Leakage non-heat-source optical fiber positioning and orientating system and monitoring method

A fiber optic positioning and orientation system technology, applied in the direction of detection of fluid at the leak point, optical exploration, measurement devices, etc., can solve the problems of affecting the monitoring results, the difficulty of peripheral current heating systems, and threats to the personal safety of operators. To achieve the effect of avoiding seepage leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

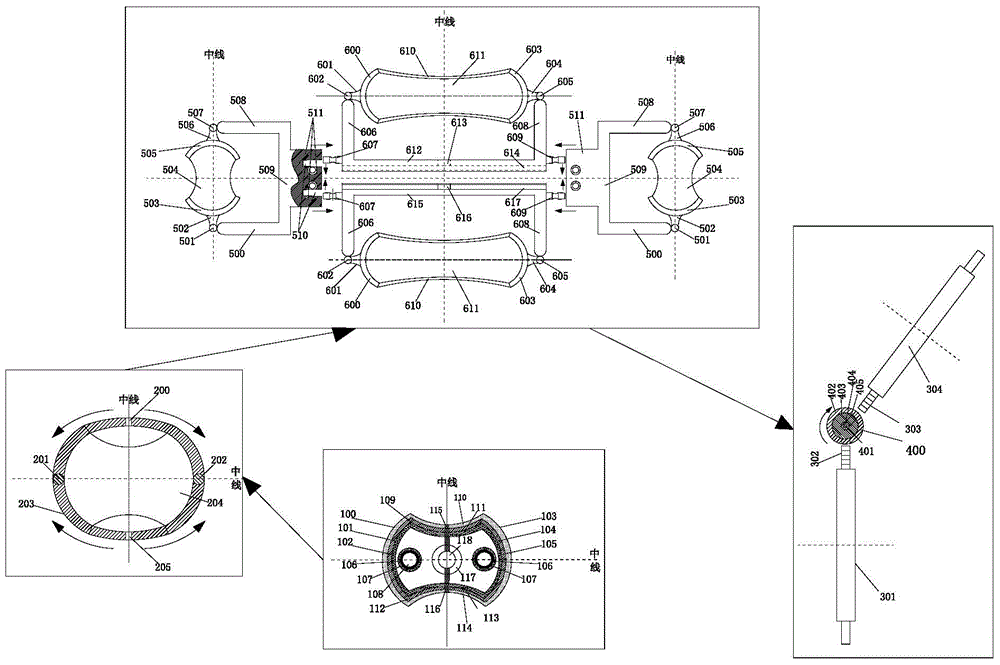

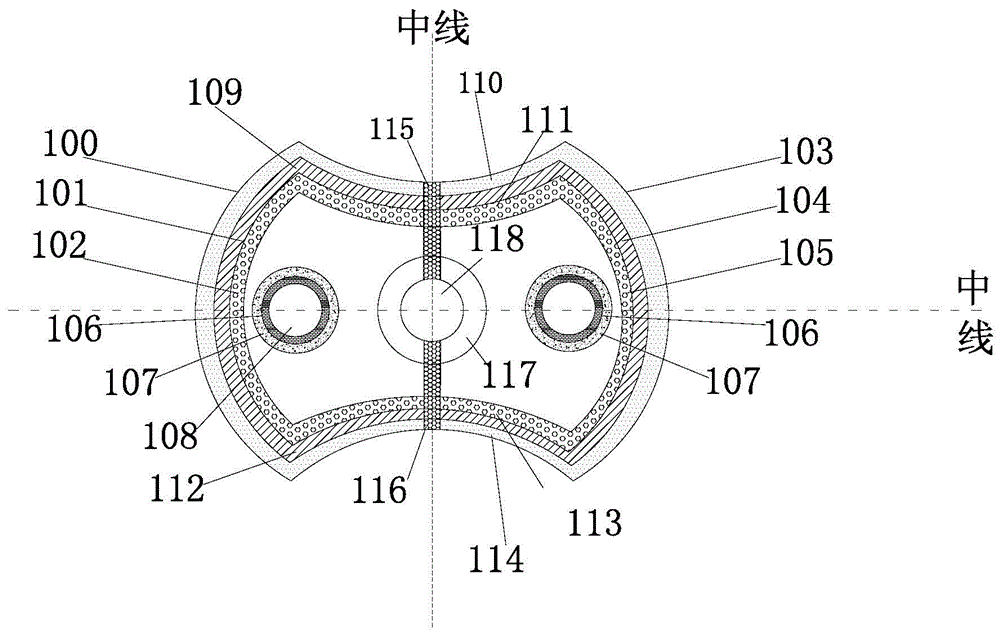

[0040] Such as Figure 1 to Figure 9 As shown, a non-heat source optical fiber positioning and orientation system for leakage of wading structures of the present invention includes several seepage monitoring devices connected by rotating brackets. Symmetrically distributed second seepage monitoring units.

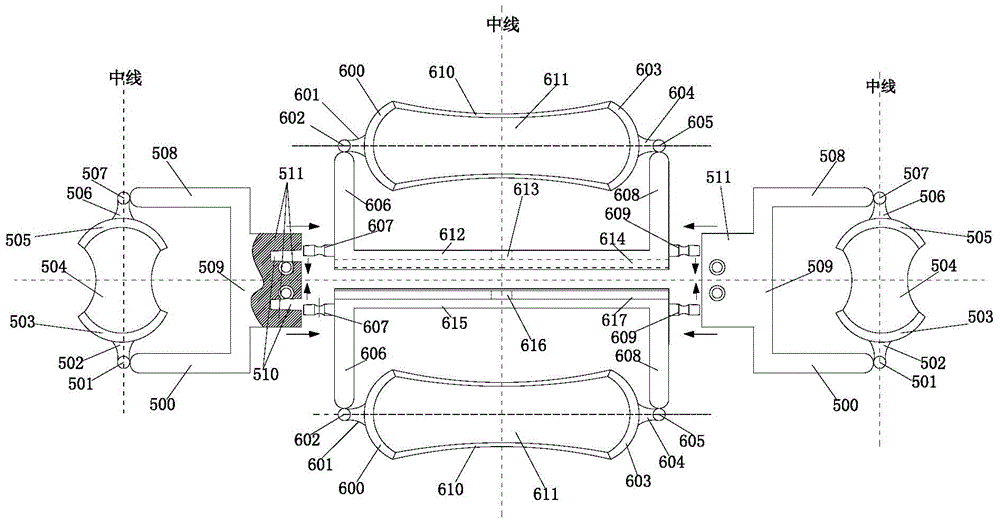

[0041] The first seepage monitoring unit includes the first fiber-carrying groove 611 for fixing the monitoring fiber unit, the first fiber-carrying groove 611 is provided with a fiber-carrying sheath 610, and the two ends of the first fiber-carrying groove 611 are respectively provided with left fiber-carrying channels end 600 and the right fiber end 603, the left fiber end 600 is connected to the left ball 602 through the left handle 601, the right fiber end 603 is connected to the right ball 605 through the right handle 604, the left ball 602 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com