cnc cooperative control device and numerical control system

A technology of collaborative control and speed control, applied in the field of numerical control, can solve problems such as control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below according to the drawings and embodiments. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

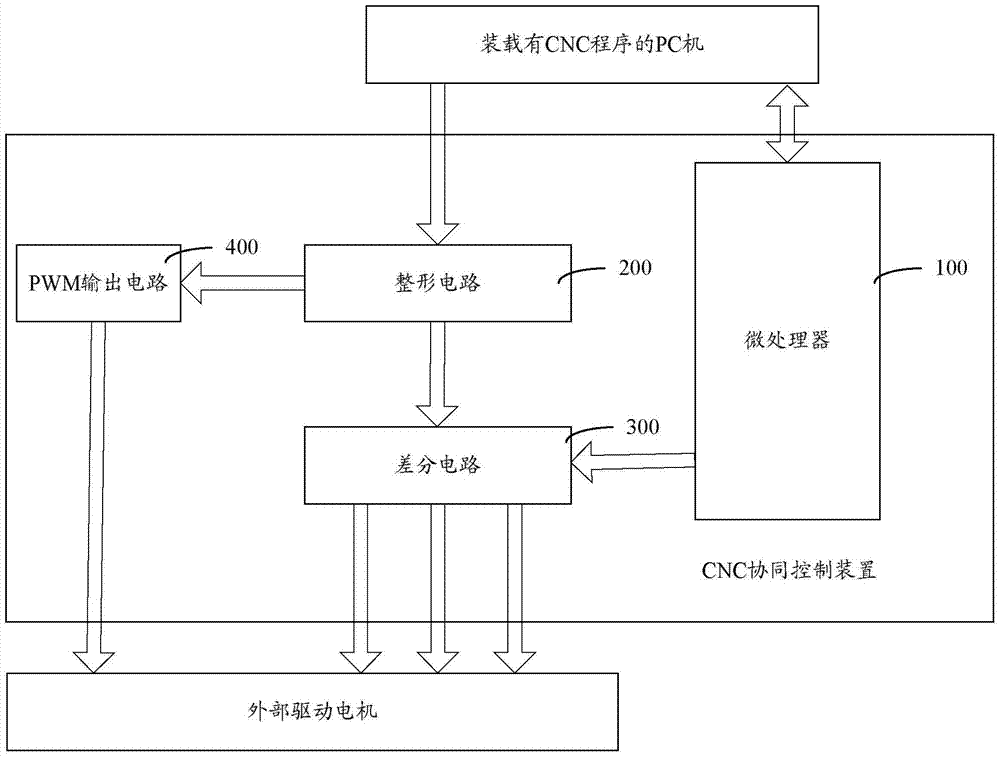

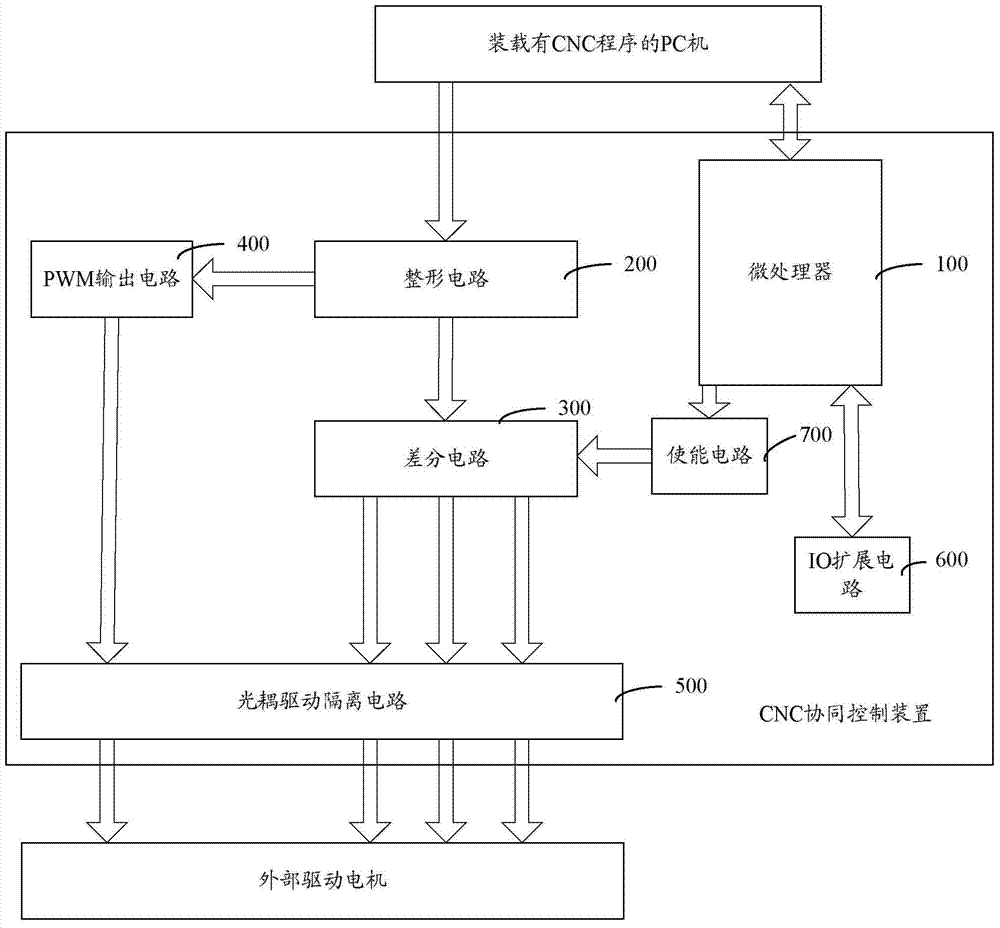

[0014] Such as figure 1 As shown, a CNC cooperative control device includes a microprocessor 100, a shaping circuit 200, a differential circuit 300 and a PWM output circuit 400;

[0015] The input end of the shaping circuit 200 is externally connected to a PC, the first output end of the shaping circuit 200 is connected to the input end of the differential circuit 300, and the second output end of the shaping circuit 200 is connected to the PWM output circuit 400 The input end of the differential circuit 300 and the output end of the PWM output circuit 400 are respectively connected to the external drive motor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com