Small crane

A technology of small cranes and booms, which is applied to cranes, clockwork mechanisms, hoisting devices, etc. It can solve the problems of inconvenient installation or maintenance of rollers and motors, easy rope climbing, and severe vibration of heavy objects. Solve the effect of unstable lifting heavy objects, low manufacturing cost, quick installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

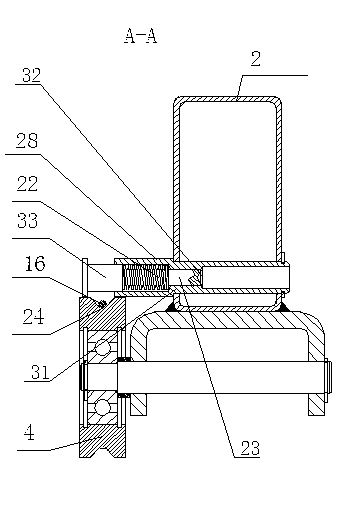

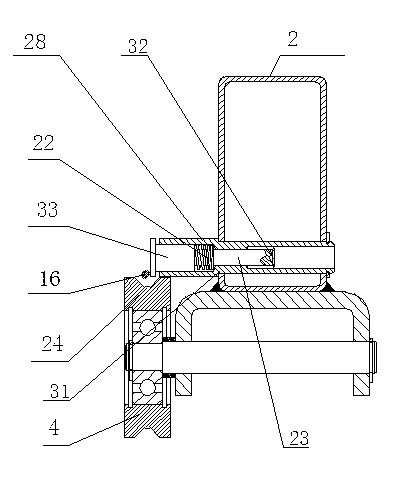

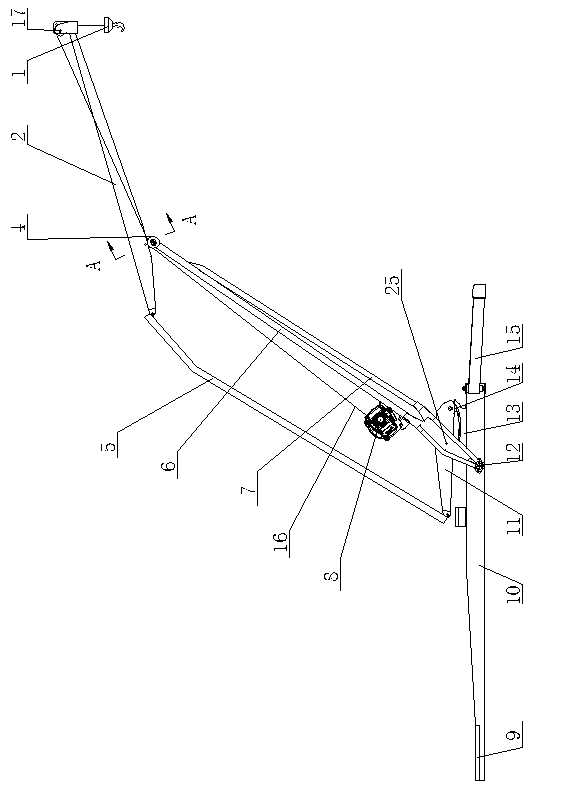

[0009] A kind of small crane described in the present invention comprises base 10, and support arm 6 is installed on base 10, and the lower end of support arm 6 is hinged with base 10 through second hinge shaft 12, and the upper end of support arm 6 is installed boom 2, and the boom The middle part of 2 is hinged with the support arm 6 through the first hinge shaft 3, the rear end of the boom 2 is equipped with a pull arm 5, the top of the pull arm 5 is hinged with the rear end of the boom 2, and the bottom of the support arm 6 is equipped with a lever 11. The middle part of 11 is hinged with support arm 6 by the 3rd hinge shaft 25, and the rear end of lever 11 is hinged with the lower end of pull arm 5, and roller 14 is installed at the front end of lever 11, and guide rail 13 is set on base 10, and the upper surface of guide rail 13 is arc On the surface, the arc surface of the guide rail 13 cooperates with the roller 14; the boom 2, the pull arm 5, the support arm 6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com