Brake disc

A disc and brake technology, which is applied in the field of floating brake discs, can solve the problems of affecting structural strength and safety in use, weak structural strength, and wear of the outer edge of the depression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

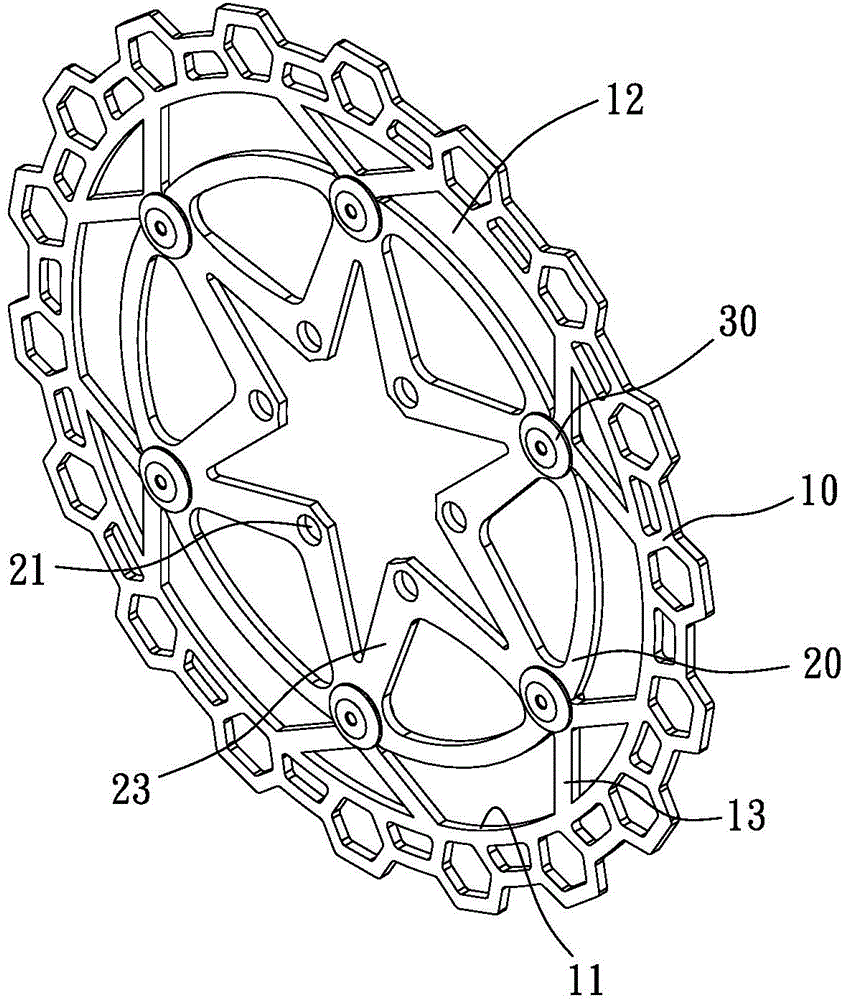

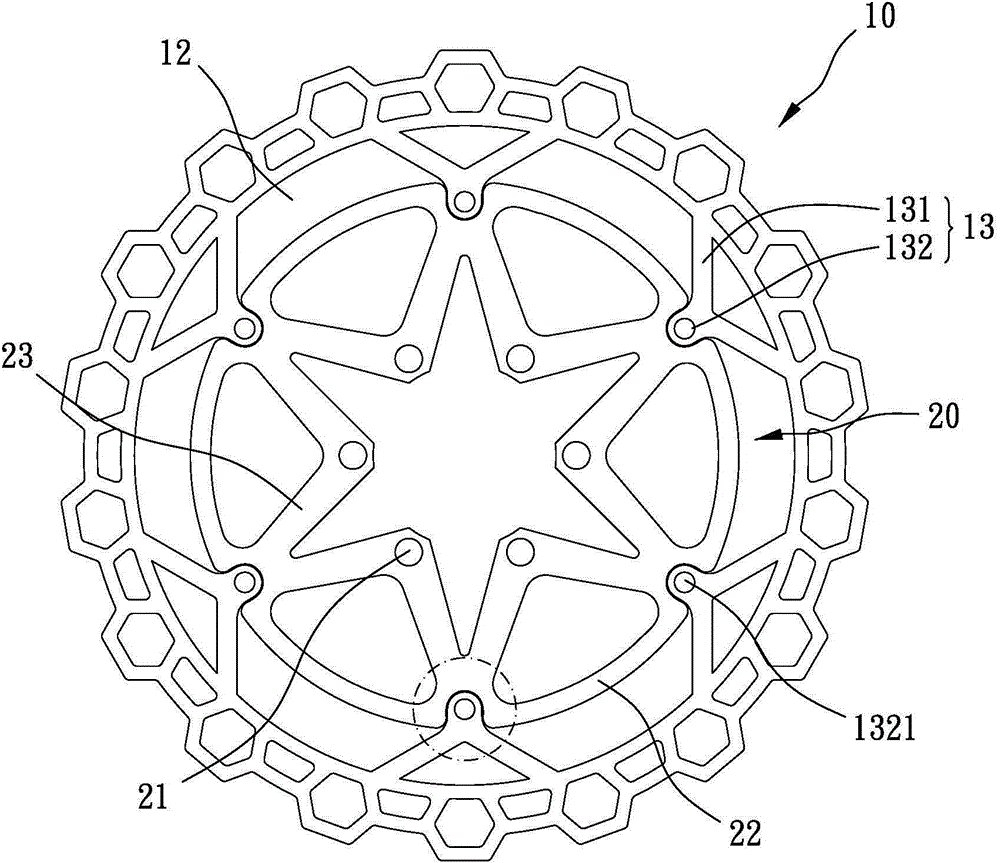

[0024] Please refer to figure 1 Referring to FIG. 5 , the present invention provides a brake disc, including an outer disc 10 , an inner disc 20 and a plurality of positioning elements 30 .

[0025] The outer disc 10 is generally ring-shaped and forms a perforation 12 in its center. The perforation 12 defines a central axis, and the central axis defines an axial direction. The outer disc 10 has an inner rim 11 surrounding the inner rim 11. The through hole 12 is formed, the inner ring edge 11 of the outer disk 10 is formed with a plurality of connecting bridges 13 arranged at intervals, and each connecting bridge 13 is formed to extend radially toward the central axis of the through hole 12, and the connecting bridges 13 are farther away from the outer disk. One end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com