Dry-type transformer blade-free cooling fan device and application method thereof

A dry-type transformer and cooling fan technology, which is used in transformer/inductor cooling, temperature control by electric means, machine/engine, etc., which can solve the problem of low cooling efficiency of natural air cooling, unsafe and difficult maintenance of high-speed rotating fan blades and cleaning and other problems, to achieve the effects of low noise, improved overload and short-circuit resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

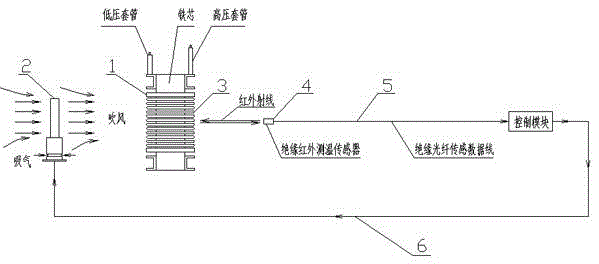

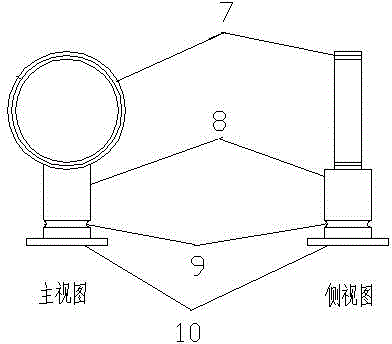

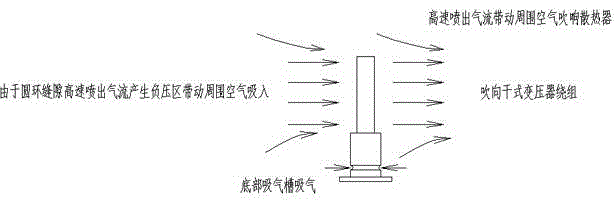

[0028] like figure 1 , figure 2 As shown, this embodiment provides a dry-type transformer bladeless cooling fan device, including a dry-type transformer 1, and also includes a bladeless cooling fan 2, an insulated infrared temperature sensing device 4, and an insulated optical fiber sensing data Line 5, control module and control cable 6; the bladeless cooling fan 2 is arranged near the dry-type transformer 1 and facing the winding 3 of the dry-type transformer, so as to control the dry-type transformer The winding 3 is blown and cooled; the temperature measuring probe of the insulated infrared temperature sensing device 4 is arranged near the winding 3 of the dry-type transformer, and is facing the center of the winding 3 of the dry-type transformer, and its installation distance meets the requirements of the dry-type transformer. The safety distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com