Test method and device for testing sealing property of pipe-jacking construction device

A technology of construction device and test method, applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc. It can reduce the construction safety risks, reduce the installation cost and ensure the success rate.

Inactive Publication Date: 2015-04-29

CHINA UNIV OF GEOSCIENCES (WUHAN)

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the starting and receiving of pipe jacking is an important risky stage of pipe jacking construction, especially in unfavorable strata such as soft soil and sandy soil with high groundwater pressure, accidents such as water gushing, sand gushing or ground subsidence often occur, and construction safety risks If it is serious, it will cause the failure of the entire pipe jacking project, and even pose a threat to the safety of the surrounding existing buildings.

At the same time, in the curved pipe jacking under complex conditions, if the sea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

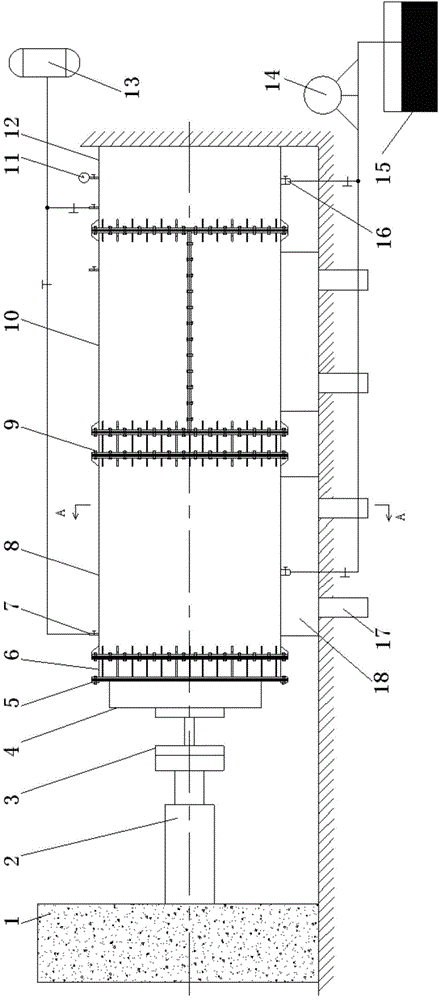

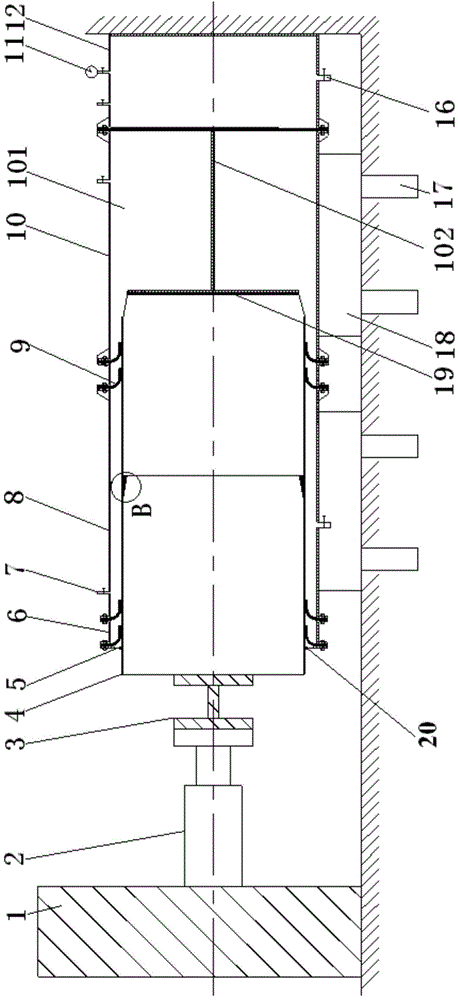

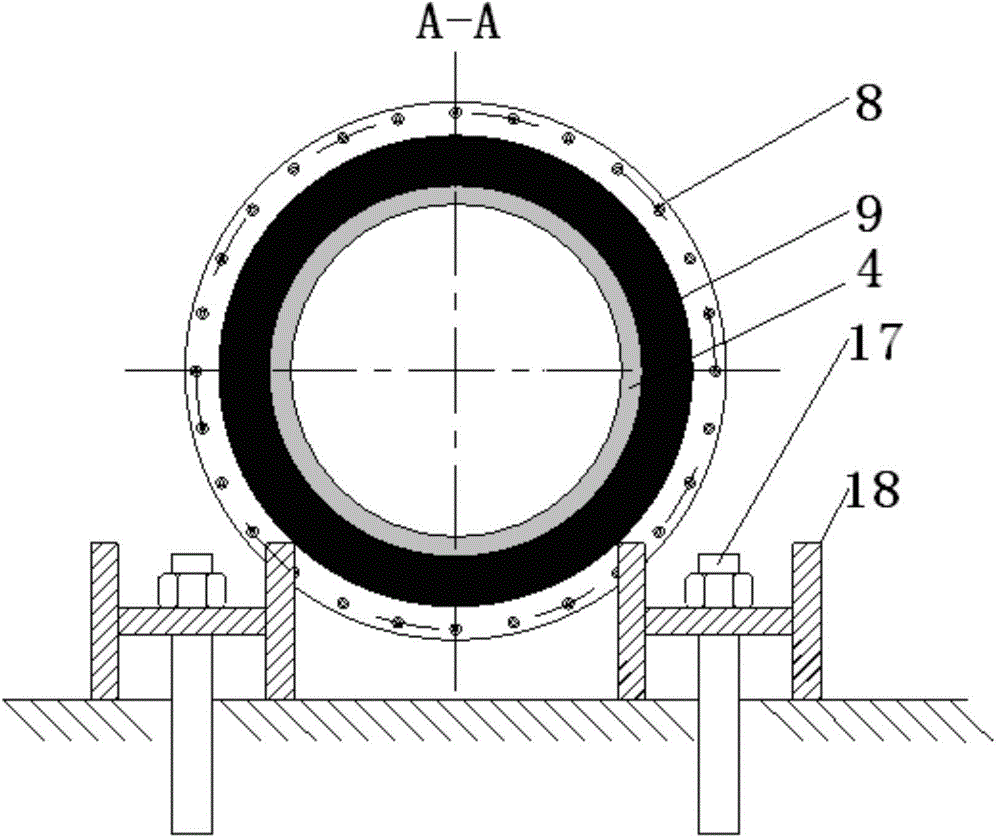

The invention provides a test method and device for testing the sealing property of a pipe-jacking construction device. The two ends of a receiving bin are provided with sealing rings and connected with a pressure stabilizing bin to form a pipe-jacking receiving device. A casing pipe is installed at the rear end of the pipe-jacking receiving device. A starting opening water stopping sealing device is installed at the rear end of the casing pipe, and pipe joint sets are jacked forward in sequence to enable the front ends to enter the receiving bin and the rear ends to be located outside the casing pipe, so that a sealing cavity is formed between the casing pipe and the pipe joint sets, and a sealing cavity is formed between the pipe-jacking receiving device and the pipe joint sets; the two sealing cavities are filled with mud to simulate a mud sleeve; the pipe joint sets are jacked and pressed, then the two sealing cavities are inflated and pressurized till air pressure is equal to stratum water pressure verified through testing, and whether mud overflows from the outside of the starting opening water stopping sealing device, joint positions in the pipe joint sets and the outside of the pipe-jacking receiving device is observed. According to the method, before construction is carried out, the sealing property of a pipe-jacking construction device can be tested in advance, and the test device is low in cost, convenient to operate and capable of testing the sealing property of the pipe-jacking construction device under the high water pressure condition.

Description

technical field [0001] The invention relates to a test method and a device for testing the water-tight sealing device of a starting hole, the sealing performance of pipe joints and the sealing performance of a receiving compartment of a pipe jacking construction device. Background technique [0002] As an important non-excavation technology, pipe jacking construction has been very common in China, and has been widely used in water supply and drainage, power communication, oil and gas and other municipal and energy pipeline construction. Due to the fast speed of pipe jacking construction, it is not harmful to the surrounding environment. The impact or impact is small, the construction site is small, the noise is low, and the advantages of being able to work deep underground will surely have a good development prospect in the next few decades. However, the starting and receiving of pipe jacking is an important risky stage of pipe jacking construction, especially in unfavorable...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/04

Inventor 张鹏王道伟黎轩马保松

Owner CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com