Continuous pad-steam dyeing loose fiber dyeing process

A bulk fiber, dyeing and padding technology, applied in liquid/gas/steam fiber/sliver/roving processing, continuous processing of textile materials, liquid/gas/steam textile material processing, etc., can solve the problem of time-consuming, production and operation costs High, low production efficiency and other issues, to achieve the effect of reducing production costs, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by means of the accompanying drawings and examples.

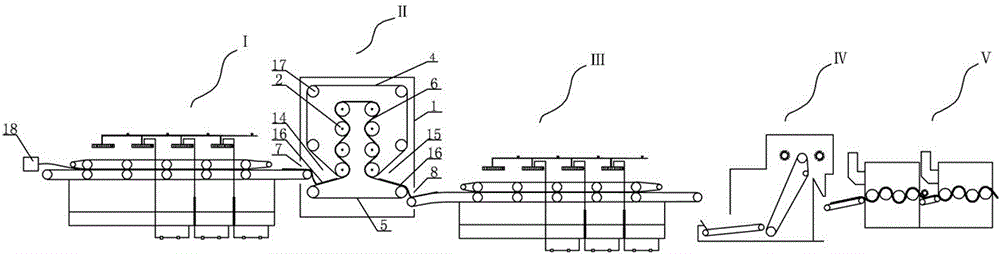

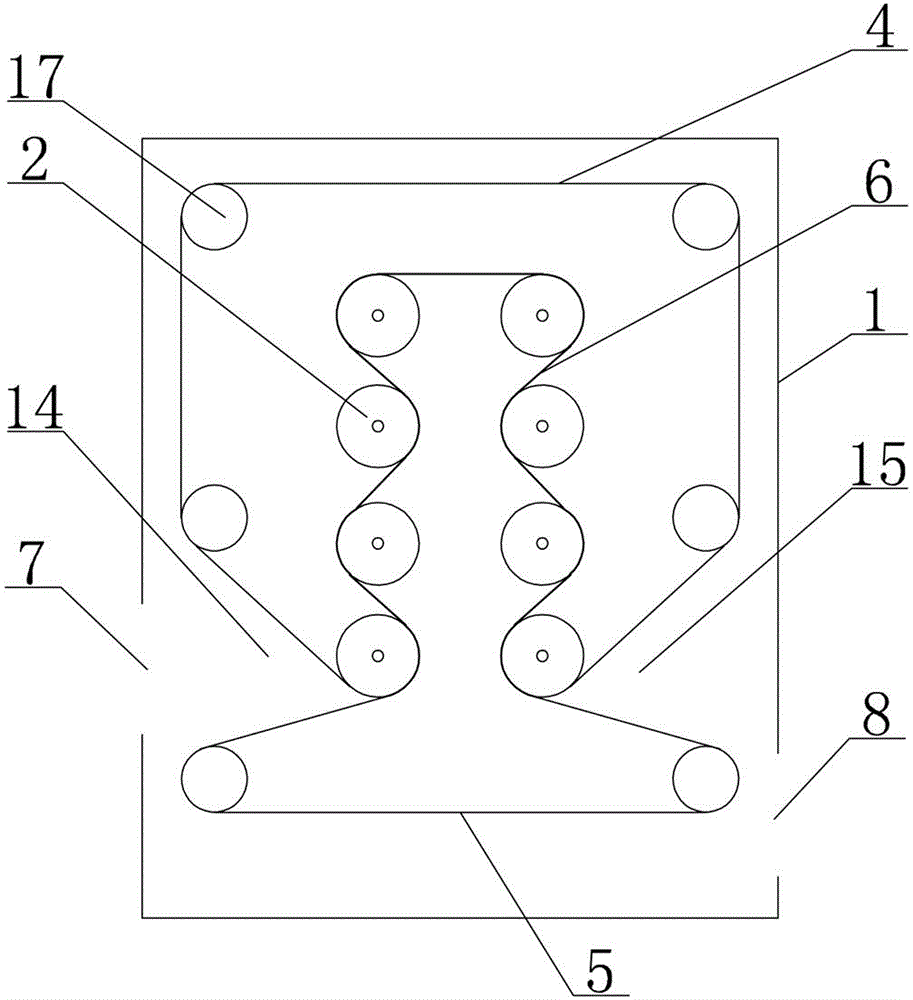

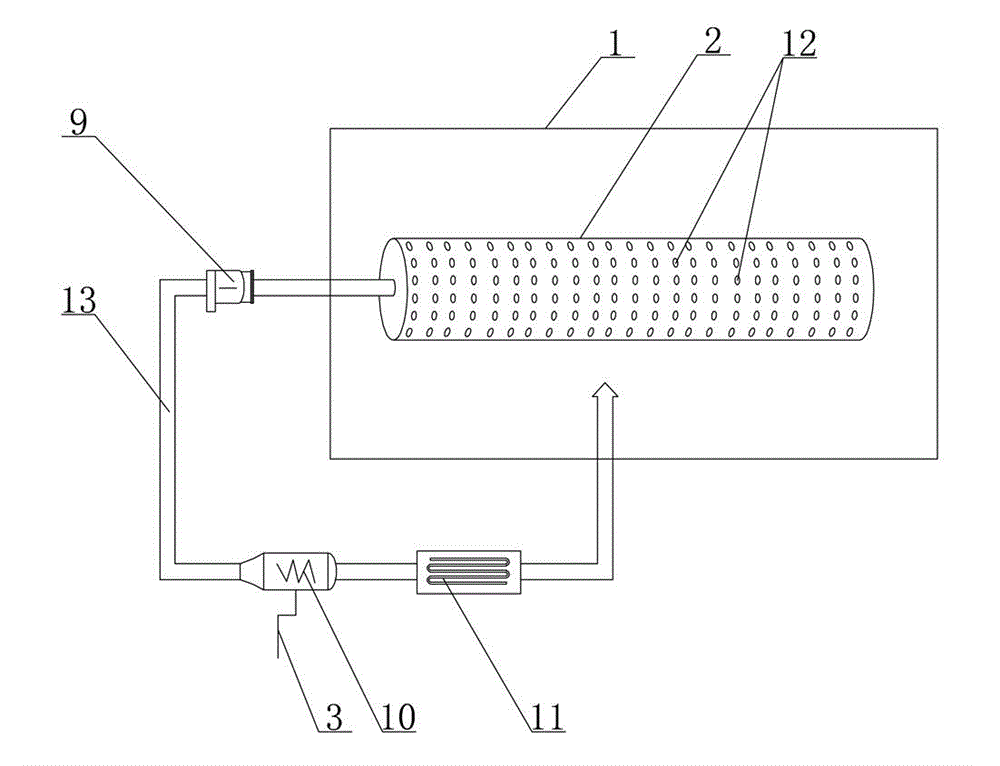

[0024] like Figure 1-Figure 3 Shown: the structure of the corresponding dyeing pad steaming continuous type loose fiber dyeing device that realizes the dyeing pad steaming continuous type loose fiber dyeing process of the present invention is as follows: a kind of dyeing padding steaming continuous type loose fiber dyeing device includes successively arranged drench padding Dyeing machine Ⅰ, steaming device Ⅱ, rolling washing machine Ⅲ, opening machine Ⅳ and dryer Ⅴ.

[0025] The above-mentioned padding dyeing machine I has applied for a patent, the patent number is: 201420012283.7, which mainly achieves the purpose of dyeing through repeated padding processes. The shower rolling washing machine III has also applied for a patent, the patent number is: 201420012281.8, which mainly realizes the purpose of water washing through the repeated shower rolling process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com