water spray desuperheater

A technology of spraying water for temperature reduction and spraying holes, which is applied in the direction of superheating temperature control, steam superheating, steam generation, etc. It can solve the problems of low cooling water vaporization rate, water inflow of equipment, water hammer vibration, etc., and achieve the goal of overcoming water More steam and less, the effect of increasing the gasification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

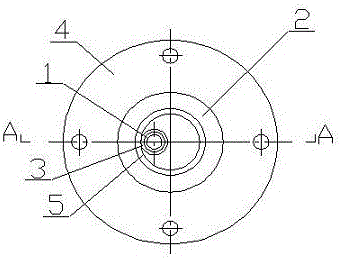

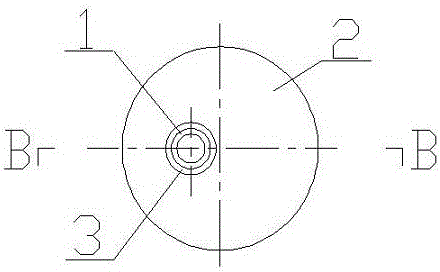

[0036] Such as Figure 14 with Figure 15As shown, a water spray desuperheater, said water spray desuperheater includes: nozzle 1, nozzle first flange 2, nozzle first atomizing sleeve 3, nozzle second flange 4, insertion pipe 5, Steam pipe section 6; the nozzle 1 is a stainless steel pipe, and its water inlet end is put into the eccentric hole 21 of the first flange 2 of the nozzle, and the seam is sealed and welded, and the other end of the nozzle 1 is sealed with a blocking plate Welding and sealing, at least one water spray hole 11 is arranged on the same side bus of the nozzle 1; the first flange 2 of the nozzle is installed in the round hole 41 of the second flange 4 of the nozzle, and the nozzle 1 Put into the steam pipe section 6 through the insertion pipe 5; the steam pipe section 6 has an inlet end 63 and an outlet end 64; a mixing plate 62 is arranged near the inlet end 63; the nozzle 1 is equipped with The first atomizing sleeve 3 of the nozzle, one end of which i...

Embodiment 2

[0038] Such as Figure 16 As shown, on the basis of Embodiment 1, at the port 54 where the insertion pipe 5 enters the middle part of the steam pipe section 6, the first elbow 73 is welded and connected to the evaporation pipe 7, and the joint is sealed and welded; The evaporation tube 7 is provided with an evaporation port 71 and a variable diameter joint 74; the secant of the evaporation port 71 provided on the evaporation tube 7 is located at 1 / 4 of the outer diameter of the evaporation tube 7; the aperture of the small end of the variable diameter joint 74 Equal to 3 / 4 of the diameter of the large end; the evaporation tube 7 is also provided with evaporation holes 72; the diameter of the evaporation holes 72 is 1 to 3 mm, and the spacing is 10 mm, and they are evenly distributed on the upper half of the evaporation tube 7 on the pipe wall.

Embodiment 3

[0040] Such as figure 1 As shown, on the basis of Embodiment 2, a second round hole 65 is set in the steam pipe section 6; the small diameter end of the reducing joint 74 of the evaporation pipe 7 is connected with the second elbow 81 and the drain pipe 8, The seams are sealed and welded; the drain pipe 8 extends out of the steam pipe section 6 through the second round hole 65 ; the seams of the drain pipe 8 and the second round hole 65 are sealed and welded.

[0041] Compared with the prior art, the advantage of Embodiment 1 is: the horizontal atomization grid is added, and the fan atomization nozzle provided on the first atomization sleeve of the nozzle guides the pressurized cooling water to impact on the atomization grid On the one hand, while increasing the atomization rate of the cooling water, it prevents the cooling water from spraying on the inner wall of the steam pipe, and the thickness ratio between the atomized group formed at the atomization grid and the superhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com