A fully automatic hanging picture rolling packaging machine

A fully automatic, roll-packing technology, which is applied in packaging, decorative arts, paper pasting, etc., can solve the problems of no automatic mechanical shafting, high cost, and low production efficiency, so as to achieve mechanized production, reduce production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

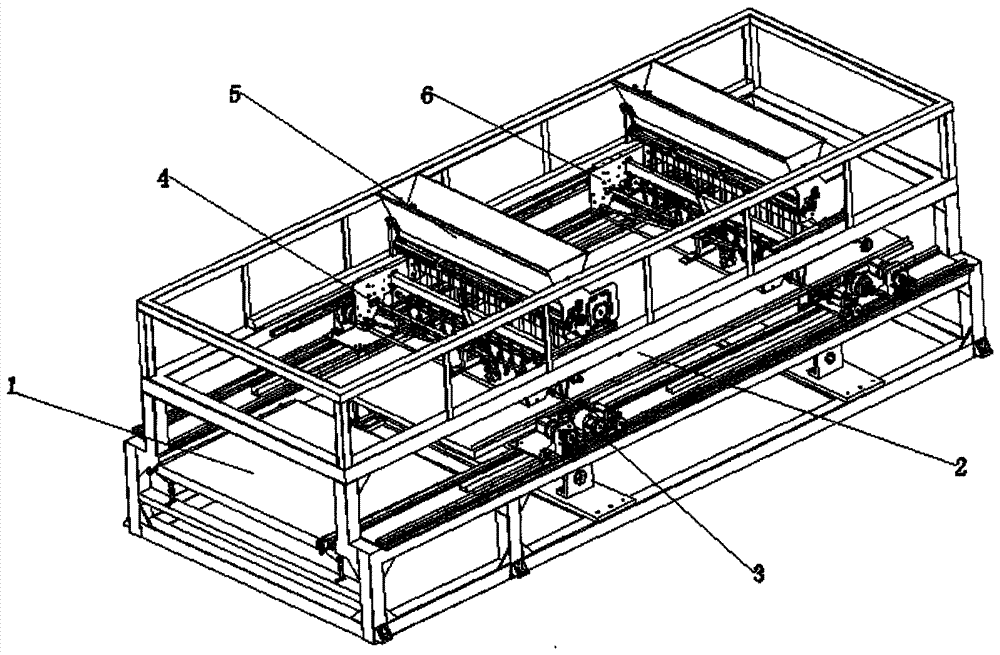

[0027] Such as figure 1 As an example, a kind of fully automatic hanging picture wrapping machine provided by the present invention is composed of a body and a finished product conveyor belt 1 fixed on the body, a lifting platform 2, a rolling device 3, a gluing device 4, and a falling scroll device 5 Composition, the above-mentioned body preferably adopts the upper and lower frame structure, and the lower frame is larger than the upper frame;

[0028] To further illustrate, the above-mentioned finished product conveyor belt 1, lifting platform 2 and rolling device 3 are all fixed on the top surface of the lower frame body, the finished product conveyor belt 1 and the lifting platform 2 are arranged horizontally, the rolling device 3 is perpendicular to both, and the above-mentioned gluing device 4 and the lower picture scroll device 5 are fixed by a fixed plate 6, and the fixed plate 6 is fixed on the upper frame body.

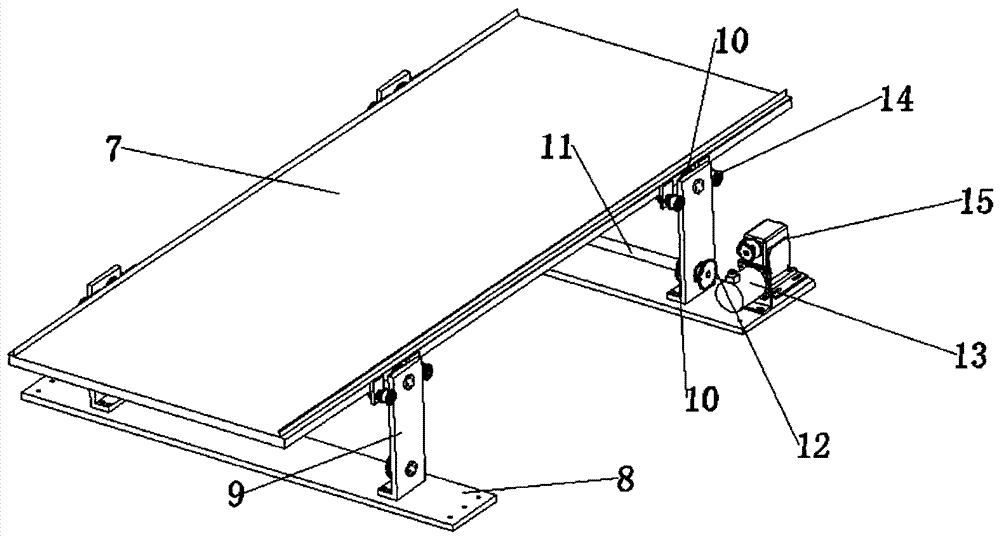

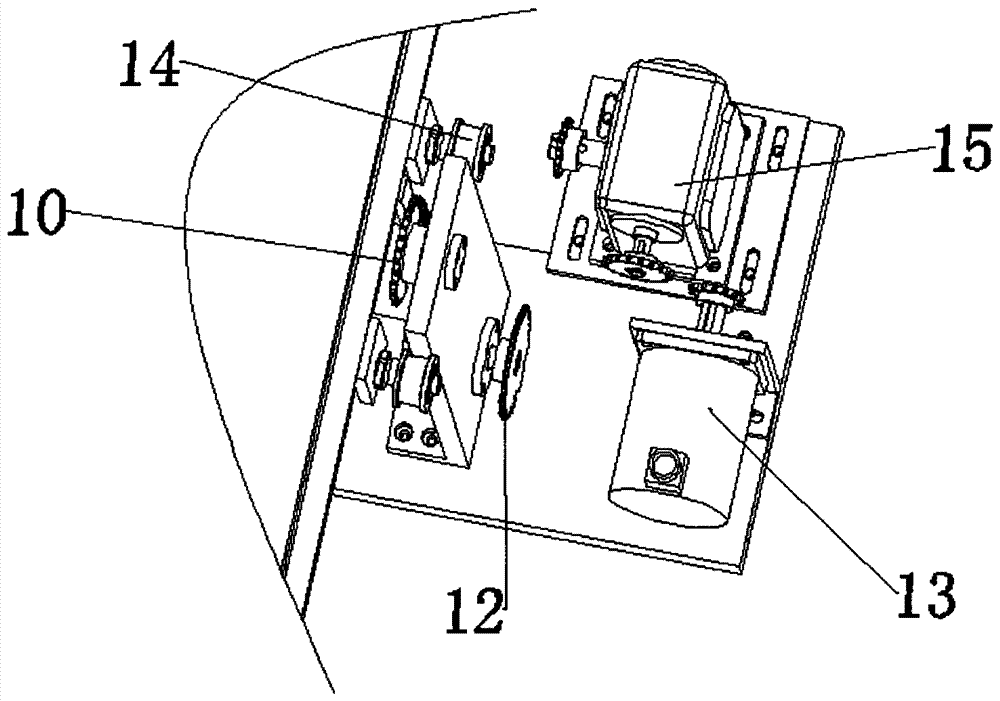

[0029] by figure 2 For example, the lifting platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com