Helical gear-non-conical gear cross-axis planetary gear system transplanting mechanism for pot seedlings in wide and narrow rows

A non-conical gear and planetary gear system technology, applied in the field of agricultural machinery, can solve the problems of inaccurate seedling picking position, irregular seedling position, large lateral offset, etc., to ensure the success rate of seedling picking, good root system, The effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

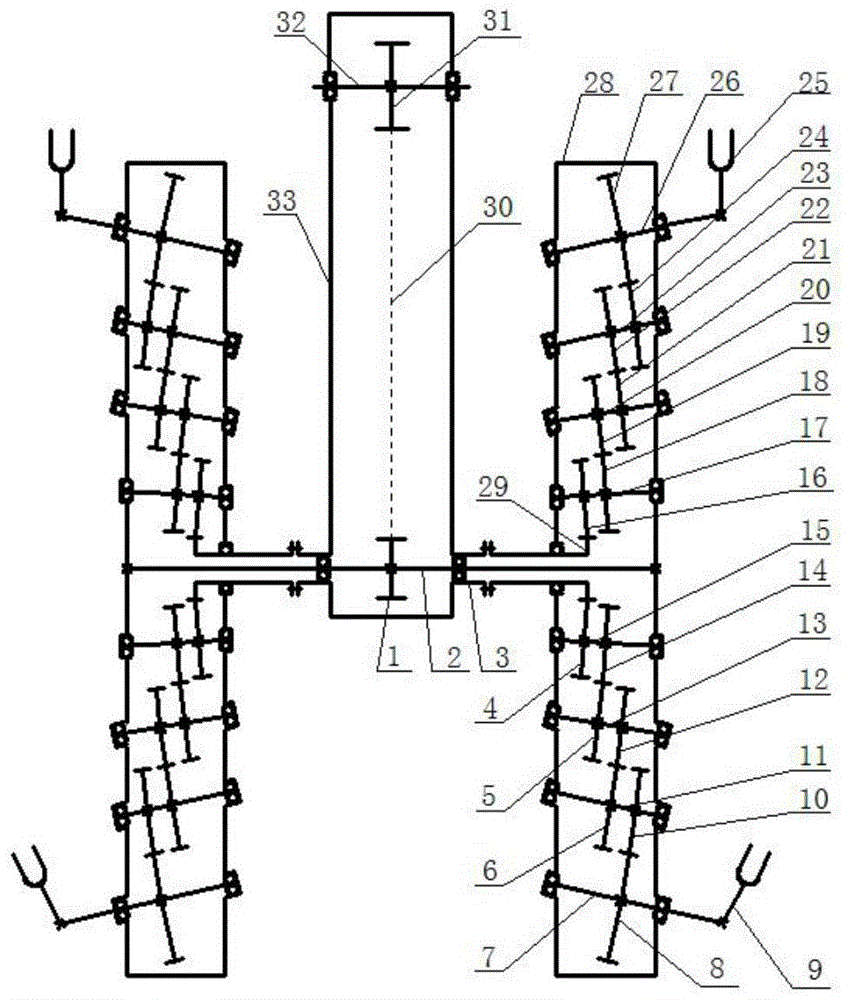

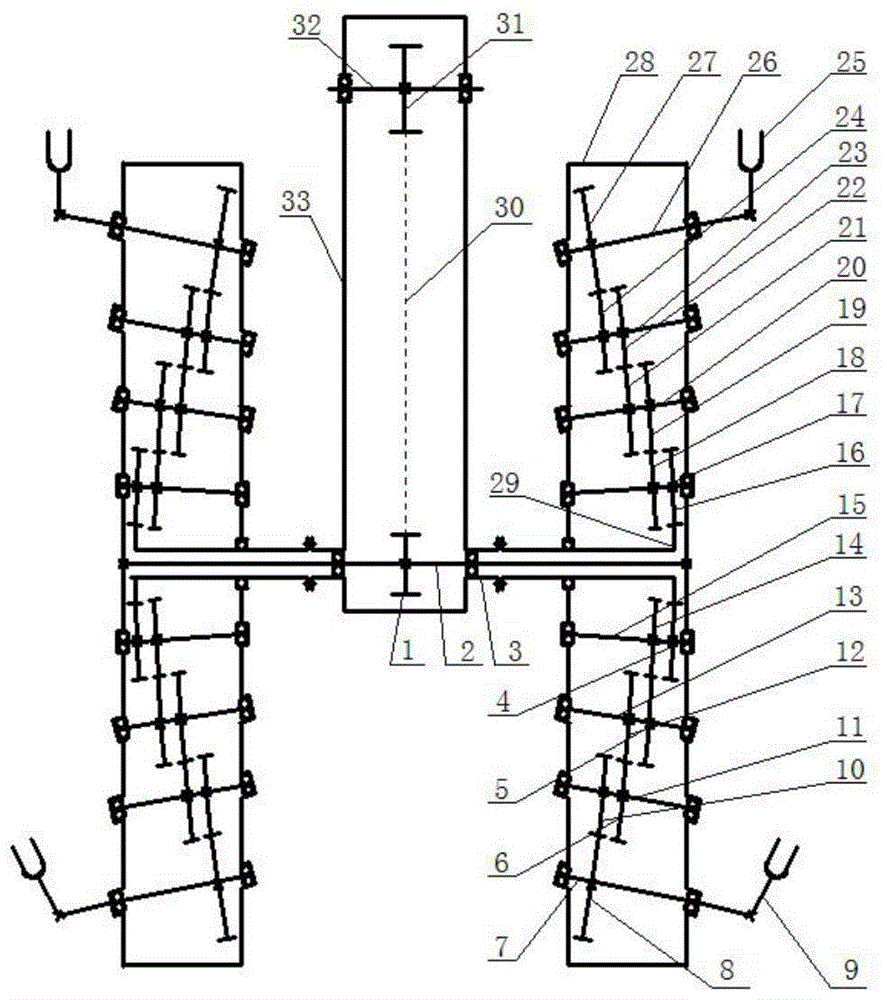

[0038] Such as figure 1 and 2 As shown, the helical gear-non-conical gear staggered axis planetary gear system transplanting mechanism for pot seedlings in wide and narrow rows, including transmission box 33, driving sprocket 31, chain 30, center sprocket 1, central shaft 2, planetary gear system, and upper planting Arm 25 and planting arm 9 down; Central shaft 2 and drive sprocket shaft 32 all are supported on the transmission case 33 by bearing, the drive sprocket 31 that is fixed on the drive sprocket shaft 32 and the center sprocket 1 that is fixed on the central shaft 2 Connected by a chain 30; two planetary gear trains are symmetrically arranged at both ends of the central shaft 2, and the two ends of the central shaft 2 protruding from the transmission box 33 are respectively fixed with a gear box 28 of a planetary gear train.

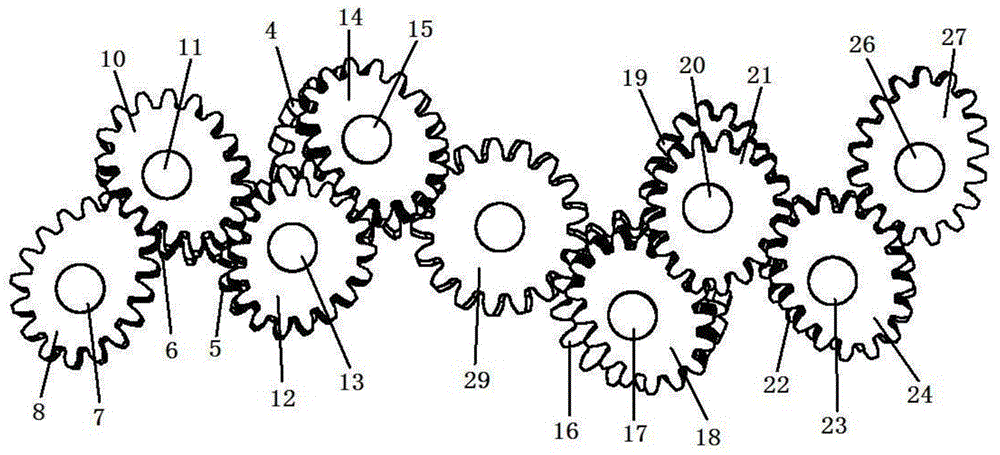

[0039] Such as image 3 and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com