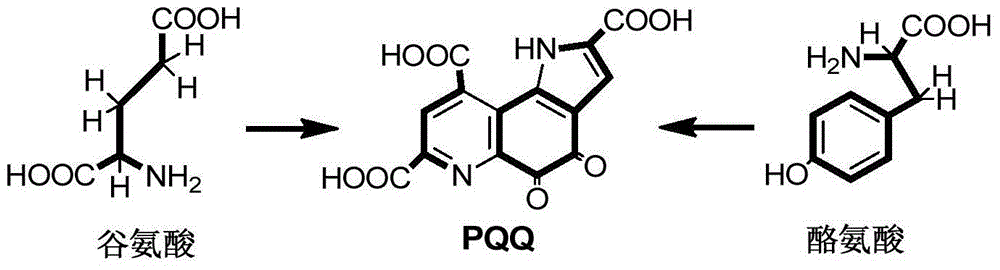

Synthetic method of pyrroloquinoline quinone

A technology of pyrroloquinoline quinone and synthesis method, which is applied in chemical recovery, organic chemistry and other directions, can solve the problems of harsh reaction conditions, high price, unclear reaction mechanism, etc., and achieves fast reaction speed, high reaction yield, and reduced risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 2-methoxy-5-nitroaniline hydrochloride was used as raw material, dissolved in water, treated with alkali, and then extracted with ethyl acetate to obtain compound 1

[0053] 20g of 2-methoxy-5-nitroaniline hydrochloride (purity 84.3%) was added to a 500ml beaker, 200ml of water was added and stirred, most of the raw materials were dissolved, and NaOH was added to adjust the pH of the aqueous phase to 8. Extracted three times with ethyl acetate, the organic phase was extracted with saturated NaCl, added anhydrous NaSO4 and dried, filtered and then dried by rotary evaporation to obtain 11.6 g of compound 1 as an orange-red solid, with a yield of 83.7% (TLC:PE / EA=5:1 ).

Embodiment 2~10

[0054] Examples 2-10 Preparation of Heteropolyacid Ionic Liquid Used in Compound 1 Synthesis of Compound 2

Embodiment 2

[0056] Add 1,3-propane sultone (0.05mol, 6.1g) and 50ml ethyl acetate into a 100ml flask, stir and keep it warm in an oil bath at 50°C for 30min. Slowly add N-methylimidazole (0.055mol, 4.5g, 4.4ml) dropwise, and keep the reaction for 24 hours after the dropwise addition. After the reaction was finished, it was cooled, filtered, and the filter cake was washed 3 times with ethyl acetate, and vacuum-dried for 48 hours to obtain 10.6 g of white solid 1-(3-sulfonic acid) propyl-3-methylimidazolium salt (MIMPS). The rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com