Method for diagnosing engine failure

A fault diagnosis and engine technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as data false alarms, and achieve the effect of improving objectivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention include the shape, structure, mutual position and connection relationship of each part, the function and working principle of each part, and the manufacturing process of the various components involved. And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

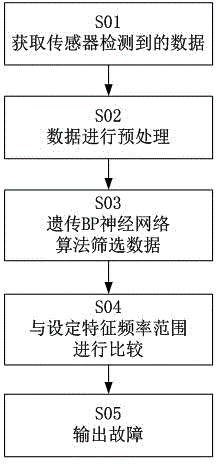

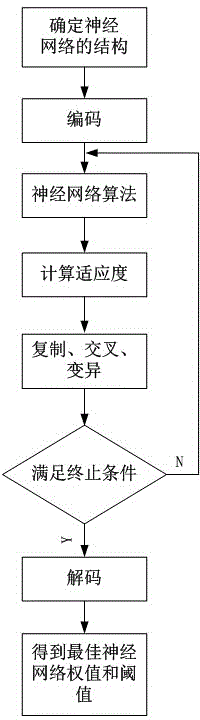

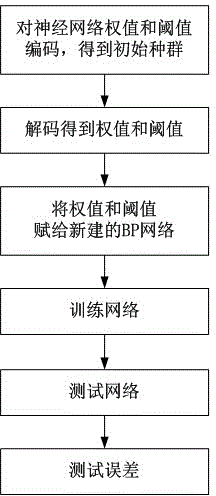

[0019] An engine fault diagnosis method, which uses the genetic BP neural network algorithm to screen the data detected by the sensor to select the best sensor measurement value, and then compares it with the characteristic frequency range set by the system to draw a fault conclusion. Ordinary sensor data is always sent to the data controller for real-time comparison and processing of data with high a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com