Planet plate structure of motor rotor

A technology for motor rotors and planetary discs, which is applied to electrical components, electromechanical devices, mechanical equipment, etc., can solve problems such as large resistance, large power consumption, and high fuel consumption of motors, and achieve the effect of reducing transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

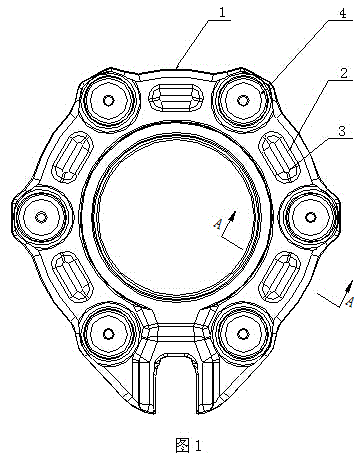

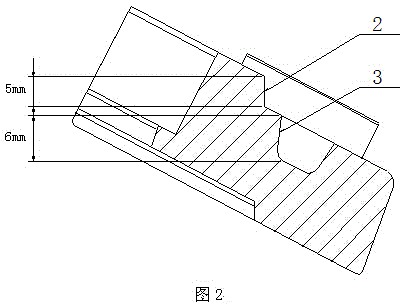

[0012] Such as figure 1 and figure 2 As shown, the present invention includes a planetary disc main body 1, and also includes piston holes 4 evenly distributed on the surface of the planetary disc main body 1. The shape design includes a large waist-shaped groove 2 with a depth of 5 mm, and a small waist-shaped groove 3 located in the large waist-shaped groove 2, and the depth of the small waist-shaped groove 3 is 6 mm. In this embodiment, there are five sets of stepped grooves distributed on the outer circle of the main body 1 of the planetary disk.

[0013] Compared with the existing technology, five sets of stepped grooves are added on the basis of the original planetary disk, which can effectively reduce the cost and reduce the power consumption of the motor while reducing the weight. It can reduce the transmission torque of the internal parts and turn the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com