Transparent flexible encapsulation substrate and flexible OLED encapsulation method

A flexible packaging and packaging method technology, applied in chemical instruments and methods, electronic equipment, applications, etc., can solve the problems of non-transparent flexible substrates, limited application scope, etc., to achieve excellent water and oxygen resistance performance, wide application range, Excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

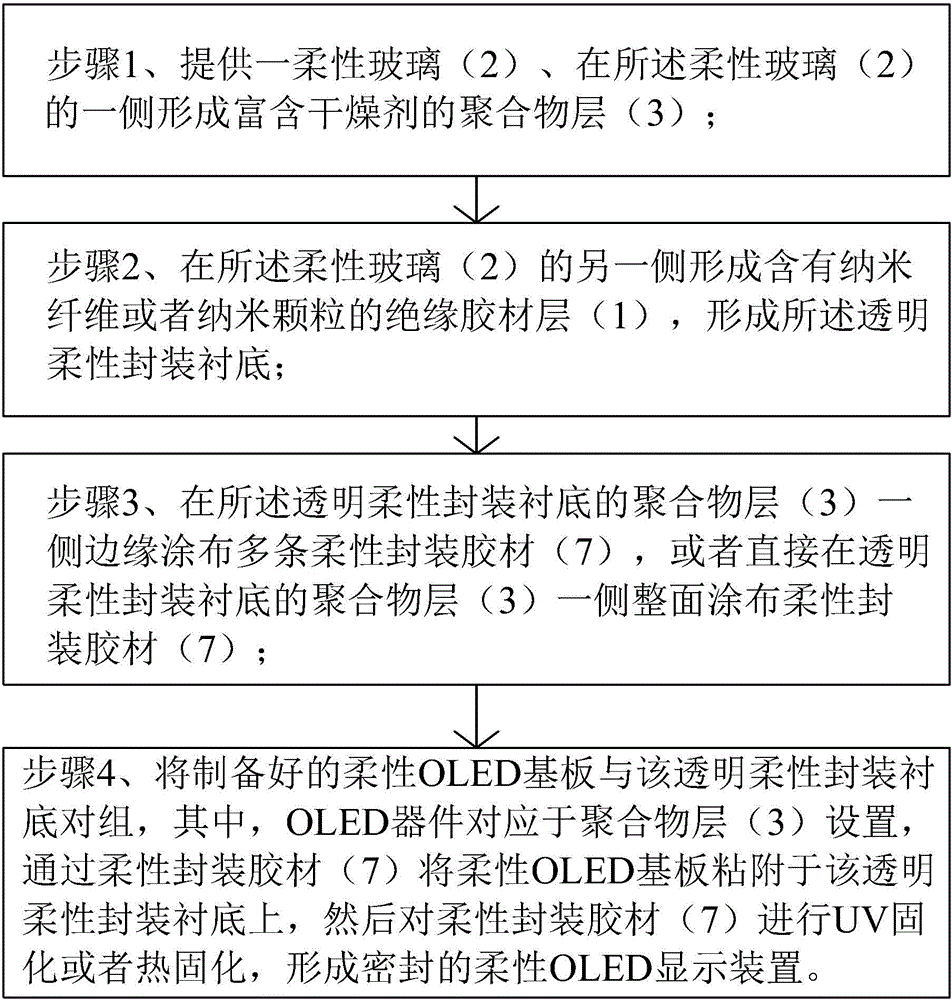

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

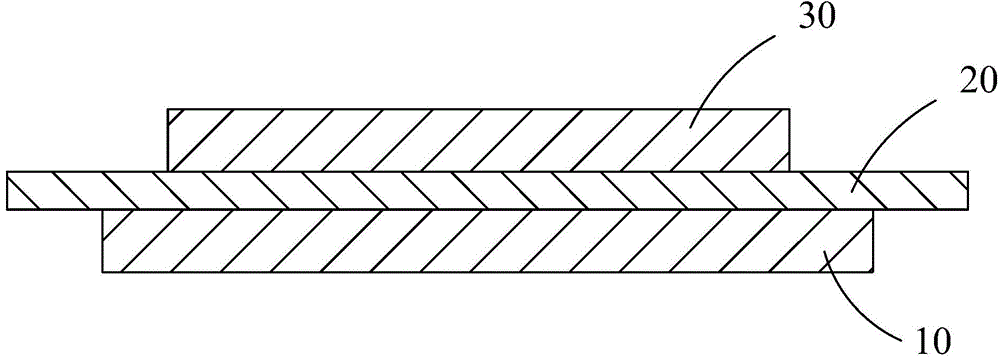

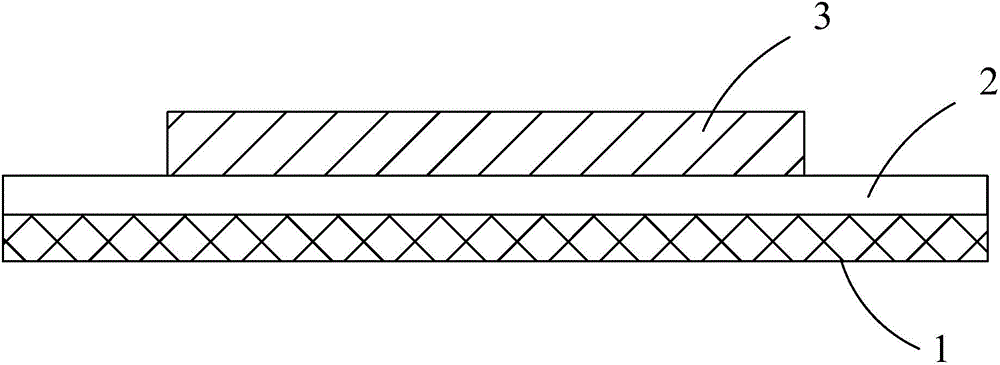

[0034] see figure 2 , the present invention provides a transparent flexible packaging substrate, comprising: flexible glass 2, an insulating adhesive material layer 1 disposed on one side of the flexible glass 2, and a polymer layer 3 disposed on the other side of the flexible glass 2;

[0035] The surface size of the flexible glass 2 is larger than the surface size of the polymer layer 3;

[0036] The surface size of the flexible glass 2 is smaller than or equal to the surface size of the insulating glue layer 1 .

[0037] Specifically, the thickness of the flexible glass 2 is less than 100 um, preferably, the thickness of the flexible glass 2 is 30 to 60 um.

[0038] The main material of the polymer layer 3 is a high-strength functional m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com