Combination molded tube capable of nesting spiral blades

A helical leaf and combined technology, applied in the field of combined helical leaf sleeve mold tube, can solve the problems of difficult to buy, inconvenient to use a ruler to measure, etc., and achieve the effect of less land occupation, less cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with the accompanying drawings.

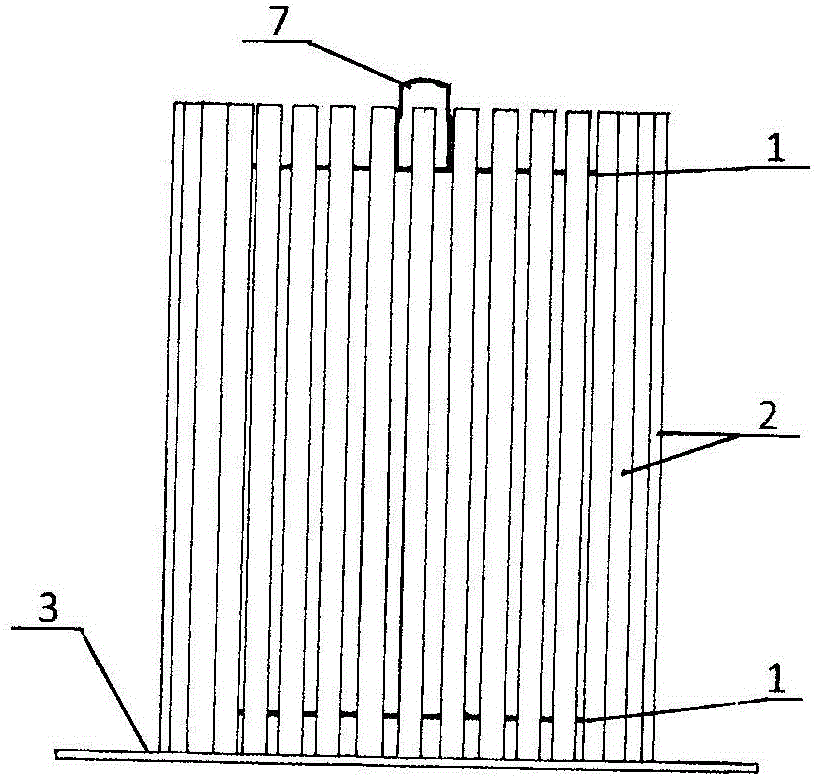

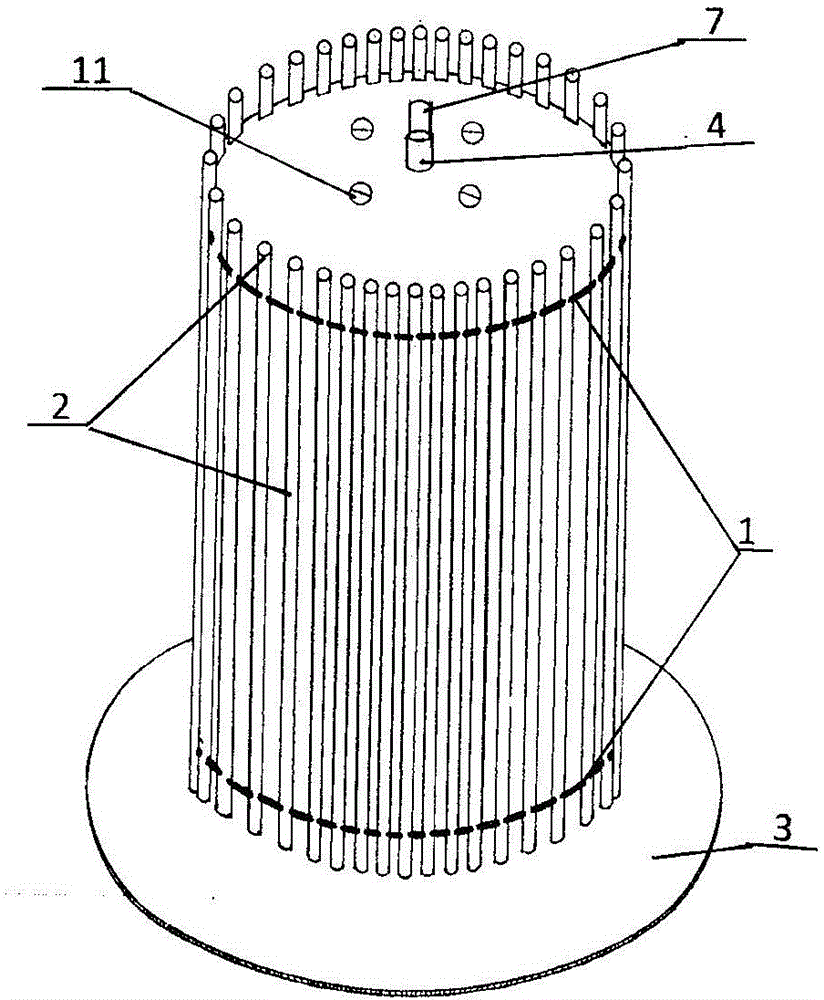

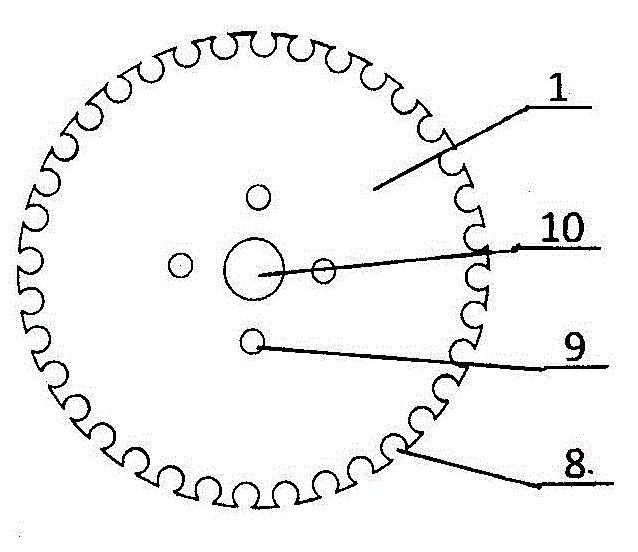

[0016] refer to Figure 1 to Figure 6 , the two assembled circular plates 1 are respectively installed on the upper and lower sides of the column 4, and the positioning hole 9 is fitted with the upper and lower positioning fixing plates 6 of the column by means of screws and 11, and the center hole 10 of the assembled circular plate 1 is fitted with the column, and its outer periphery The wire drill has a plurality of notched holes 8 for the insertion of many vertical small round bars 2, a handle 7 is installed on the top of the column for carrying and shifting, and a short tube 5 is installed in the center of the base 3 for fitting with the lower end of the column Connect and be convenient to the dismounting of column 4, purpose is for the convenience of installing a lower assembling circular plate, promptly inserts from the top of column lower end.

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com