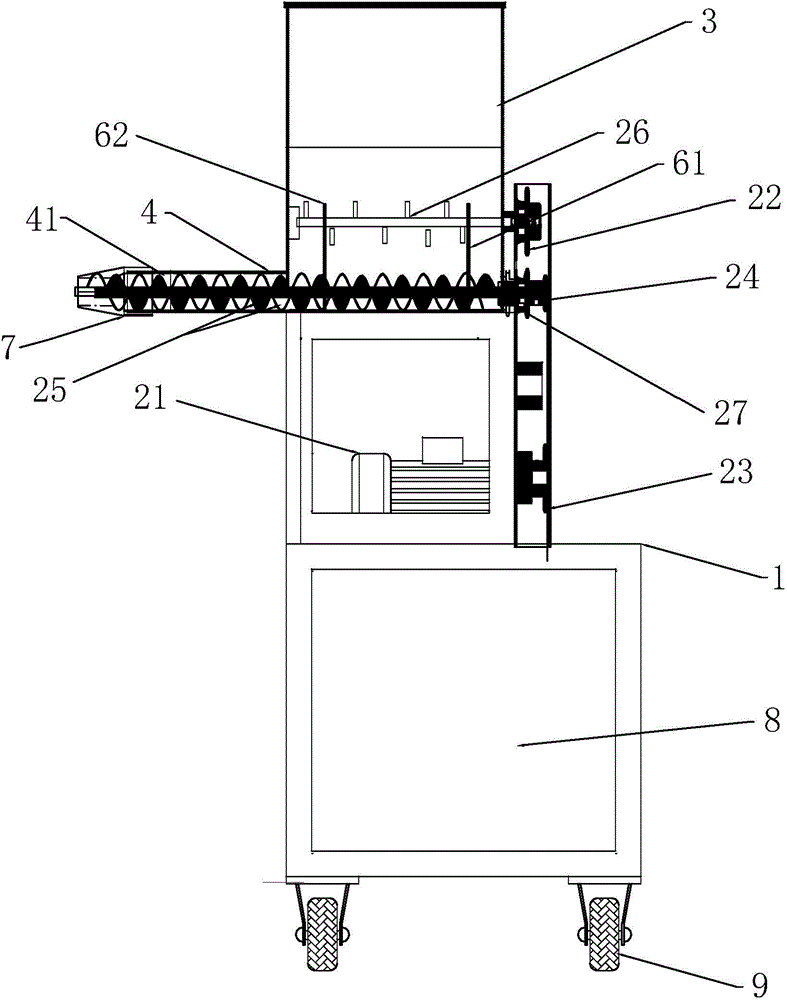

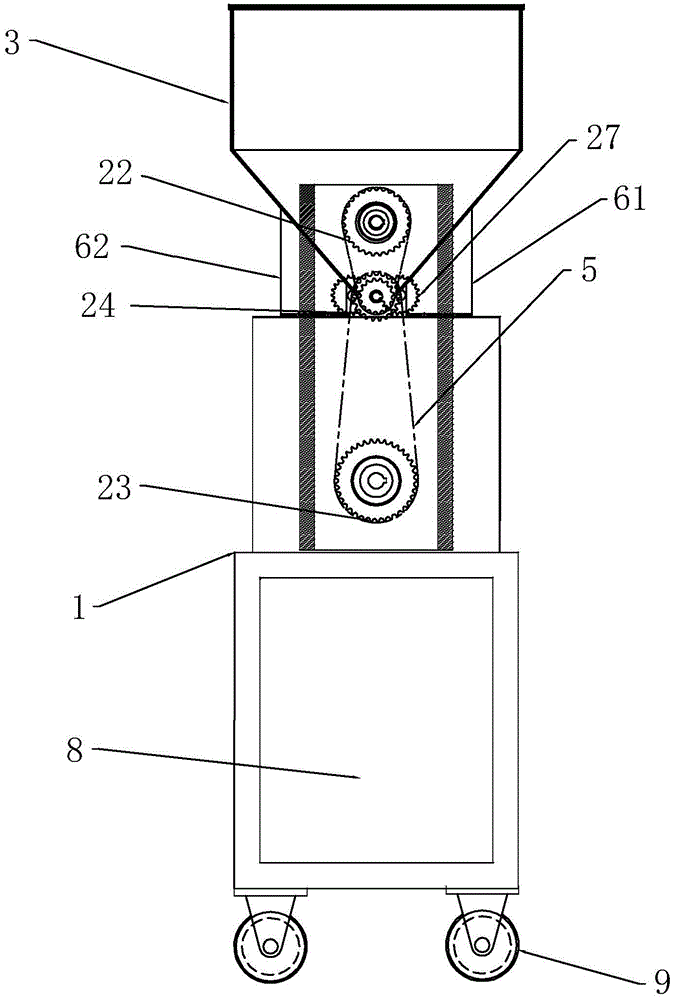

[0021] Such as figure 1 and figure 2 As shown, a horizontal stuffing machine includes a frame 1, a drive system, a barrel 3 and a stuffing barrel 4 that is provided with a filling opening 41; the driving device includes a motor 21, a sprocket 22, a sprocket Two 23, sprocket three 24, two screw rods 25, two gears 27 and a stirring device 26; the motor 21 is seated on the frame 1, and the barrel 3 is located above the motor 21; The second sprocket 23 is arranged on the top of the frame 1 and on one side of the motor 21, and is horizontally and axially connected with the motor 21, and the first sprocket 22 and the third sprocket 24 are arranged on the sprocket Above the second 23, and respectively connected with the second sprocket 23 by the chain 5, the second half of the two screw rods 25 are horizontally arranged at the bottom of the inner cavity of the barrel 3, and are located at the end of the barrel 3. The two gears 27 engaged with the sprocket three 24 on one side are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com