A Method of Detecting Bubble Defects in Glass Based on Mie Scattering

A glass and bubble technology, which is applied in the field of detection of bubble defects inside flat glass, can solve the problems of inability to obtain depth and size information, inability to directly obtain, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the embodiments and drawings, but the present invention is not limited thereto.

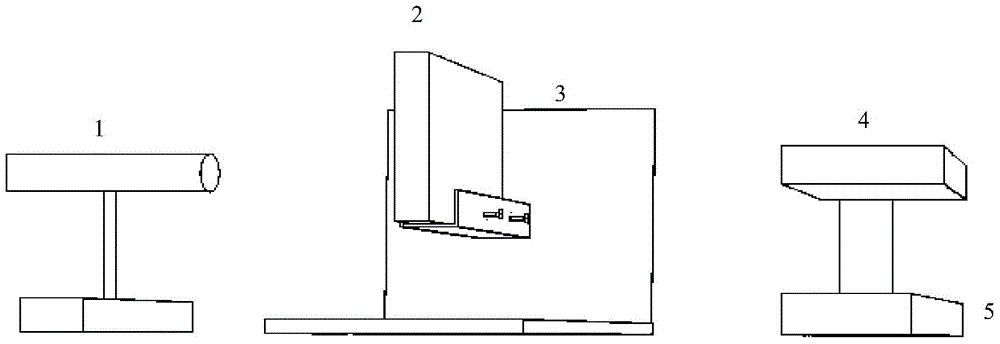

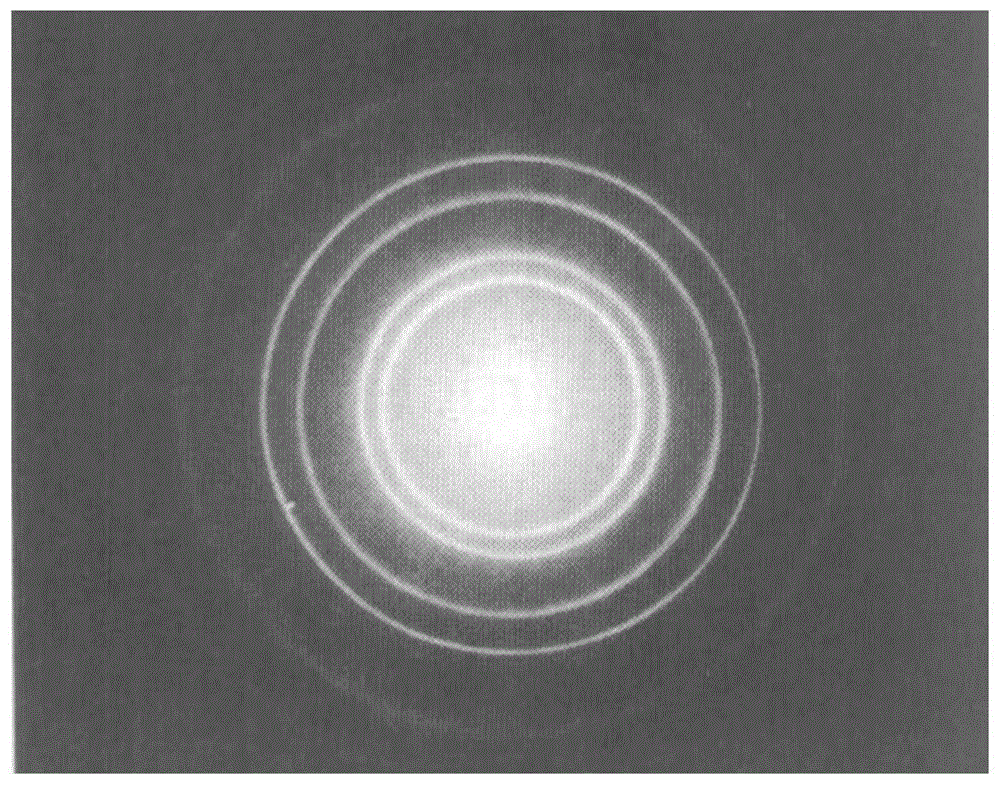

[0024] Such as figure 1 As shown, the detection device of the present invention includes a laser 1, a first translation stage 3, a CCD detection device 4 and a second translation stage 5, the first translation stage 3 is used to move the measured glass 2, and the second translation stage 5 is used to move CCD detection device 4. The photosensitive chip of the CCD detection device 4 is Sony IC×445, the size of the target surface is 1 / 3 inch, and the pixel size is 3.75um×3.75um. The laser is a 532nm monochromatic laser, the spot mode is TEM00 mode, the beam diameter is 1.5mm, and the beam divergence angle is less than 1mrad.

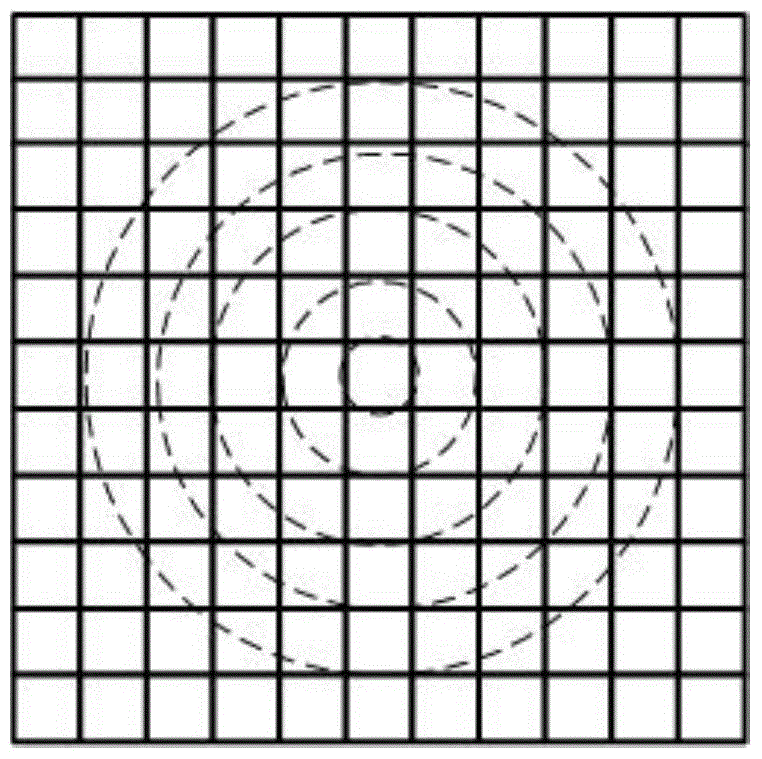

[0025] The present invention a kind of method based on Mie scattering detection bubble defect inside glass, comprises the following steps:

[0026] (1) After the energy of the 532nm monochro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| light angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com