A new color wheel and color temperature matching method for laser projectors

A technology of laser projector and matching method, which is applied in the direction of using projection device image reproducer, optics, color TV, etc., can solve the problems of unsatisfactory display effect, loss, low efficiency, etc., and achieve good color display effect and color wheel high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment.

[0032] A novel laser projector color wheel and color temperature matching method according to the present invention comprises the following steps,

[0033] (1) First determine the angle corresponding to the fluorescent wheel of the laser light source and the brightness corresponding to the output, G-angle 114 / brightness 2240, Y-angle 190 / brightness 3763, B-angle 56 / brightness 97;

[0034] (2) Select the wavelength band between 490-574nm from the wavelength band of 400-800nm, and its light efficiency is 73.97%;

[0035] (3) Select a wavelength band between 590-700nm from the 400-800nm band, and its light efficiency is 32.89%;

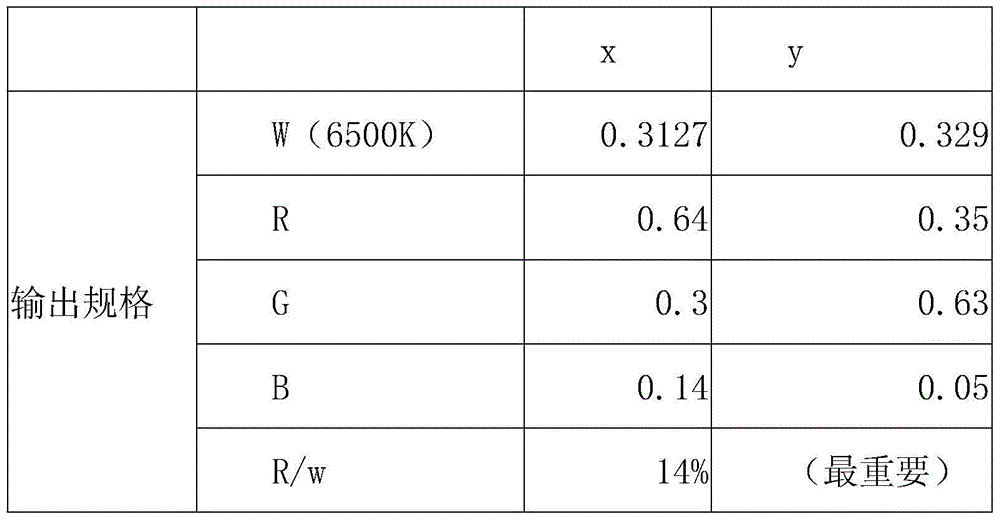

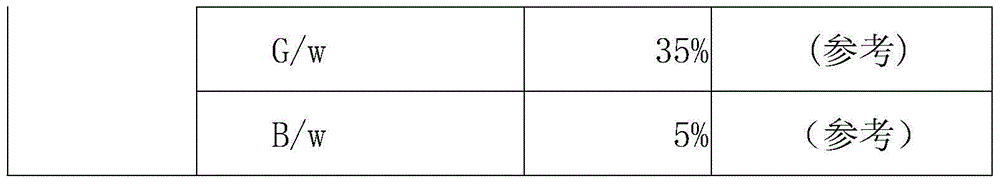

[0036] (4) Select the angle of the red film from the yellow film to ensure that R / W≥14%;

[0037] (5) Calculate the white color coordinates according to the conversion formula of CIE1931 chromaticity coordinates and tristimulus value X.Y.Z;

[0038] (6) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com