Method for determining the position of an electric motor in a clutch actuation system of a motor vehicle

A clutch control and motor technology, applied in the direction of clutch, motor control, electronic commutation motor control, etc., can solve the problems of no correlation between increment and motor, motor can not be positioned arbitrarily, sensor signal resolution is limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

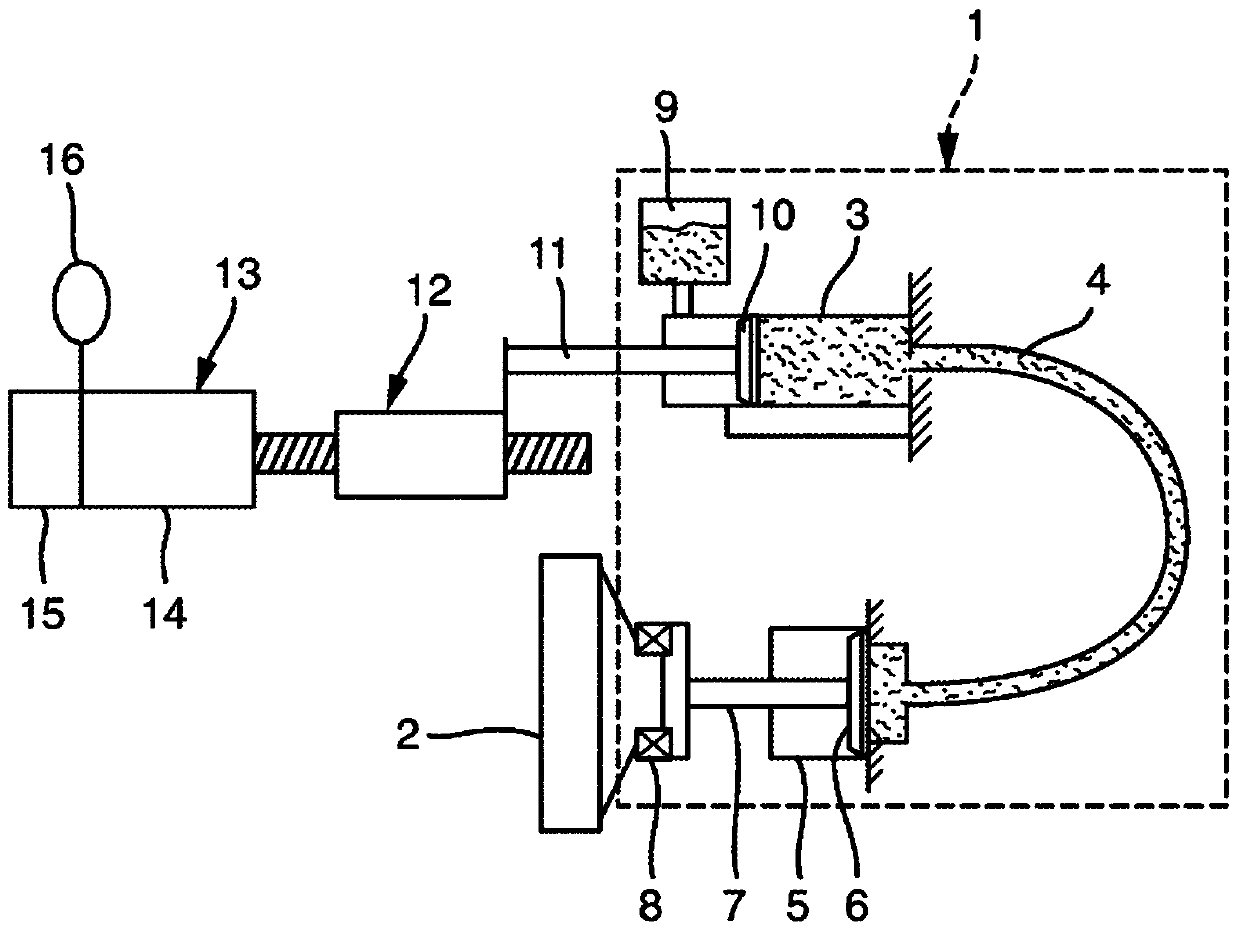

[0022] exist figure 1 A clutch actuation system 1 for an automated clutch is shown in simplified form in . A clutch actuation system 1 is associated with a friction clutch 2 in the drive train of a motor vehicle and comprises a master cylinder 3 which is connected to a slave cylinder 5 via a hydraulic line 4 , also referred to as a pressure line. In the slave cylinder 5 , a slave piston 6 is movable to and fro, which actuates the friction clutch 2 via the actuating mechanism 7 and with the insertion of the bearing 8 .

[0023] The master cylinder 3 can be connected to a compensating container 9 via a connection opening. The master piston 10 is movable in the master cylinder 3 . Starting from the main piston 10 , a piston rod 11 is movable in translation along the longitudinal extension of the master cylinder 3 together with the main piston 10 . The piston rod 11 of the master cylinder 3 is coupled via a spindle 12 to an electric actuating drive 13 . Electric actuating driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com