Method for preparing polypyrrole/sliver nano composite material

A composite material and silver nanotechnology, which is applied in the direction of nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of uneven dispersion of conductive metal silver, and achieve improved conductivity, good tailoring effect, and specific electric capacity. The effect of capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 0.2123g of silver nitrate and 1.005ml of pyrrole monomer were dissolved in 200ml of deionized water to form a uniform mixed system, and 7.5ml of trisodium citrate aqueous solution with a concentration of 0.5mol / L was added therein at a rate of 3mL / min under continuous stirring. Continue to stir for 20 minutes after the dropwise addition, then add 50ml of ferric chloride aqueous solution with a concentration of 0.3mol / L at a rate of 10mL / min, and control the temperature at 0°C for 6 hours of reaction. After the reaction, the resulting reaction solution is suction filtered. The obtained filter cake was washed three times with ethanol and deionized water successively, and then dried at a controlled temperature of 60° C. to obtain a spherical or quasi-spherical polypyrrole / silver nanocomposite;

[0023] The amount of above-mentioned silver nitrate used, pyrrole monomer, trisodium citrate aqueous solution is calculated by molar ratio, i.e. silver nitrate: pyrrole monomer: tri...

Embodiment 1

[0031] The amount of ferric chloride aqueous solution used is calculated by molar ratio, that is, pyrrole monomer: ferric chloride is 1:1.

[0032] The polypyrrole particles obtained above were scanned by a Quanta 200FEG environmental scanning electron microscope from FEI Company of the Netherlands, and the obtained SEM image is as follows: Figure 4 As shown, the polypyrrole particles are stacked as chains, and the polypyrrole particles synthesized by the in-situ polymerization method have no regular morphology.

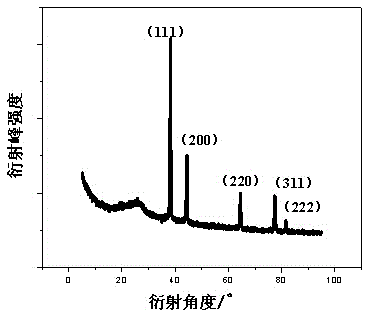

[0033] Will figure 1 and Figure 4 By contrast, it can be seen that in the preparation method of a polypyrrole / silver nanocomposite material of the present invention, under the situation that silver nitrate and sodium citrate exist in the preparation process, the particle shape of the gained particles is aggregated by the quasi-spherical chain shape of mutual adhesion. The body became monodisperse spherical particles, which indicated that the presence of silver n...

Embodiment 2

[0039] 0.2123g of silver nitrate and 0.650ml of pyrrole monomer were dissolved in 200ml of deionized water to form a uniform mixed system, and 12.5ml of trisodium citrate aqueous solution with a concentration of 0.3mol / L was added therein at a rate of 5mL / min under continuous stirring. Continue stirring for 20 minutes after the dropwise addition, then add 50ml of ferric chloride aqueous solution with a concentration of 0.9mol / L at a rate of 5mL / min, and control the temperature at 5°C for 4 hours of reaction. After the reaction, the resulting reaction solution is suction filtered. The obtained filter cake was washed three times with ethanol and deionized water successively, and then dried at a controlled temperature of 60° C. to obtain a spherical or quasi-spherical polypyrrole / silver nanocomposite;

[0040] The amount of the above-mentioned silver nitrate used, pyrrole monomer, and trisodium citrate aqueous solution is calculated in molar ratio, that is, silver nitrate: pyrrole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com