3D printer working platform and positioning method thereof

A 3D printer and working platform technology, applied in the field of 3D printing, can solve the problems of increased printing effect uncertainty, edge warping of printed products, and decline in the quality of printed products, so as to reduce the errors of misalignment and warping of printed products The effect of high efficiency, improved fixed stability, and uniform fixed force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

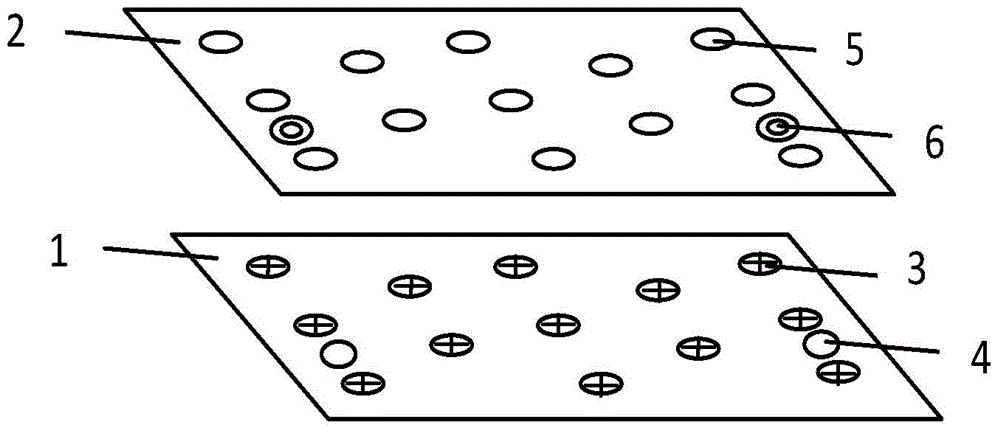

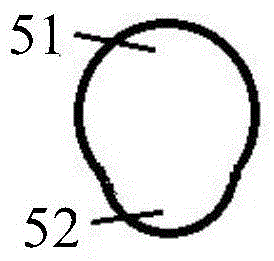

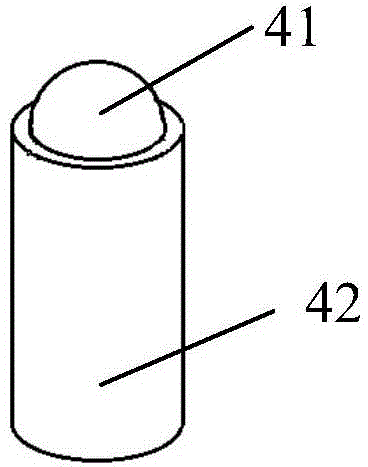

[0022] Such as figure 1 As shown, the working platform of a 3D printer provided by the present invention includes a printing base plate 1 and a printing base plate 2, wherein at least one positioning pin 3 and at least one stepped light-body positioning wave bead 4 are fixed on the printing base plate , the positions corresponding to the positioning pins and the step light body positioning beads on the printing substrate are respectively provided with pin holes 5 and positioning holes 6. Cooperate with the detachable connection of the printing bottom plate.

[0023] The working platform of a 3D printer provided by the present invention has a rectangular printing bottom plate. There are thirteen positioning pins, nine of which are evenly installed on the two diagonals of the rectangular printing base, and the other four are installed at the midpoint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com