Water-lubricated high-pressure plunger pump and hand-held high-pressure injection device

A high-pressure plunger pump and water inlet technology, applied in the hydraulic field, can solve the problems of difficult water flow channel design, inconvenient product portability, difficult design of water flow channel, etc., achieve good water flow channel design, good cooling, and increase design space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

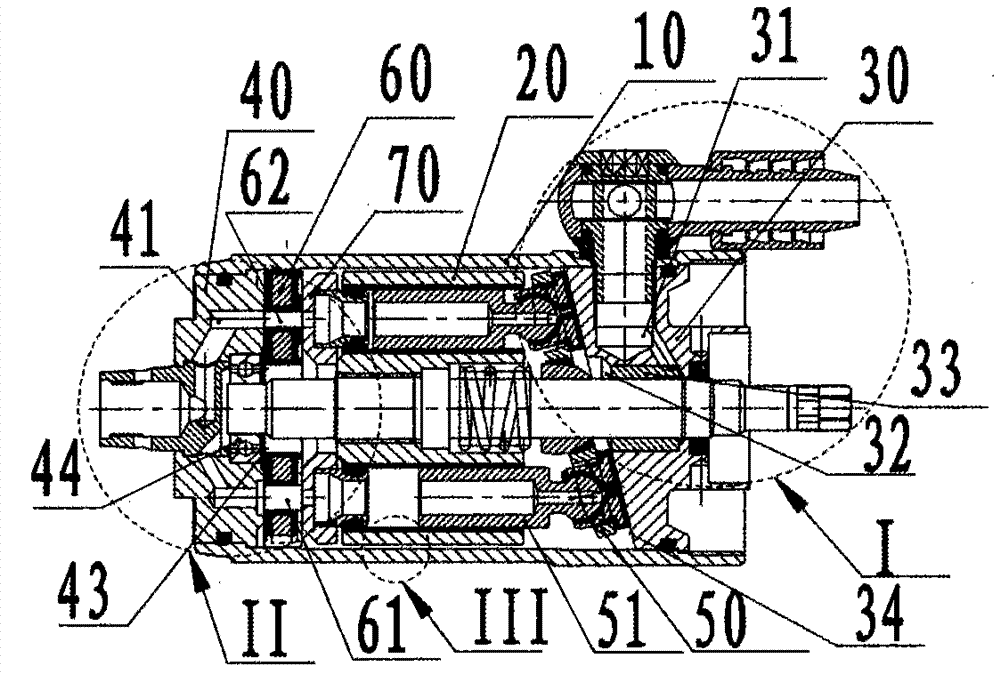

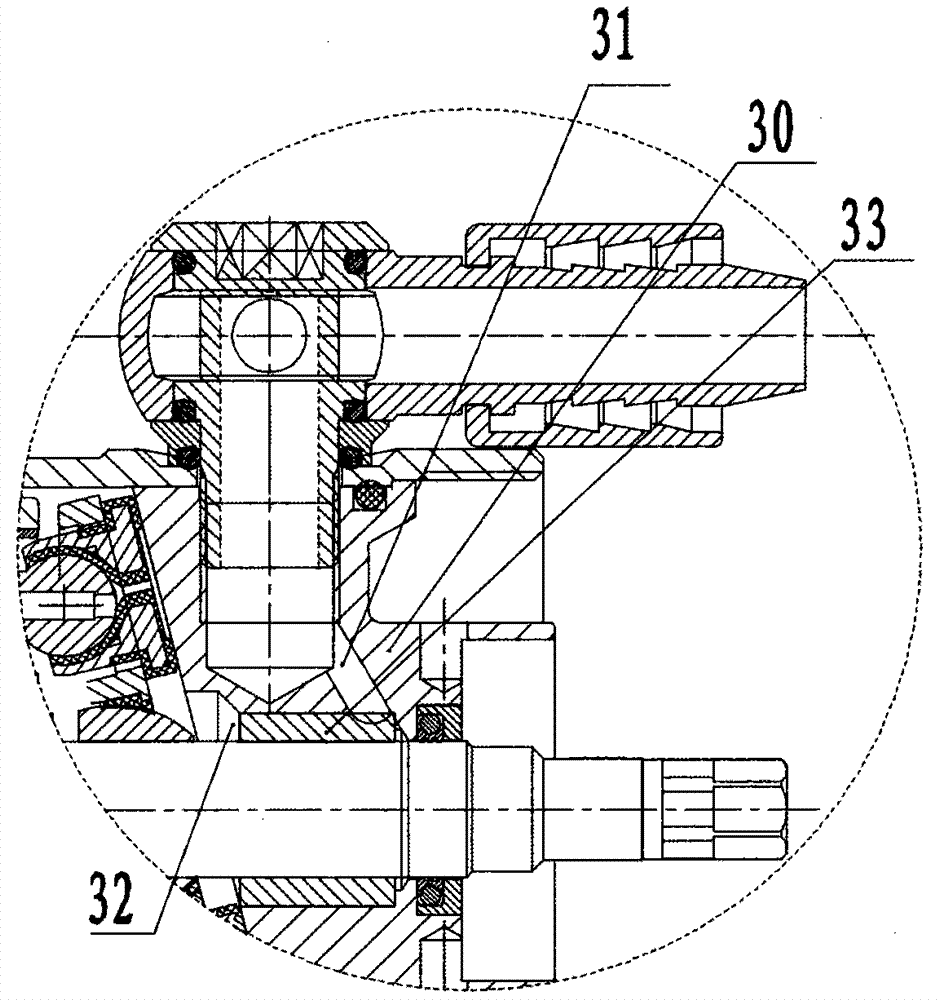

[0033] Embodiments of the present invention provide a water-lubricated high-pressure plunger pump, such as figure 1 As shown, the high-pressure plunger pump includes a housing 10 with a through hole, and a cylinder body 20 is arranged in the through hole, and cylinder holes 21 are arranged on the cylinder body according to a circular array; in order to facilitate the design of the flow channel, the present invention In the embodiment, the two end caps are respectively designed as the water inlet end cap 30 and the water outlet end cap 40, specifically as figure 1 As shown, one end of the through hole is provided with a water inlet cover 30, that is figure 1 The right end of the middle through hole is provided with a water inlet end cover 30, and a return plate 50 is arranged between the cylinder body 20 and the water inlet end cover 30. The return plate is provided with a plunger shoe assembly 51 inserted into the cylinder hole, through which the plunger slides. The piston mo...

Embodiment 2

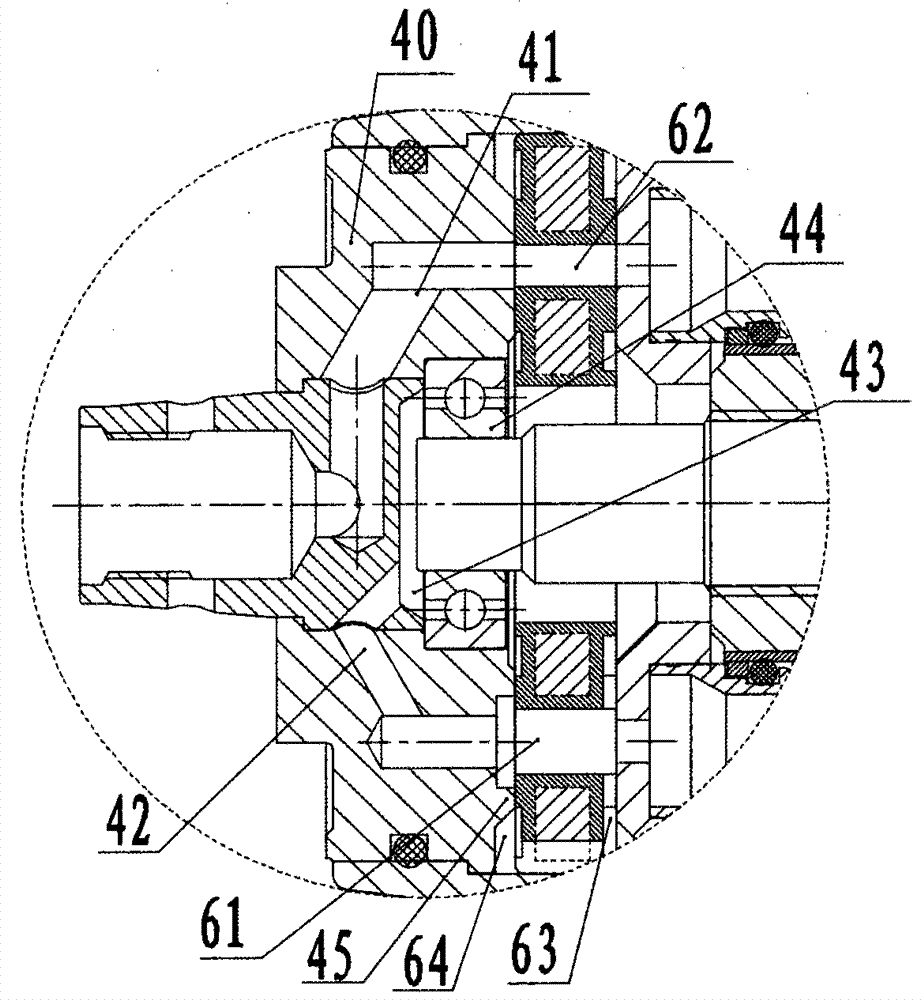

[0047] The embodiment of the present invention also provides a high-pressure plunger pump, specifically a water-lubricated high-pressure plunger pump for lubricating bearings, such as figure 1 As shown, it includes a housing 10 with a through hole, a cylinder body 20 is arranged in the through hole, cylinder holes 21 are arranged on the cylinder body 20 according to a circular array, and water inlet end caps 30 are respectively provided at both ends of the through hole. and the water outlet cover 40, a distribution plate 60 is provided between the cylinder body 20 and the water outlet cover 40, the water inlet cover 30 is provided with a water inlet channel 31 that can communicate with the outside, and the water outlet cover 40 is provided with a The water outlet channel 41 communicates with the outside, and the water inlet channel 31 communicates with the water inlet hole 61 of the distribution plate through the side gap 22 between the cylinder body and the casing. In order t...

Embodiment 3

[0056] An embodiment of the present invention provides a high-pressure plunger pump, specifically a water-lubricated high-pressure plunger pump with lubricated bearings, such as figure 1 As shown, the high-pressure plunger pump includes a housing 10 with a through hole, and a cylinder body 20 is arranged in the through hole, and cylinder holes 21 are arranged on the cylinder body 20 according to a circular array, and the two ends of the through hole are respectively provided with The water inlet end cover 30 and the water outlet end cover 40, a return plate 50 is arranged between the cylinder body 20 and the water inlet end cover 30, and a plunger shoe assembly 51 inserted into the cylinder hole is provided on the return plate 50; the water inlet The end cover 30 is provided with a water inlet channel 31 that can be communicated with the outside. In the present invention, the water inlet channel 31 is provided on the end cover with a return plate, so that the water flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com