Non-uniform pressure field test device and test method in viscous medium pressure forming

A viscous medium and testing device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in testing large diameter ratio thin-walled instability and wrinkling and wrinkle elimination, saving research funds, using The method is fast and convenient, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

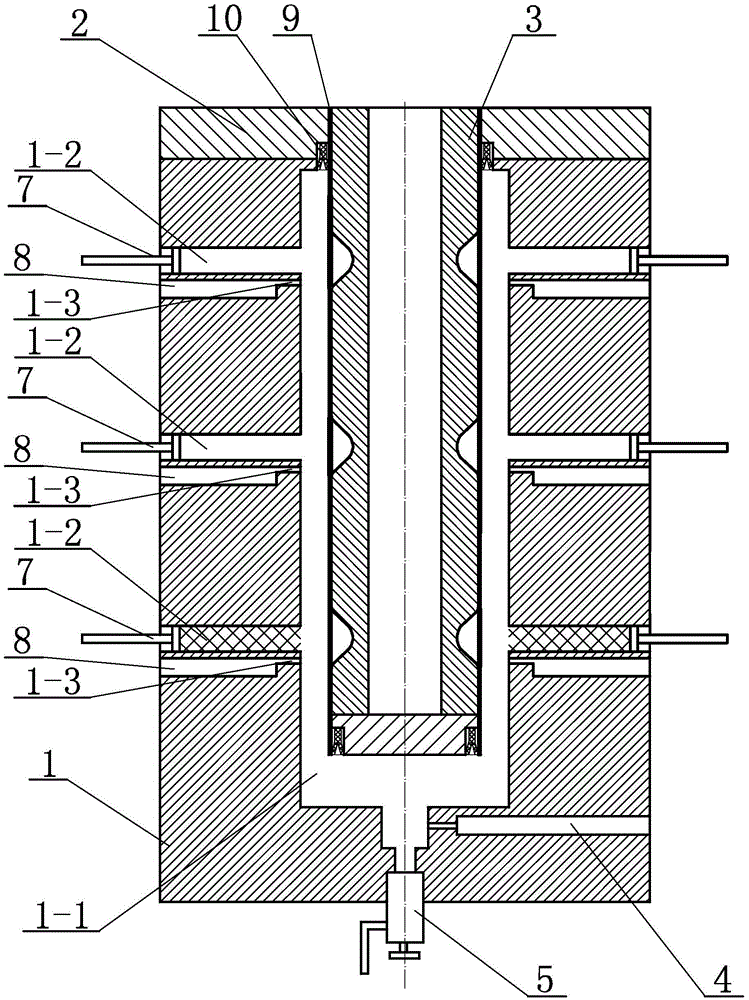

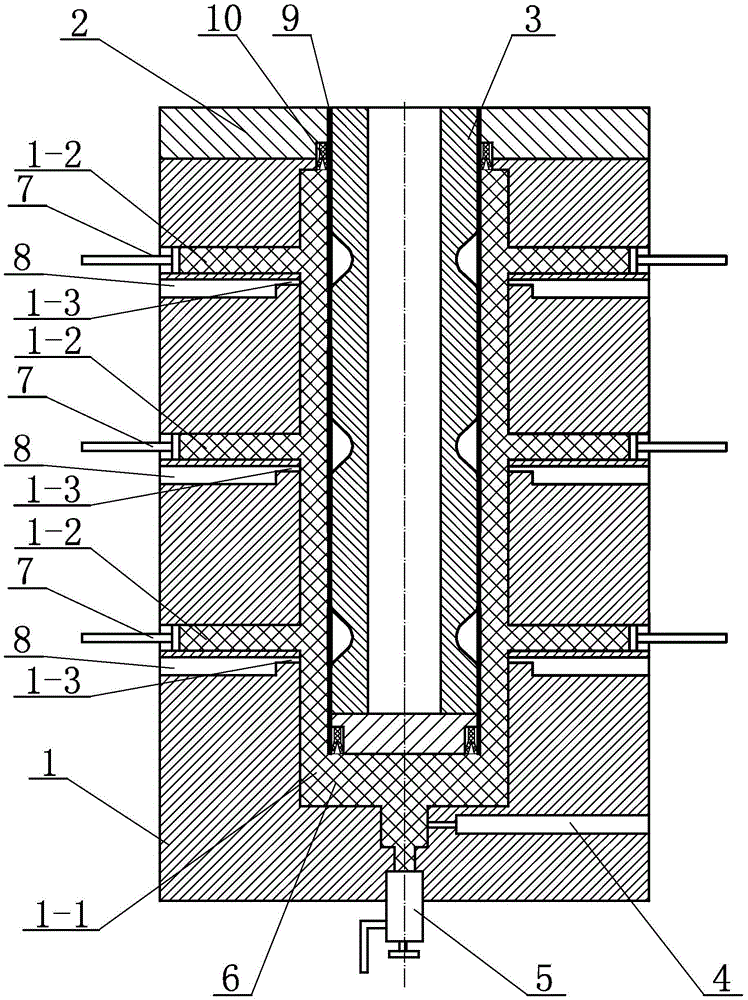

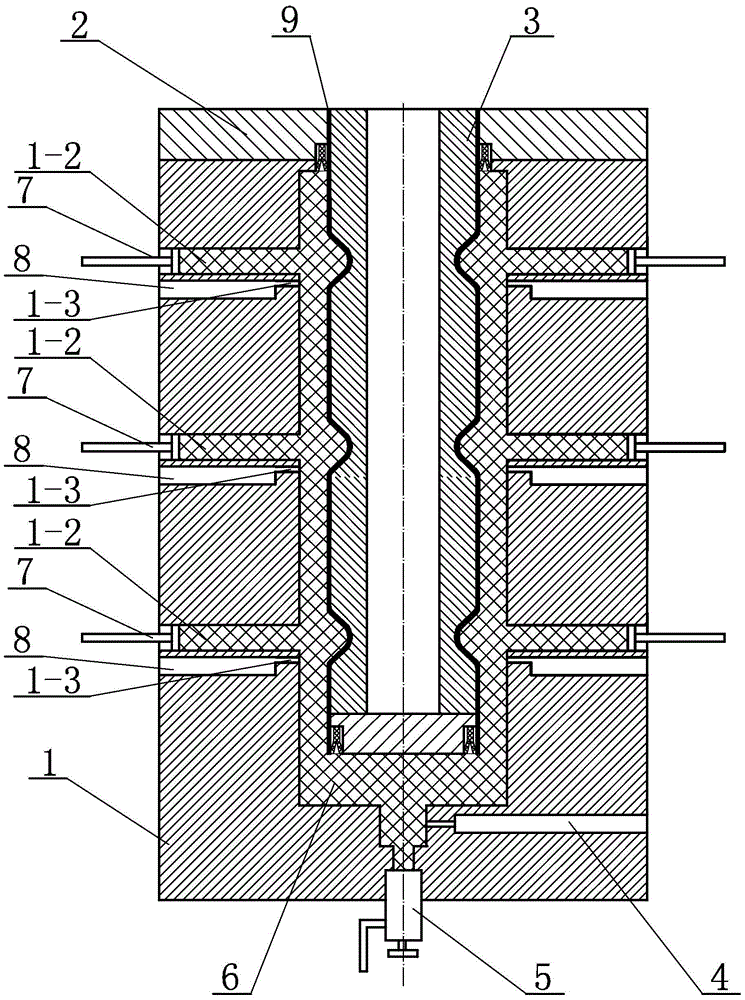

[0033] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 This embodiment is described. In this embodiment, the non-uniform pressure field test device in the viscous medium pressure forming includes a medium chamber 1, an upper clamp cover body 2, a core mold 3, a first pressure sensor 4, a pressure control valve 5, a viscous medium 6 and A plurality of pistons 7, the medium bin 1 is vertically arranged, the upper end of the media bin 1 is provided with an upper clamping cover body 2, and the upper clamping cover body 2 is processed with a vertically arranged insertion hole 2-1, so A vertical medium injection channel 1-1 is processed in the medium bin 1, the insertion hole 2-1 communicates with the medium injection channel 1-1, and the core mold 3 is located in the medium injection channel 1-1 and is connected to the medium injection channel 1-1. The medium injection channel 1-1 is set at a gap, and the medium chamber 1 is also processed...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment. In this embodiment, the medium chamber 1 is a pressure-resistant cavity processed from die steel, etc., the inner diameter of the medium chamber 1 is Φ, the height of the medium chamber 1 is H, and the The value range of the inner diameter Φ is 100mm-300mm, and the value range of the height H is 100mm-500mm. The specific size of the medium bin 1 in this embodiment can be set according to specific experimental requirements and experimental conditions. Other components and connections are the same as those in the first embodiment.

[0038] In this embodiment, the tube blank 9 has a thickness ranging from 0.1mm to 1.5mm, a length of 100mm to 400mm, and a diameter of 80mm to 200mm, which is made of nickel-based superalloy, iron-based superalloy, aluminum alloy, titanium alloy, Made of stainless steel, magnesium alloy, magnesium-lithium alloy or Ni3Al al...

specific Embodiment approach 3

[0039] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment, in this embodiment, a group of piston passage holes is evenly distributed on the same height of the medium chamber 1, and the number of each group of piston passage holes is 4 to 16, and each piston passage hole 1-2 The hole diameter is 5mm ~ 10mm. The piston channel hole 1-2 set in this way is easy to process, and the experimental effect is easy to quantify and convenient to calculate. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com