Mg(OH)2-based phosphorus binding film as well as preparation and application thereof

A technology that combines membranes and tetramethylethylenediamine, which is applied in the preparation of test samples, surface/boundary effects, and measurement devices, and can solve the problems that cannot meet the requirements of phosphorus determination and analysis, large particles of surface fixatives, and complicated preparation processes and other problems, to achieve the effects of shortening the film forming time, high selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

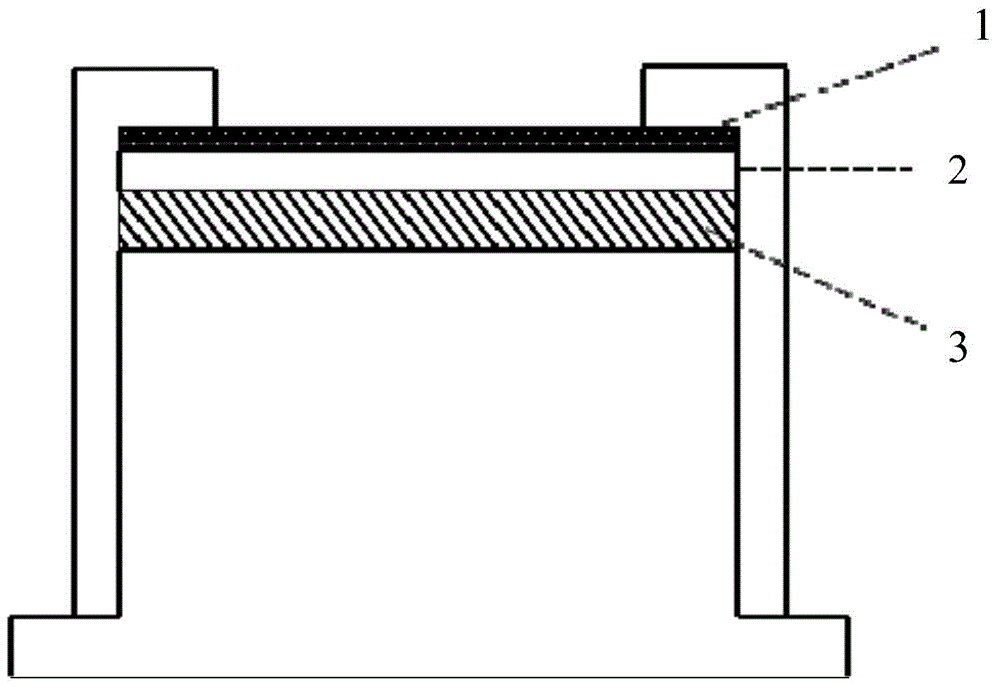

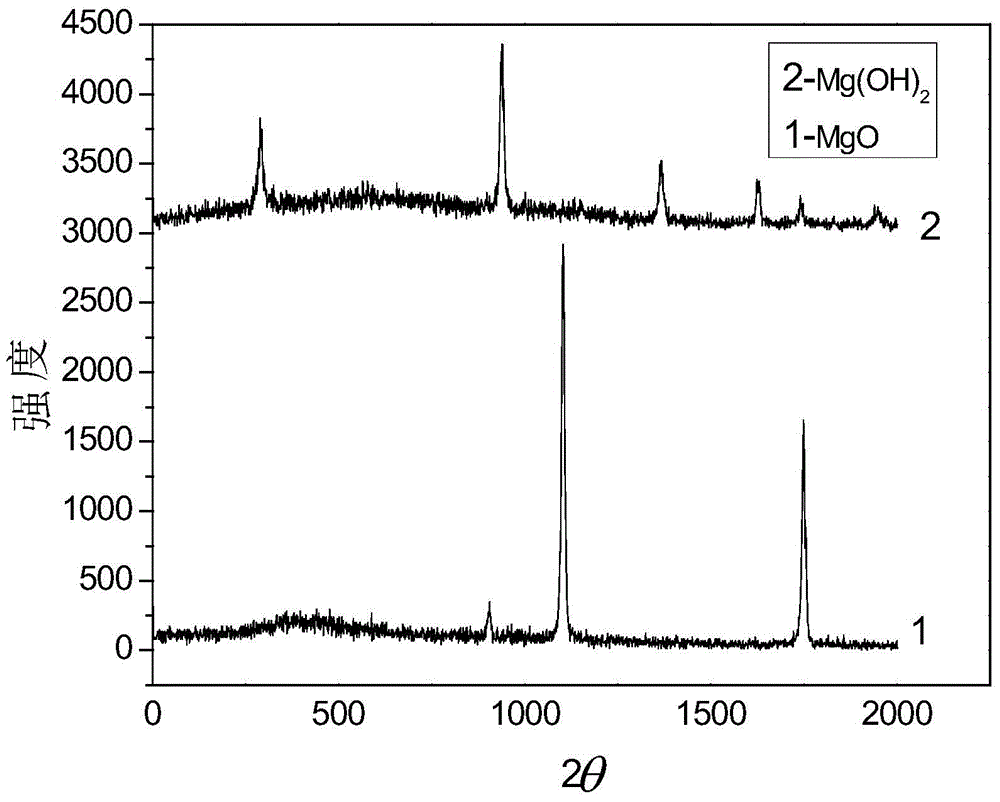

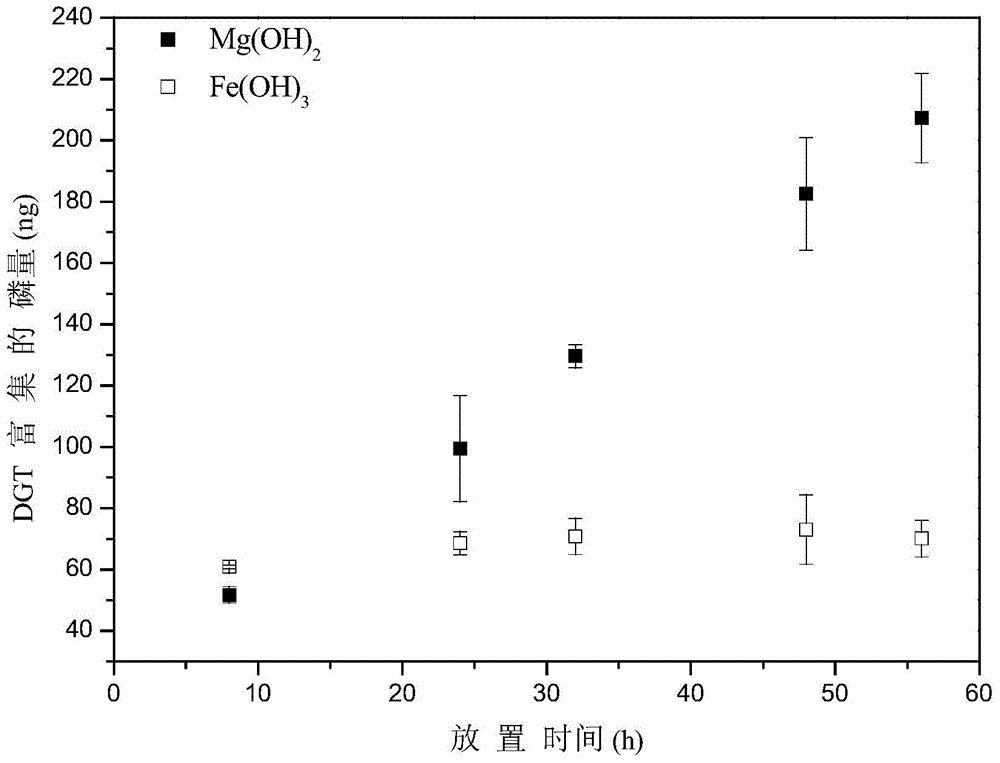

[0033] (1) Mix the MgO and acrylamide prepolymerization solution according to the mass volume ratio of 1:1.1, and add the same volume of deionized water as the acrylamide prepolymerization solution. The acrylamide prepolymerization solution consists of 15% acrylamide and 0.3% It is prepared from a mixed aqueous solution of N,N'-methylenebisacrylamide; (2) add 30 μL of 10% ammonium persulfate solution and 4 μL of tetramethylethylenediamine to the above solution, and stir well; (3) mix Slowly inject the above solution into the gap between two glass plates sandwiched with a U-shaped plastic sheet, drive out the air bubbles, place the glass plate in an oven at 30±2°C for 10 minutes, and cool it to room temperature naturally; (4) Put the glass plate in Soak in deionized water at 25±0.5°C for 2 hours to fully hydrate magnesium oxide to form magnesium hydroxide. figure 2 It can be seen that MgO is completely hydrated to form Mg(OH) 2 . Remove the mold and take out the Mg(OH) 2 Ph...

Embodiment 2

[0035](1) Mix the MgO and acrylamide prepolymerization solution according to the mass volume ratio of 1:2.2, and add the same volume of deionized water as the acrylamide prepolymerization solution. The acrylamide prepolymerization solution consists of 28.6% acrylamide and 1.5% It is prepared from a mixed aqueous solution of N,N'-methylenebisacrylamide; (2) Add 200 μL of 10% ammonium persulfate solution and 25 μL of tetramethylethylenediamine to the above solution, stir well, and the above ammonium persulfate Potassium persulfate can also be used instead. (3) Slowly inject the above solution into the gap between two glass plates sandwiched with a U-shaped plastic sheet, drive out the air bubbles, place the glass plate in an oven at 46±2°C for 30 minutes, and cool it to room temperature naturally; (4) Soak the glass plate in deionized water at 30±0.5°C for 5 hours to fully hydrate the magnesium oxide to form magnesium hydroxide. Remove the mold and take out the Mg(OH) 2 Phosph...

Embodiment 3

[0037] (1) Mix MgO and acrylamide prepolymerization solution at a mass volume ratio of 1:1.165, and add the same volume of deionized water as the acrylamide prepolymerization solution. The acrylamide prepolymerization solution consists of 21.8% acrylamide and 0.9% (2) Add 115 μL of 10% potassium persulfate solution and 14.5 μL of tetramethylethylenediamine to the above solution, stir well, and the above Ammonium sulfate can also be replaced by potassium persulfate. (3) Slowly inject the above solution into the gap between two glass plates sandwiched with a U-shaped plastic sheet, drive out the air bubbles, place the glass plate in an oven at 38±2°C for 20 minutes, and cool it to room temperature naturally; (4) Soak the glass plate in deionized water at 27.5±0.5°C for 3.5 hours to fully hydrate the magnesium oxide to form magnesium hydroxide, remove the mold and take out the Mg(OH) 2 Phosphorus-based binding membranes, cut into desired shapes, and soaked in deionized water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com