Pressure resistant heat exchanger

A heat exchanger and pressure-resistant technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of heat exchanger structure damage, failure to use normally, and gas volume increase, etc., to achieve The heat exchange is sufficient, the structure is compact, and the effect of increasing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

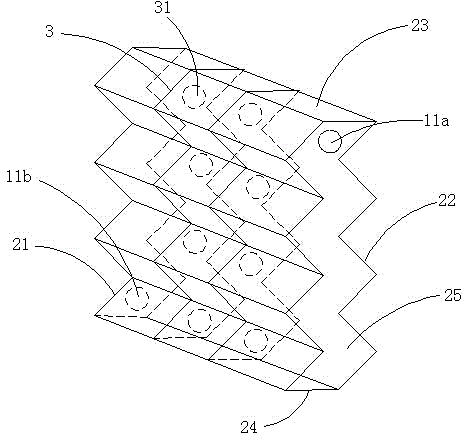

[0021] Such as Figure 1 to Figure 2 The embodiment shown,

[0022] Description of icon numbers: housing 1, liquid containing chamber 11, liquid inlet 11a, liquid outlet 11b, flue gas channel 12, flue gas inlet 12a, flue gas outlet 12b, bending monomer 2, peak 2a, valley 2b, The first bending plate 21, the second bending plate 22, the upper cover plate 23, the lower bottom plate 24, the side plates 25, the partition 3, and the through holes 31, the arrow direction in the figure indicates the flow direction of the flue gas.

[0023] Such as Figure 1 to Figure 2 Shown.

[0024] A pressure-resistant heat exchanger includes a shell 1, wherein the shell 1 is provided with bending monomers 2 at intervals, the bending monomer 2 is formed with a liquid chamber 11, and the bending monomer 2 is provided with In the liquid inlet 11a and the liquid outlet 11b, a number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com