A device and method for solidification experiments of material samples in a simulated microgravity environment

A technology for simulating microgravity and samples, applied in the field of space material science research, can solve the problems of complex operation, high price, sample damage, etc., and achieve the effects of simple device structure, low production cost, and short falling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

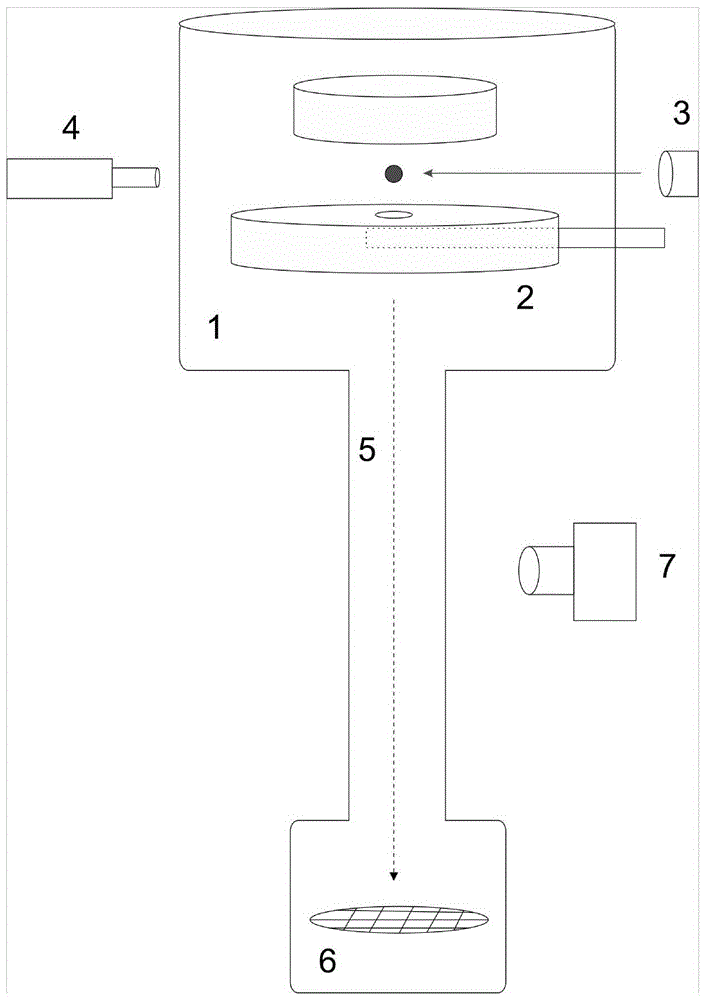

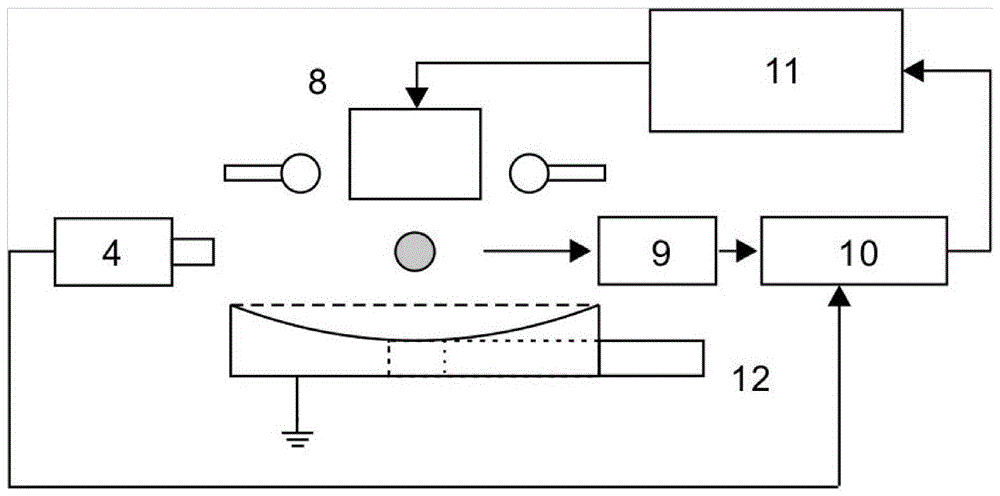

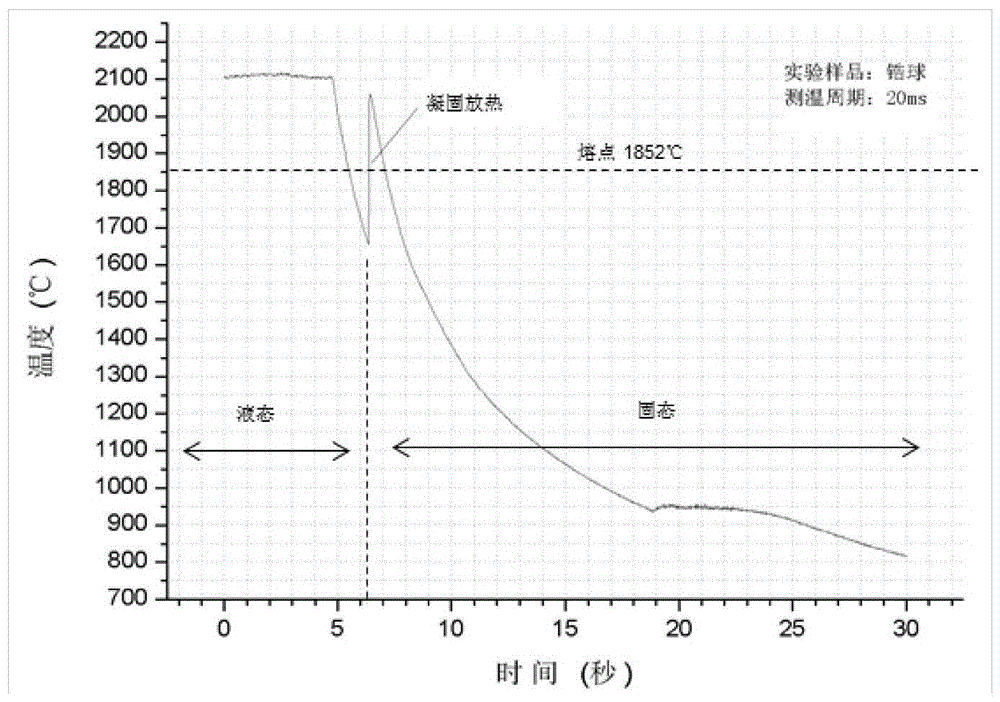

[0045] Such as figure 1 As shown, a device for simulating the solidification experiment of material samples in a microgravity environment, including: a vacuum container 1, an electrostatic levitation control and release device 2, a heater 3, a thermometer 4, a short drop tube 5, a recovery tray 6 and a camera 7; the vacuum container 1 is a vacuum closed container; the electrostatic levitation control and release device 2 is located on the top of the vacuum container 1, and is used to control the material sample in a suspended state or a falling state; the material sample passes through the short drop tube 5 Fall into recovery tray 6, and described recovery tray 6 is positioned at the bottom of vacuum container 1, is used for reclaiming the material sample after solidification; Described heater 3, thermometer 4 and camera 7 are positioned at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com