Camera lens

A technology of camera lens and lens, applied in the field of camera lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] In Embodiment 1, the camera lens satisfies the conditions of the following table:

[0167] Table 1

[0168]

[0169]

[0170] Table 2

[0171] surface number

A4

A6

A8

A10

A12

S1

-6.1281E-03

4.3661E-03

0.0000E+00

0.0000E+00

0.0000E+00

S2

-1.0340E-02

-2.8693E-03

0.0000E+00

0.0000E+00

0.0000E+00

S3

-1.0662E-01

1.5664E-02

0.0000E+00

0.0000E+00

0.0000E+00

S4

-8.0168E-02

4.9781E-02

0.0000E+00

0.0000E+00

0.0000E+00

S5

-1.2354E-02

1.9507E-02

0.0000E+00

0.0000E+00

0.0000E+00

S6

-1.5146E-02

2.2755E-02

0.0000E+00

0.0000E+00

0.0000E+00

S7

-4.8131E-02

4.9967E-02

0.0000E+00

0.0000E+00

0.0000E+00

S8

-5.6105E-02

1.5113E-02

0.0000E+00

0.0000E+00

0.0000E+00

S9

3.5339E-02

-2.9113E-02

0.0000E+00

0.0000E+00

0.0000E+00 ...

Embodiment 2

[0175] In Embodiment 2, the camera lens satisfies the conditions of the following table:

[0176] table 3

[0177]

[0178] Table 4

[0179]

[0180]

[0181] In addition, TTL=6.06mm; f1=5.25mm; f2=-7.49mm; f3=8.35mm; f4=19.3mm; f5=6.63mm; f6=36.3mm; f7=-3.23mm and f=5mm; Semi- FOV=29.1°; aperture value: 2.2.

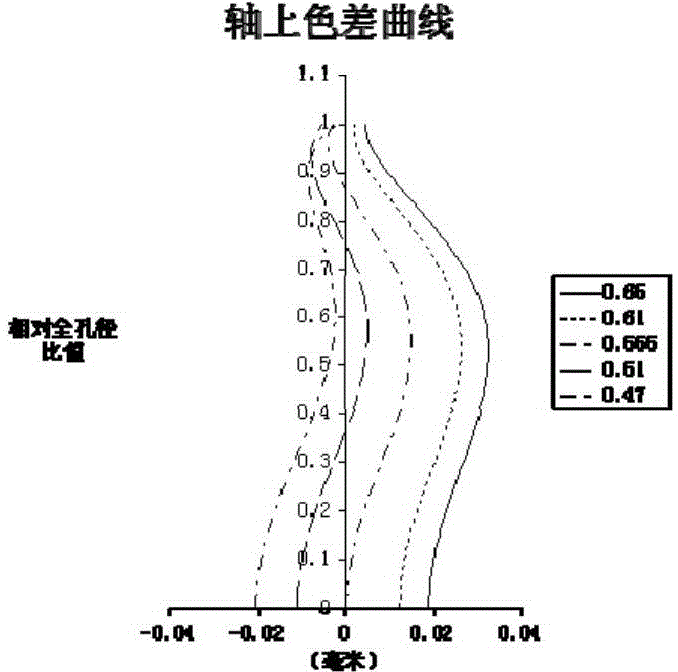

[0182] Figure 7 is the axial chromatic aberration diagram (mm) of the imaging lens of embodiment 2, Figure 8 is the astigmatism diagram (mm) of the imaging lens of embodiment 2, Figure 9 is the distortion figure (%) of the imaging lens of embodiment 2, Figure 10 It is the magnification chromatic aberration diagram (um) of the imaging lens of Embodiment 2. It can be seen that the aberration of the imaging lens is effectively controlled.

Embodiment 3

[0184] In Embodiment 3, the camera lens satisfies the conditions of the following table:

[0185] table 5

[0186]

[0187]

[0188] Table 6

[0189] surface number

A4

A6

A8

A10

A12

S1

4.1137E-03

4.8437E-04

-9.0742E-03

1.7686E-02

-3.1560E-02

S2

-1.7156E-02

-5.0734E-02

-5.8181E-03

-1.5245E-02

8.3683E-03

S3

-6.7316E-02

-1.8944E-02

-3.1239E-02

1.2889E-02

2.0622E-02

S4

-4.6421E-02

2.0324E-02

-5.2405E-03

-1.4123E-02

1.3309E-02

S5

-1.1623E-02

1.1368E-02

1.7479E-02

2.2284E-02

6.3358E-03

S6

-1.0431E-02

-1.3060E-02

2.4245E-02

2.3074E-02

5.9134E-02

S7

-6.7780E-02

-9.0797E-02

5.7161E-02

-1.1590E-01

9.1159E-02

S8

-4.4747E-02

4.3948E-02

-1.8143E-01

9.3766E-02

-1.0675E-02

S9

-1.8909E-02

2.8632E-01

-3.7285E-01

1.4453E-01

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com