Vibration absorber

A technology for shock absorbers and automobile shock absorption, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., and can solve problems such as shock absorbers and car bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

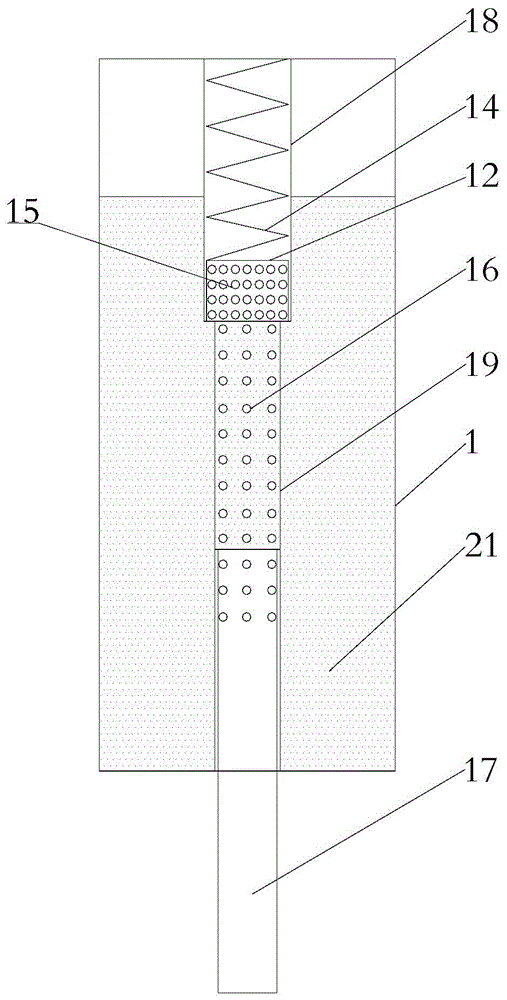

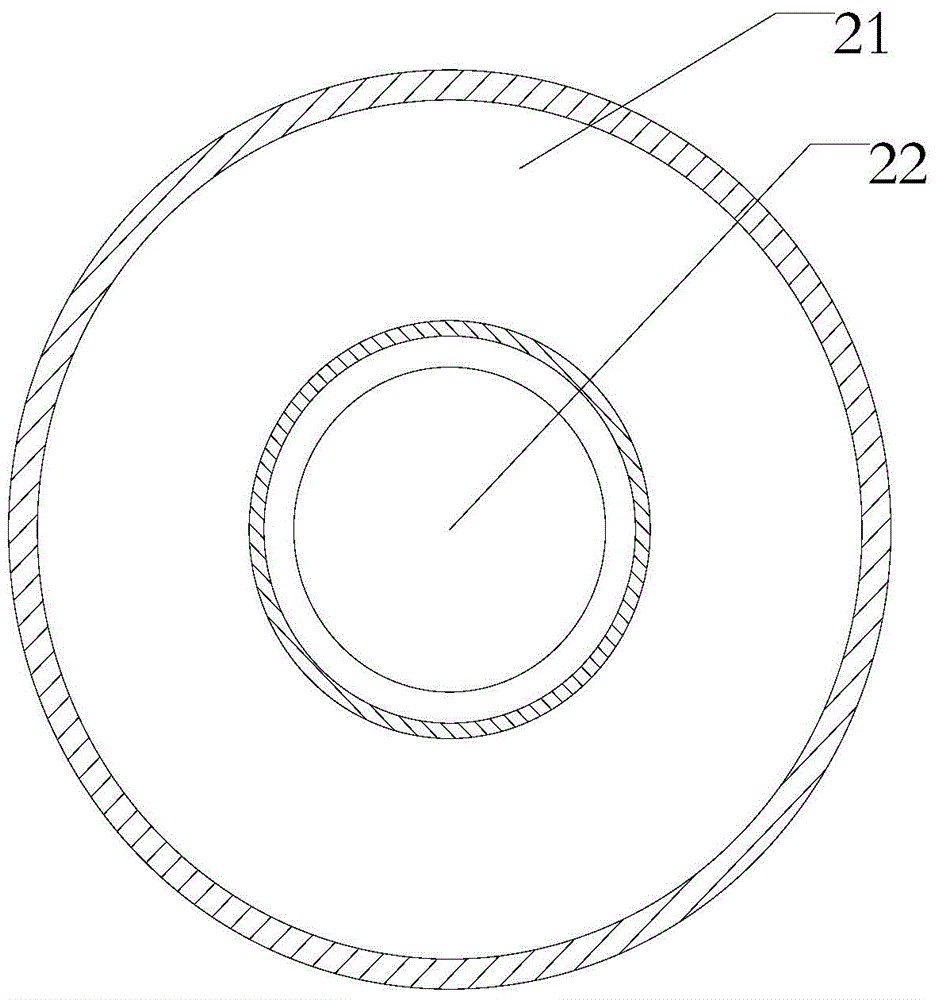

[0064] Such as figure 1 and figure 2 , a shock absorber is provided in an embodiment of the present invention, and the shock absorber includes a vertically arranged master cylinder 1; There is a gap between the cylinders of the layer, forming the main cylinder outer chamber 21; the inner cylinder is hollow, forming the master cylinder inner chamber 22; the cylinder of the inner layer is divided into the first inner cylinder part 18 located above and The second inner cylinder part 19 located below, the outer diameter of the first inner cylinder part is larger than the outer diameter of the second inner cylinder part; wherein:

[0065] The inner cavity of the master cylinder is provided with an active piston rod 17, and the other end of the active piston rod passes through the master cylinder for connection with the wheel;

[0066] A floating piston 12 is arranged above the active piston rod, the floating piston is located in the first inner cylinder, and an auxiliary spring...

Embodiment 2

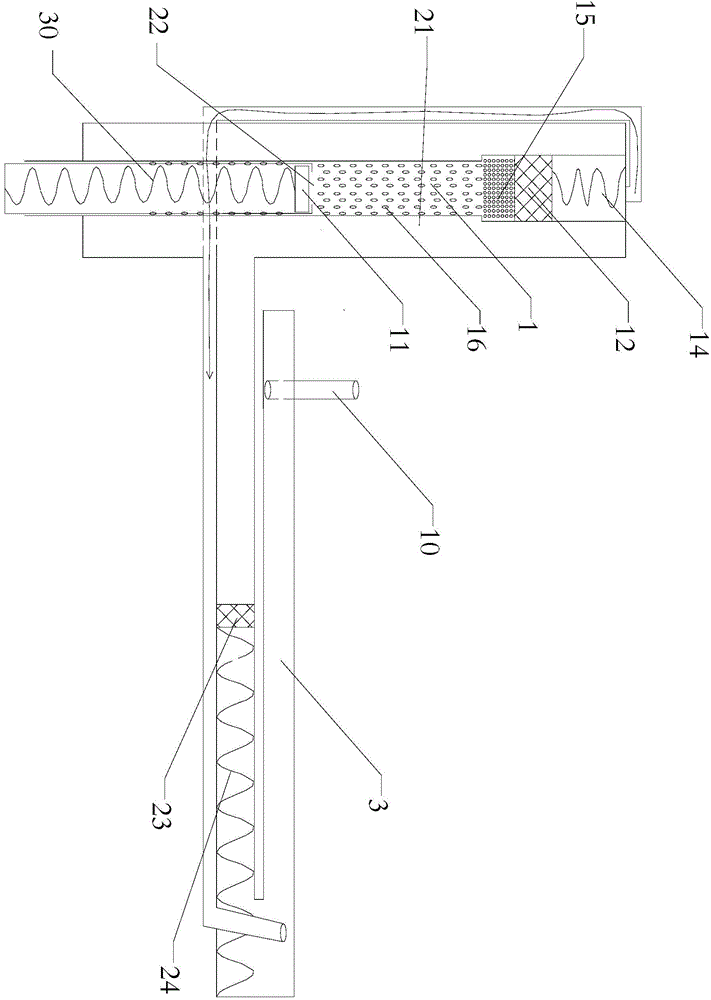

[0071] Embodiment 2 also provides a shock absorber. This embodiment is a further improvement on the basis of Embodiment 1. The technical solution described in Embodiment 1 also belongs to this embodiment. The technical solution described in Embodiment 1 does not Repeat the description again.

[0072] Such as image 3 As shown, a shock absorber is provided in the embodiment of the present invention. The shock absorber also includes an auxiliary cylinder 2 and a normal pressure cylinder 3 communicating with the outside world. The normal pressure cylinder 3 is located in the auxiliary cylinder 2 Above; the cavity between the floating piston 12 and the top of the master cylinder communicates with the normal pressure cylinder, and the outer cavity 21 of the master cylinder communicates with the normal pressure cylinder; the active piston rod is hollow, and its upper end part The opening is provided with a main piston 11 inside, and a main spring 30 is provided between the main pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com