Steel wire belt ply oblique crossing type engineering tyre

A technology of engineering tires and steel belts, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as poor wear resistance and puncture resistance, large braking distance, and poor cushioning performance. , to achieve the effects of improved wear resistance and puncture resistance, short tire braking distance and excellent cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

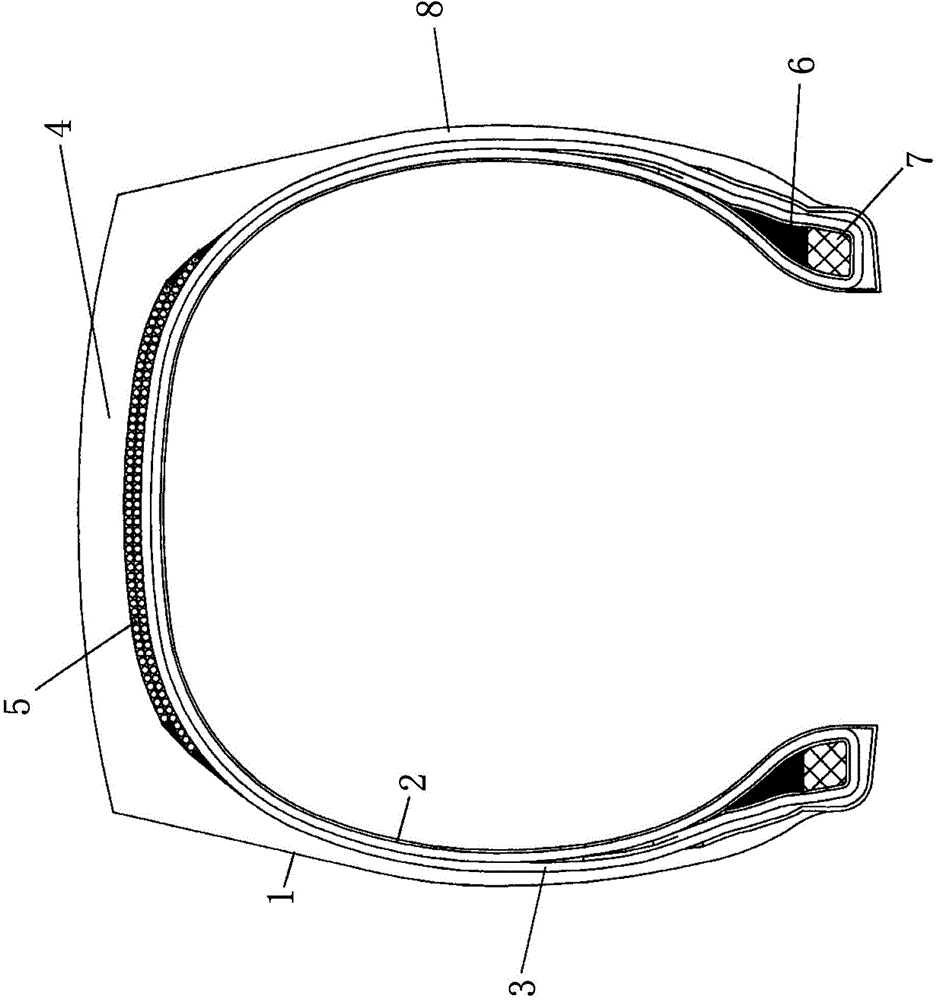

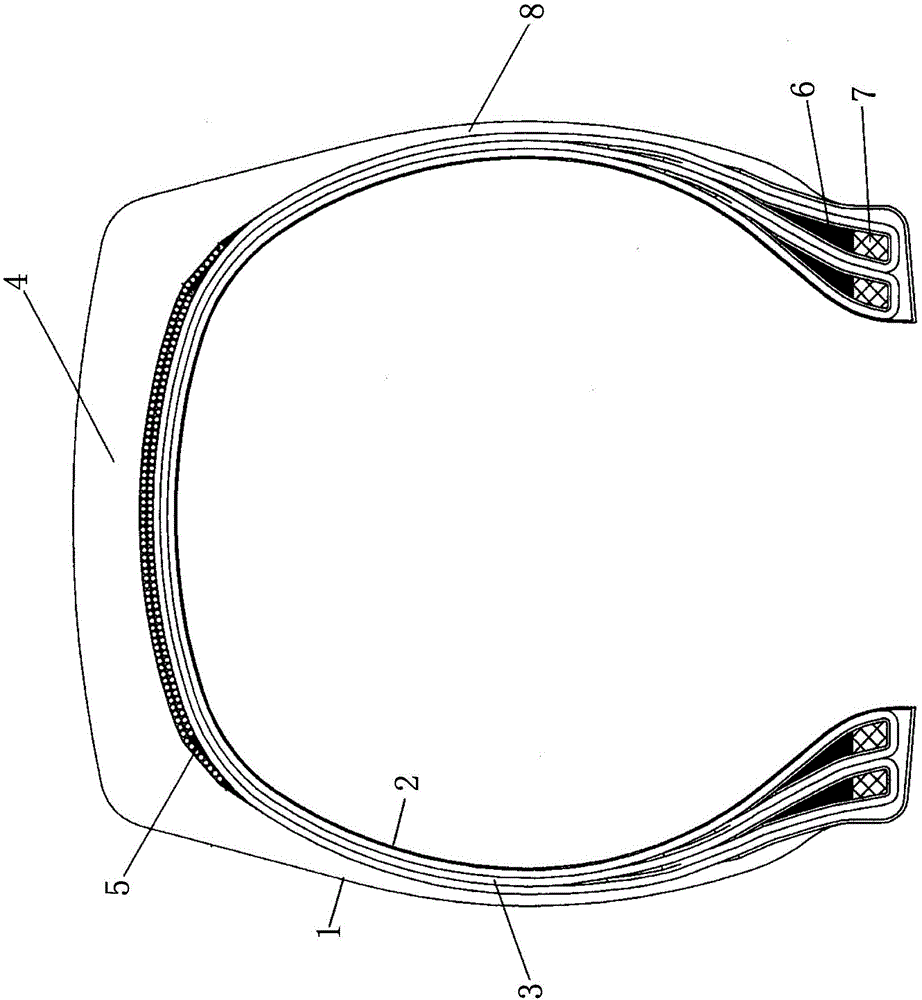

[0015] Such as figure 1 , 2 As shown, the present invention is provided with a nylon cord carcass layer 3 between the tire outer wall 1 and the tire inner wall 2, and a steel wire belt layer 5 is provided between the tire crown body 4 and the nylon cord carcass layer 3, and the cross section is The triangular rubber strip 6 and the steel traveler 7 are arranged on the inner edge of the tire side rubber 8 .

[0016] The number of layers of the steel wire belt layer 5 is 2 layers.

[0017] The rubber strip 6 and the traveler 7 with a triangular cross-section form one or two groups.

[0018] The steel wire belt layer 5 is a two-layer steel wire belt layer with a narrow bottom and a wide top or a narrow top and a wide bottom.

[0019] The finished angle of the steel belt layer 5 is 56°-65° or 58-59°.

[0020] Through the above settings, the present invention is suitable for the equipment of mechanical vehicles such as forklifts and forklifts under complex and severe working co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com