Poking rod control type valve core

A control type, valve core technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of difficult manufacturing, complex structure of the main body of the faucet, high cost, etc., to reduce the difficulty of casting, low implementation cost, structure Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

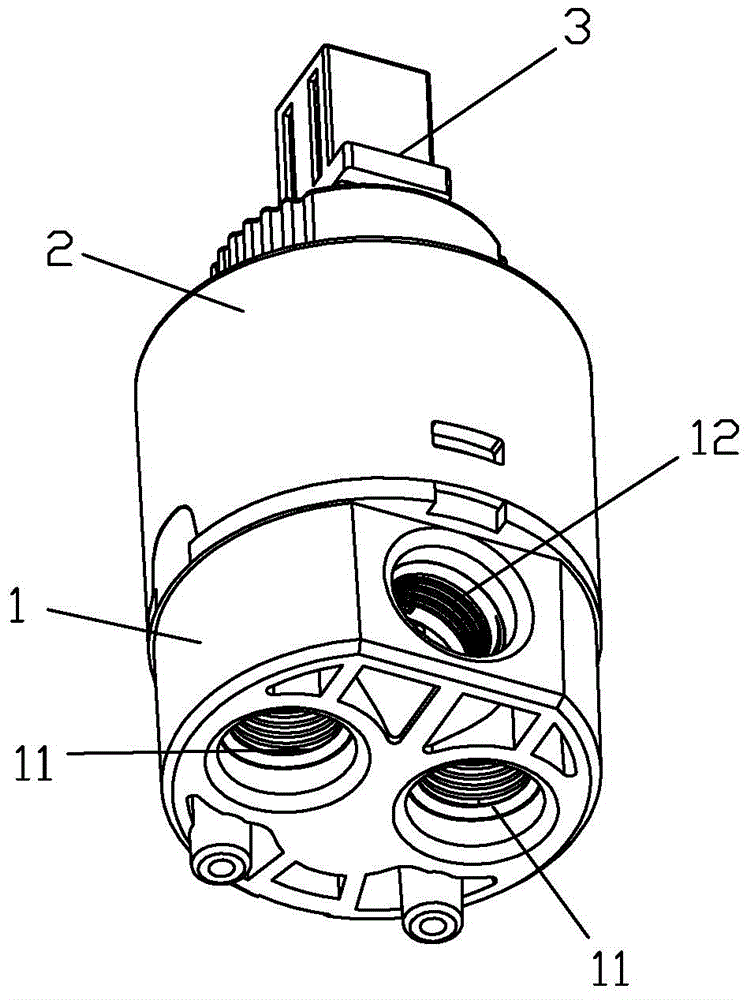

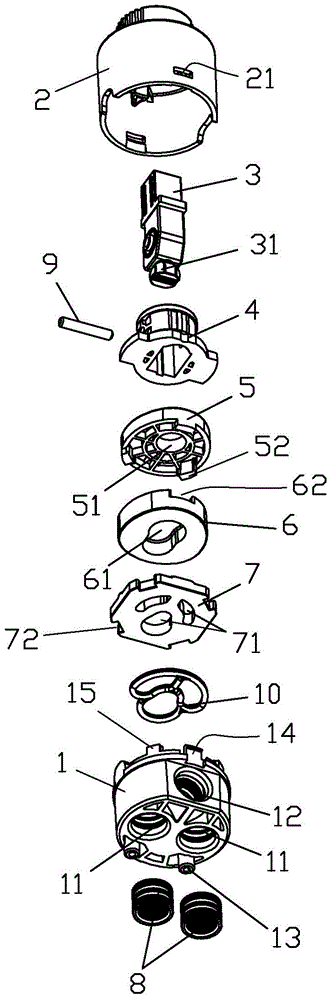

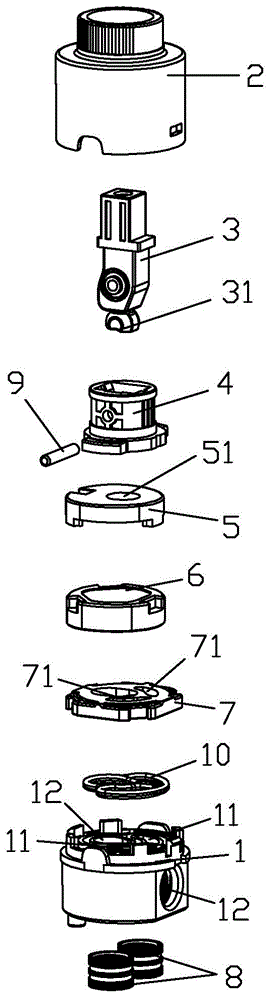

[0022] refer to Figure 1~Figure 7 , a lever-controlled valve core of the present invention, comprising a base 1 and a valve body 2 connected to the base 1, the valve body 2 is sequentially installed with a lever 3, a bracket 4, and a dial 5 from top to bottom , a ceramic movable piece 6 and a ceramic fixed piece 7, two water inlet channels 11 are provided on the bottom surface of the base 1 and axially pass through the base, and a water outlet channel 12 is provided on the side wall of the base 1 and extends to the base The upper end surface of the ceramic fixed piece 7 is fixed on the base 1, a sealing ring 10 can be placed between the ceramic fixed piece 7 and the base 1, and the ceramic fixed piece 7 has a water inlet channel 11 and a water outlet channel 12 Corresponding to the water hole 71, the ceramic moving piece 6 has an inner conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com