Spring type hydraulic driver for flat gate valve

A technology of hydraulic actuators and flat gate valves, applied in valve details, valve devices, engine components, etc., can solve the problems that the thread cannot be tightened, the anti-rotation effect is limited, and the adverse consequences, etc., to achieve easy adjustment, stable connection, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

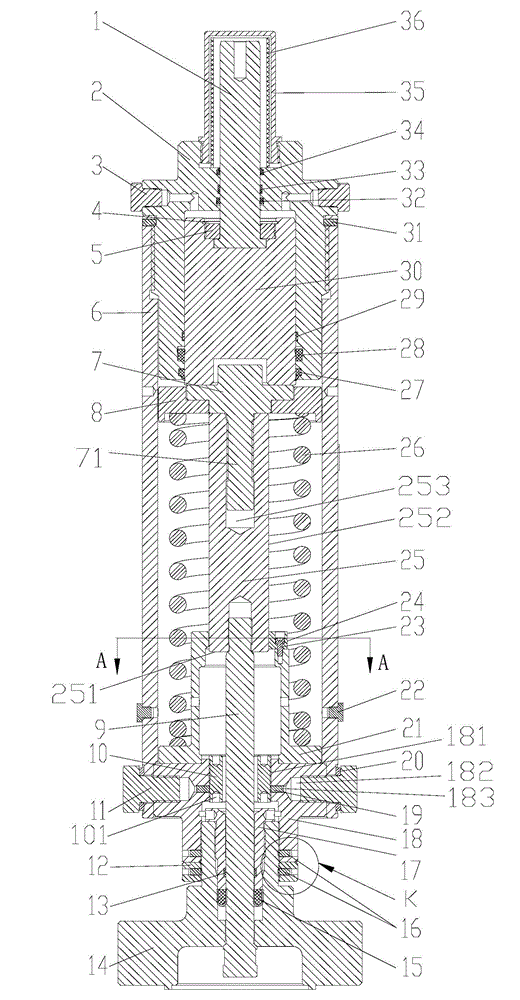

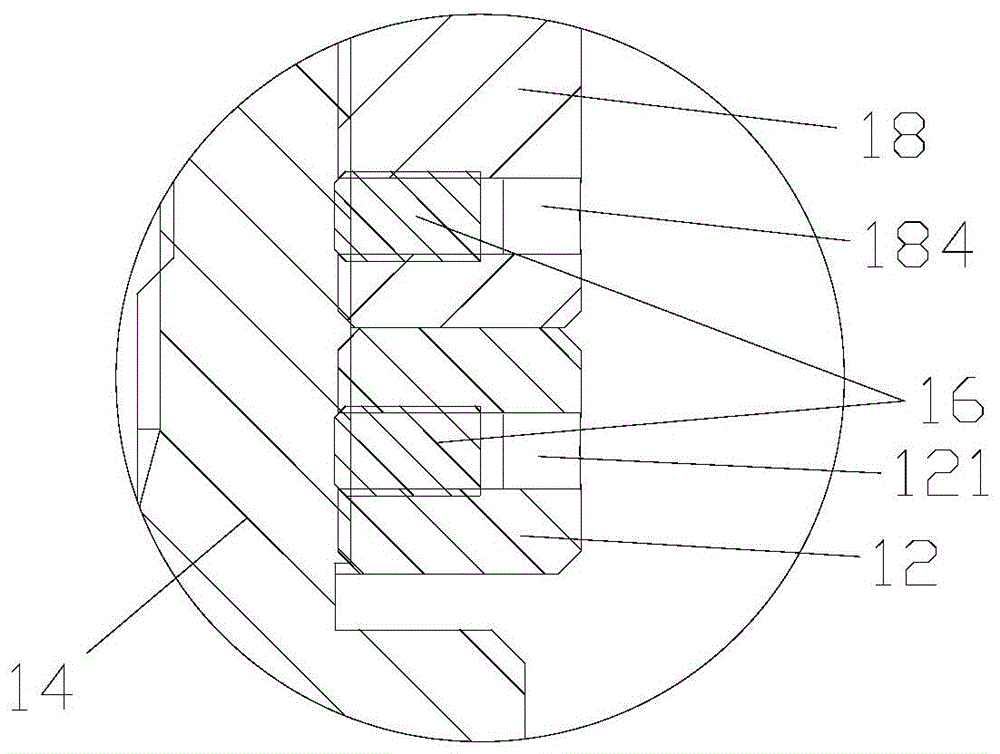

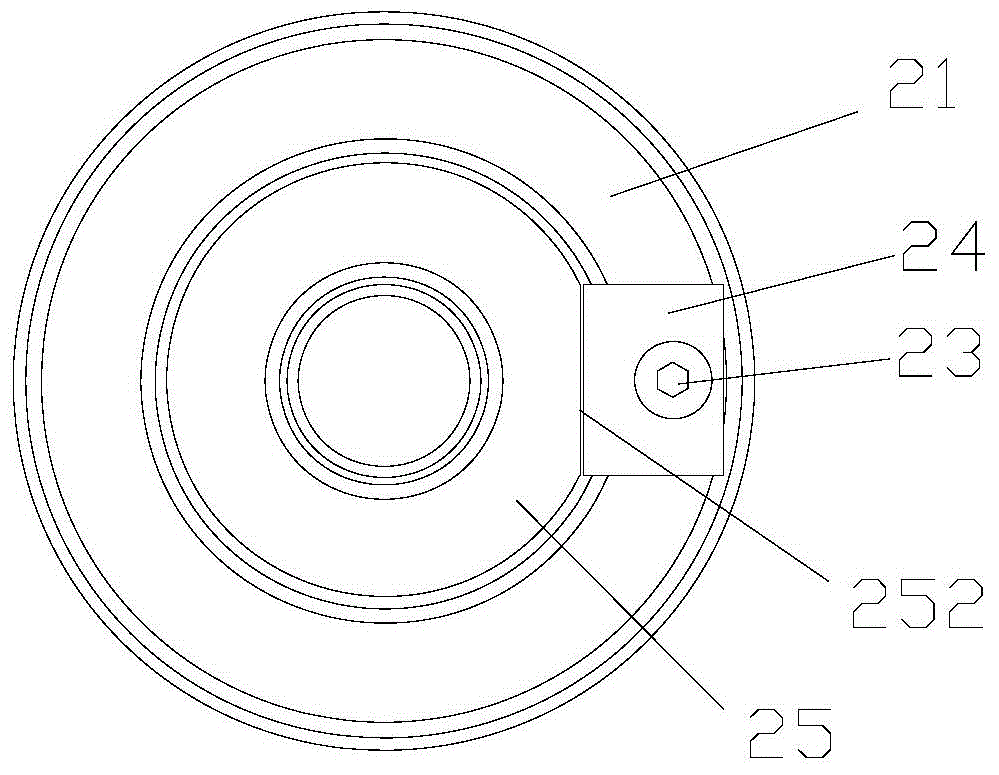

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] see figure 1 , the driver of the present invention does not include the bonnet 14, valve stem 19, packing gland 17, guide belt 13 and packing 15 on the flat gate valve (these parts are classified as valve parts, and the purpose of this design is to reduce the types of drivers, because many times There are differences in the size of the bonnet and valve stem, but the drivers are exactly the same, if it is classified as the driver part, the types of drivers will be increased), figure 1 The purpose of showing these parts in the diagram is to illustrate the installation method, structural features and operation principle of the present invention more clearly and intuitively.

[0032] A spring-type hydraulic driver for a flat gate valve in this embodiment, the main structure includes a driver housing 6 , an upper fixing seat 2 fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com