Heating tile

A ceramic tile and heating line technology, applied in the field of heating floor, can solve the problems of difficult paving, slow heating of heating floor, easy-to-leave layer, etc., and achieve the effect of easy paving, fast heat conduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. This embodiment only represents one or several best implementation modes, and should not be construed as a limitation to the present invention.

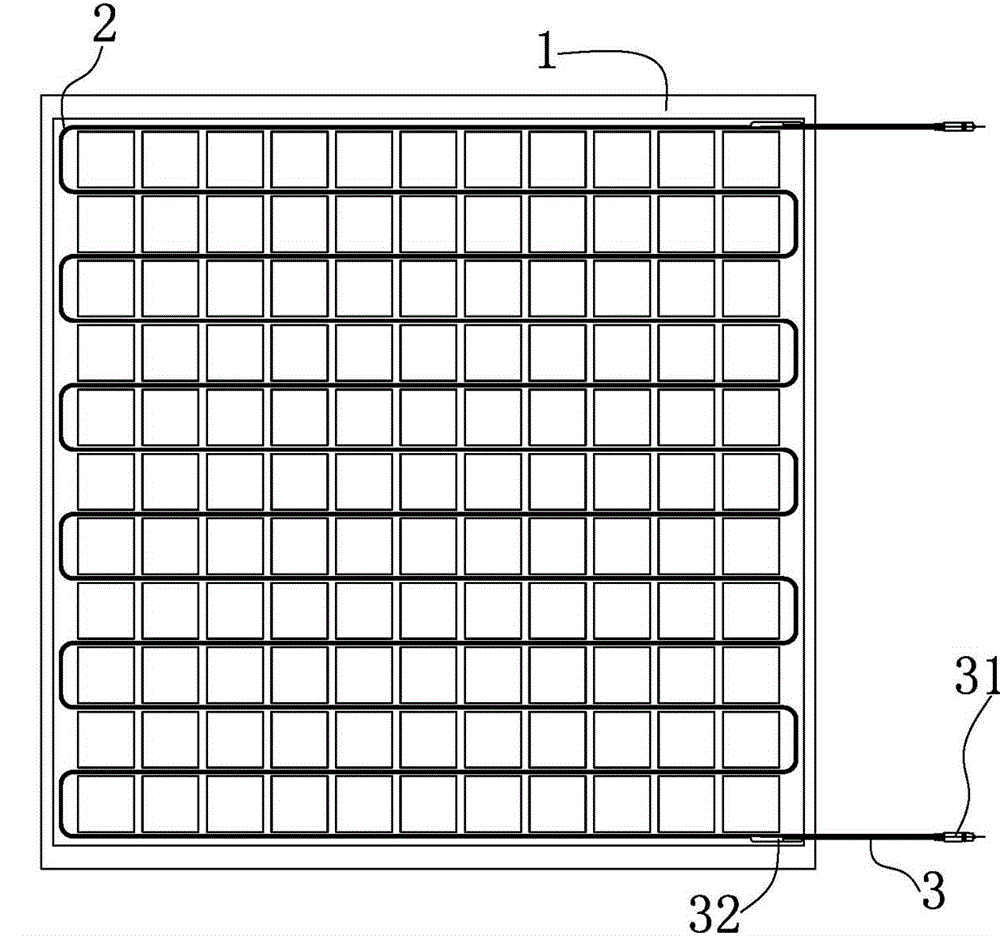

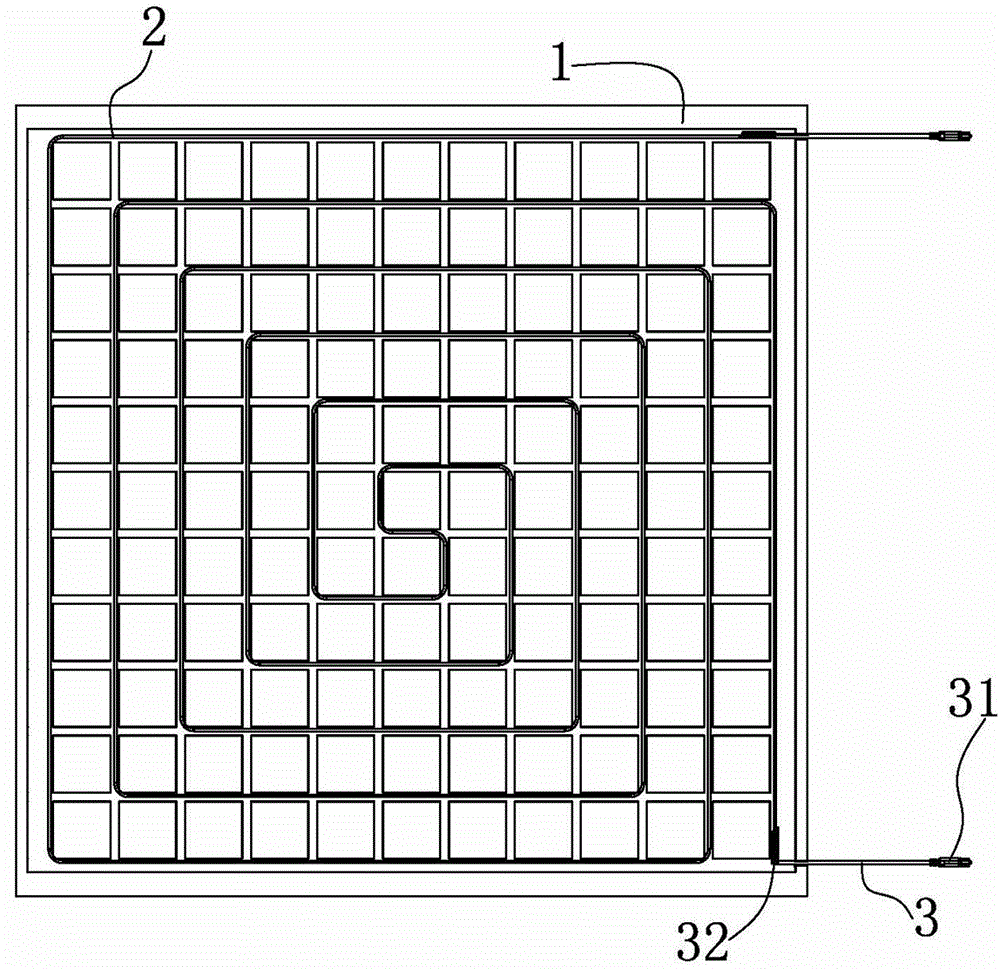

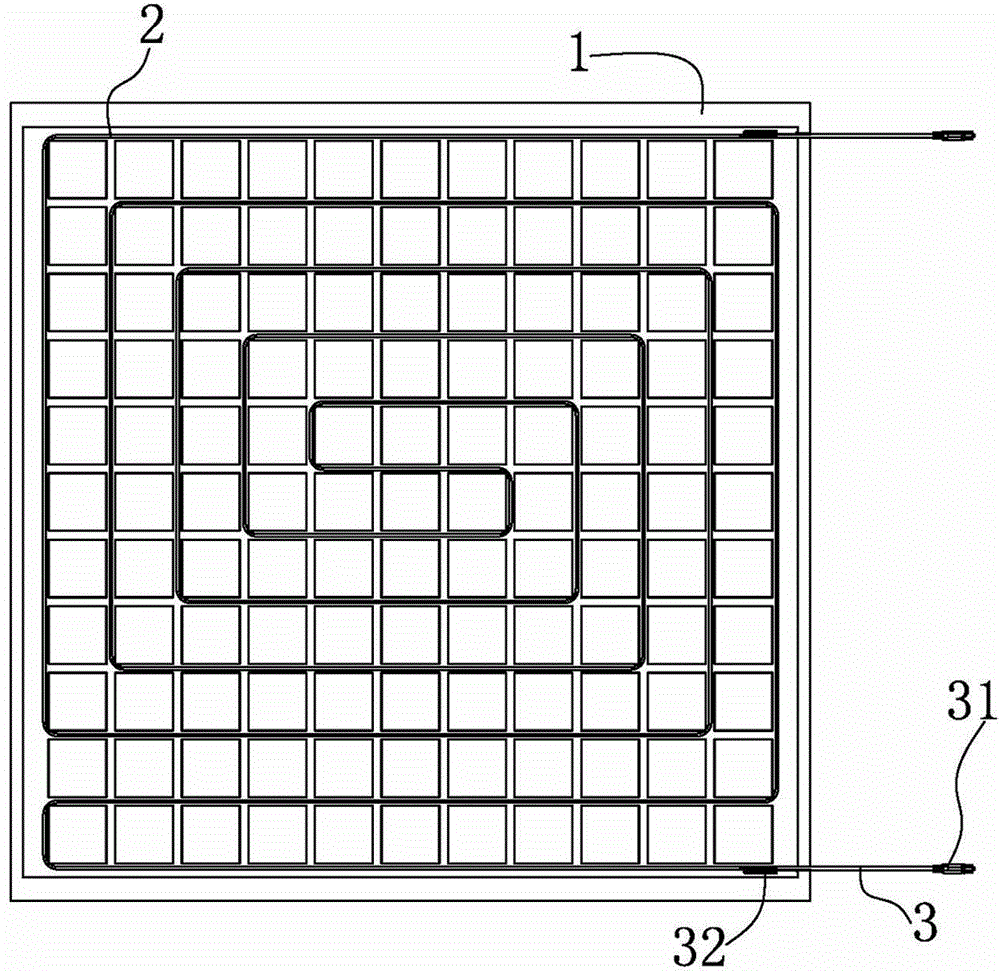

[0026] Such as Figure 1 to Figure 5 As shown, the heating tile provided by the present invention includes a tile 1, a heating wire 2 and a power wire 3, and one side of the tile 1 is provided with a heating wire groove 11, and the heating wire groove 11 is composed of several transverse grooves and longitudinal grooves to form a grid shape structure, the width of each transverse groove and longitudinal groove is 1-5mm.

[0027] The central axis of the heating wire 2 is provided with a conductive wire, and an insulating sleeve is wrapped on the outer side of the conductive wire, wherein the conductive wire is made of copper, nickel, iron, aluminum, chrome alloy or carbon fiber, and the insulating sleeve is made of silica gel, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com