Mounting and detection method of multi-roll mill

A detection method and rolling mill technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reducing measurement accuracy, complex methods, error accumulation, etc., and achieve the goal of reducing detection errors, efficient and accurate positioning, and reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

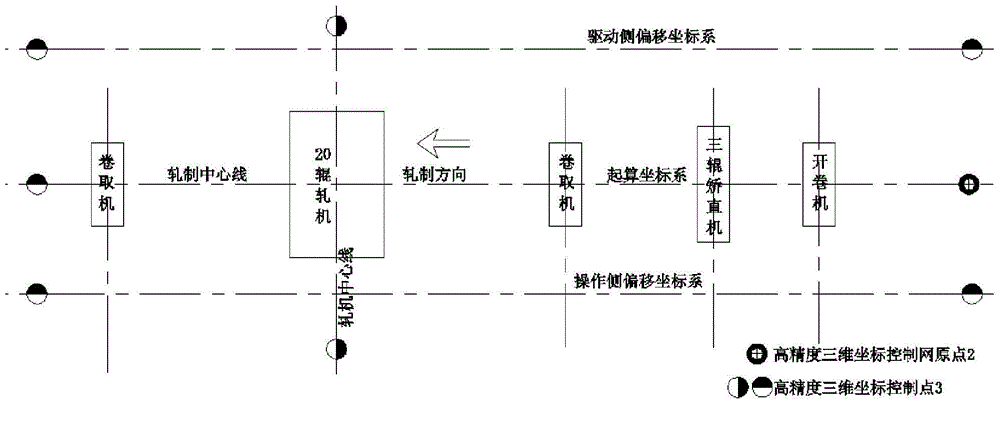

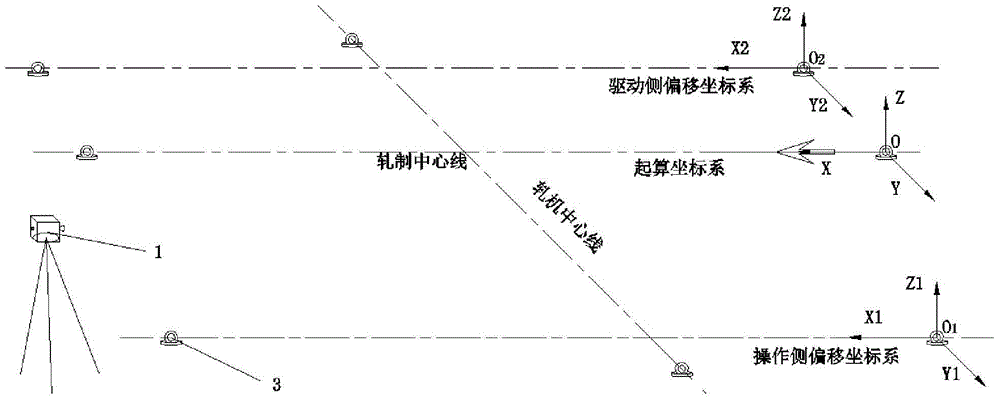

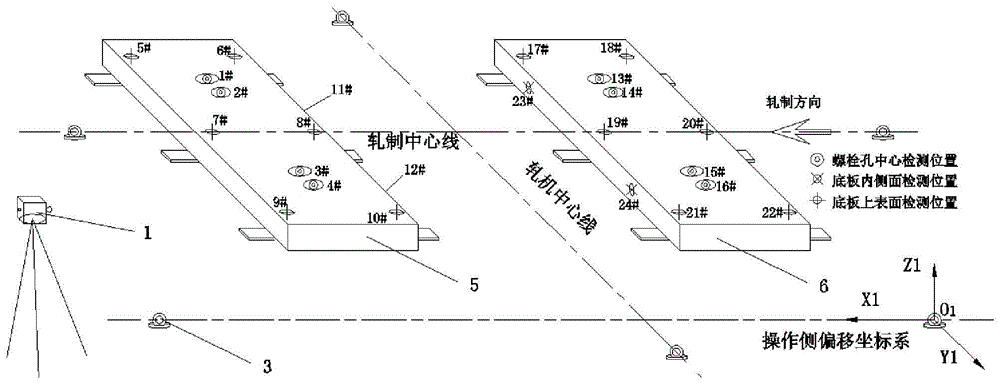

[0061] (1) Deploy a high-precision three-dimensional coordinate control network

[0062] See figure 1 , figure 2 , according to the coordinate control network and elevation control points of the main workshop, use the industrial-grade total station 1 to lay out the origin 2 of the high-precision three-dimensional coordinate control network and the high-precision three-dimensional coordinate control point 3 to establish a high-precision three-dimensional coordinate control network. Among them, the main rolling center coordinate system is used as the starting coordinate system, which is used as the reference; at the same time, a parallel offset coordinate system (working coordinate system) is established outside the main rolling coordinate system (operating side and transmission side). The implementation steps are as follows:

[0063] ① Based on the coordinate control network and elevation control points of the main factory building, and combined with the results of civil eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com