Molten salt heating furnace for reaction of catalyst

A heating furnace and catalyst technology, applied in the field of molten salt heating furnaces, can solve the problems of molten salt splashing and hurting people, loss of molten salt, damage to heating elements, etc., and achieve the effects of facilitating the replenishment of molten salt, prolonging service life, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Next, a molten salt heating furnace for catalyst reaction of the present invention will be further described in conjunction with the accompanying drawings and examples.

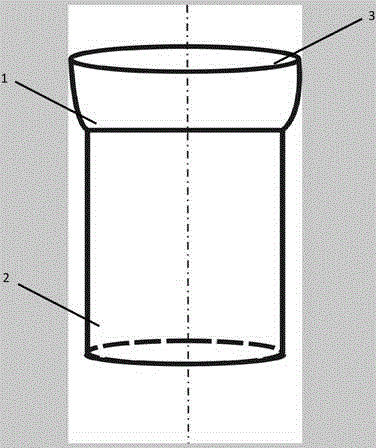

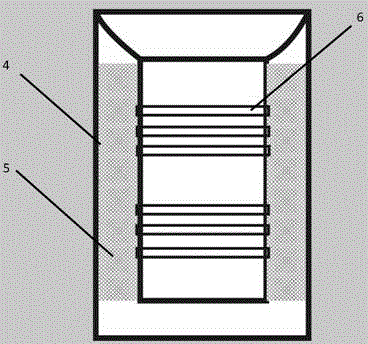

[0015] as attached figure 1 And attached figure 2 As shown, a molten salt heating furnace for catalyst reaction, including a heating module, a heat preservation module and a heating furnace cavity and a shell, is characterized in that: the heating furnace cavity is divided into a cavity main body 2 and a cavity outlet 1 The main body 2 of the inner cavity is cylindrical; the outlet of the inner cavity 1 is an annular arc that is concave to the inside and gradually shrinks from top to bottom, and the bottom of the inner cavity outlet 1 is the same as the inner diameter of the main body 2 The cavity main body 2 is welded and fixed, and the inner diameter of the bottom of the inner cavity outlet is smaller than the inner diameter of the inner cavity outlet top 3; the heating furnace shell 4 is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com