Antistatic weaving bag

A woven bag and antistatic technology, applied in the field of packaging, can solve the problems of inability to meet the needs of use, trouble finding woven bags, etc., and achieve the effect of satisfying the antistatic performance, finding convenience, and stable antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

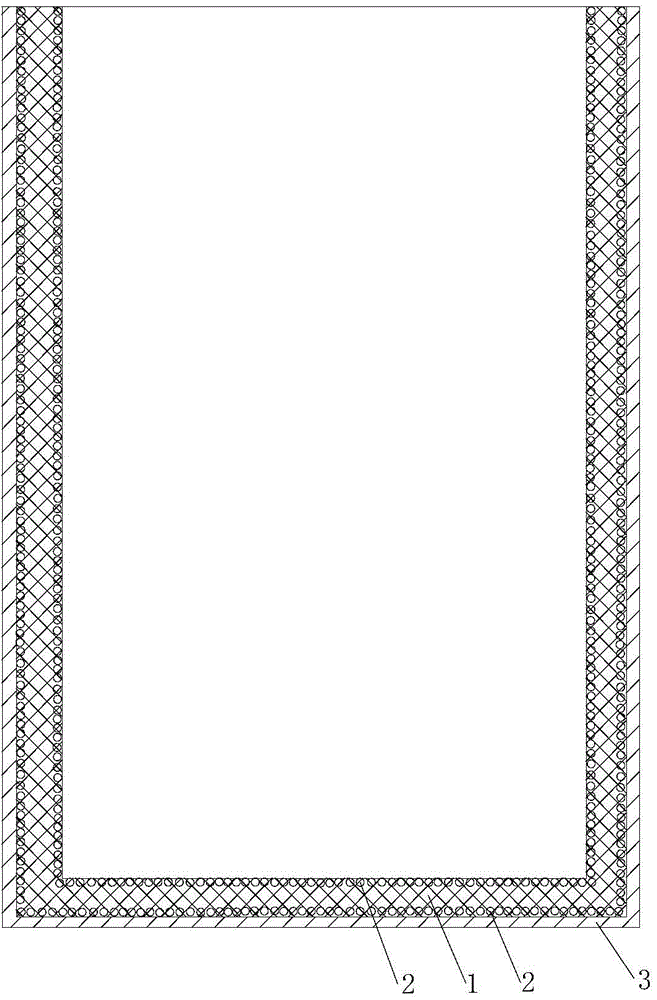

[0008] Such as figure 1 As shown, in the antistatic woven bag of the present invention, the woven bag is made of PVC material 1, the upper and lower surfaces of the woven bag are provided with an antistatic layer 2, and a luminescent layer 3 is arranged on the antistatic layer 2, and the luminescent layer 3 is fluorescent powder layer. The antistatic layer 2 is made of leather treatment agent, acetone and conductive carbon black with a high-speed dispersant after stirring and mixing to make a paint, which is set on the upper and lower surfaces of the PVC material 1 woven bag by dip coating, and the paint is evenly set on the PVC material 1 On the upper and lower surfaces of the woven bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com