Tightening device

A fastening device and fastening technology, which are used in transportation and packaging, wheel assembly and disassembly equipment, and torque/torsional force measurement during tightening, which can solve problems such as difficulty in confirming the tightening torque and setting torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

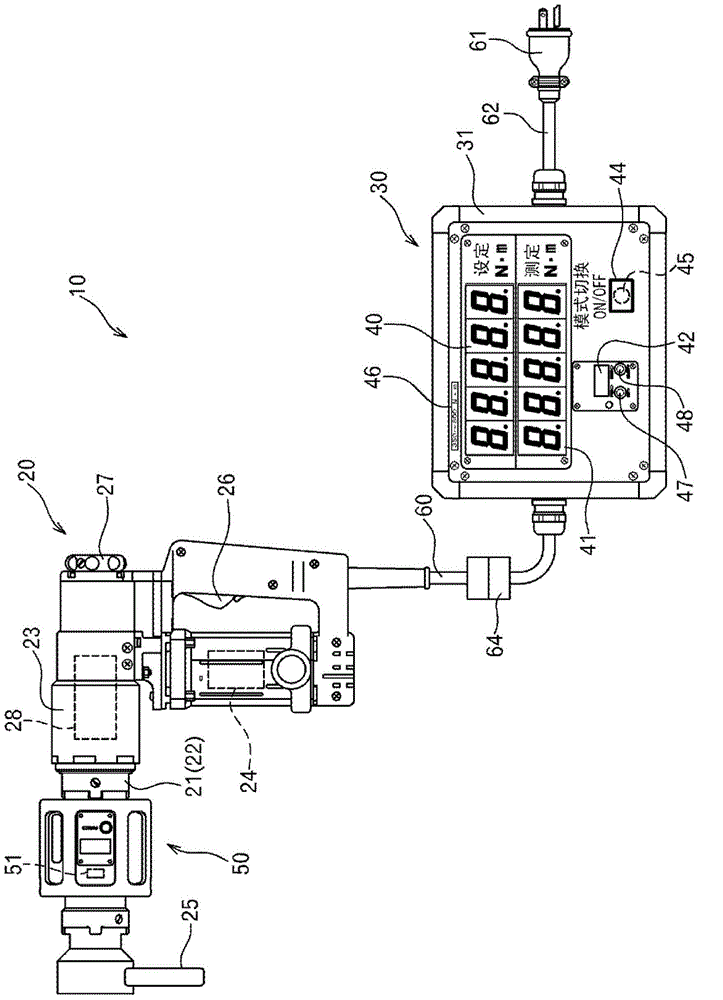

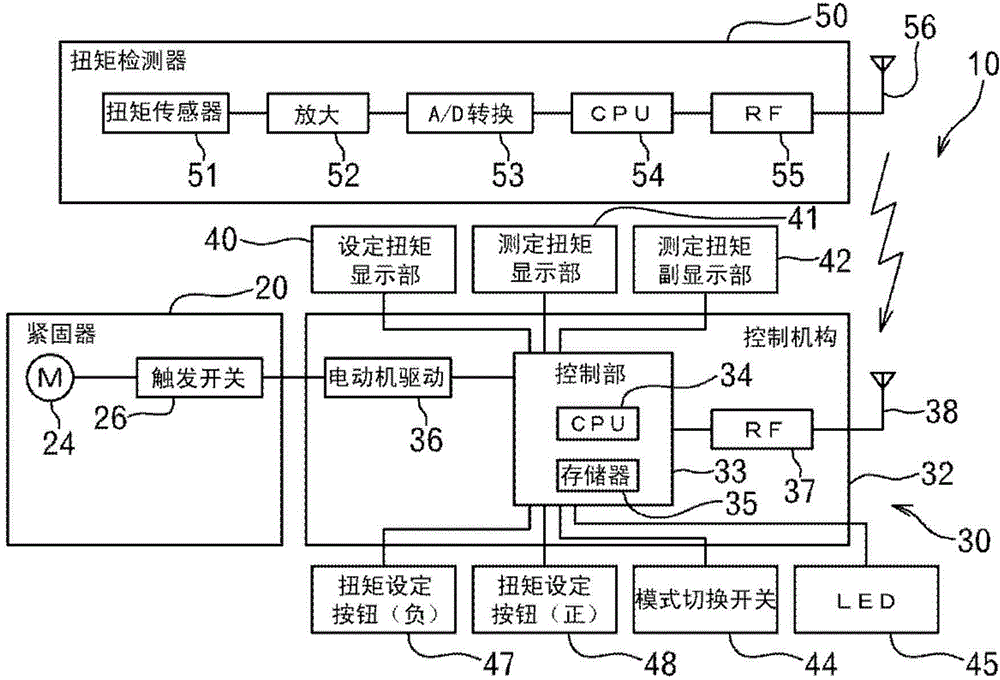

[0032] Hereinafter, an embodiment in which the fastening device 10 of the present invention is applied to a numerically controlled fastening device such as figure 1 as well as figure 2 Tightening is performed as shown, and is composed of a tightener 20 as a main body, a control device 30 for controlling the tightener 20 , and a torque detector 50 for measuring torque. It should be noted that the control device 30 may have a structure in which some or all of its functions are incorporated in the fastener 20 , and may be configured such that a part of the functions of the control device 30 is executed by an external PC or the like.

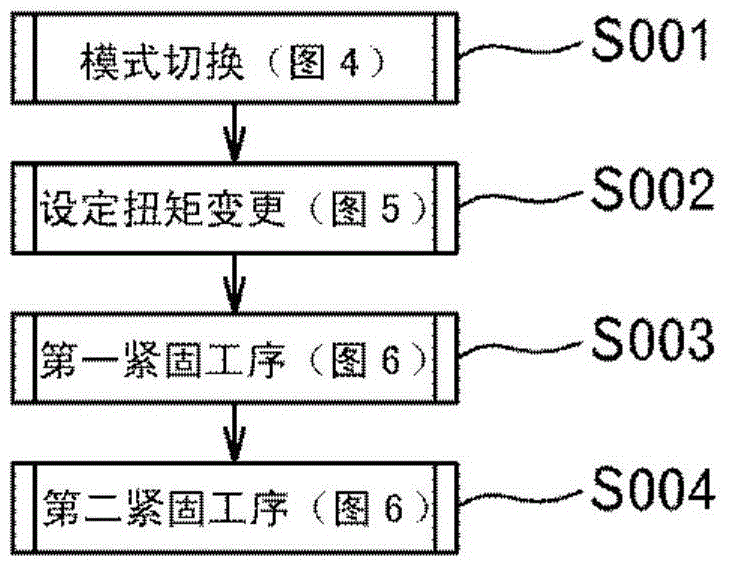

[0033] In addition, in the following embodiments, as image 3 As shown, the fastening process includes a first fastening process and a second fastening process. The first fastening process is a normal fastening mode, and the second fastening process is to confirm whether the tightening torque is above the set torque. fastening mode.

[0034] fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com